Novel rock crusher shell body

A crusher and rock technology, applied in the field of rock crushing, can solve problems such as pollution, strong vibration of the crusher, fretting wear noise, etc., and achieve the effects of lower noise pollution, improved life, and reduced fretting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

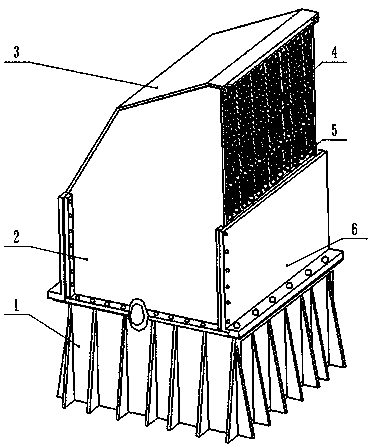

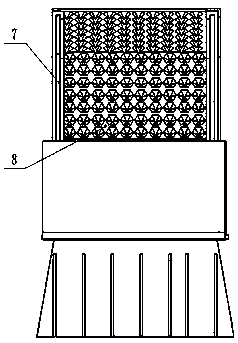

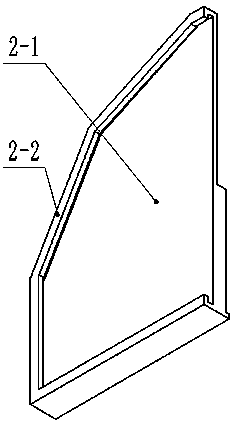

[0033] Such as Figure 1-10 As shown, a new type of rock crusher housing includes a base 1, side plates 2, top plate 3, door 4, front and rear wear plates 5, front and rear baffles 6, side wear plates 7 and counterattack plates 8; The side plate 2, the top plate 3, and the front and rear baffles 6 are located on the upper part of the base 1, and are connected by bolts; In the grooves of the plate 2 and the top plate 3, and further fixed by bolts;

[0034] Further, the door 4 has two layers, including an outer high manganese steel chain door 4-1 and an inner rubber door 4-2; the length of the high manganese steel chain door 4-1 is greater than that of the rubber door 4-1. 2, and are all installed on the front end of the top plate 3, the top plate 3 includes a top plate groove 3-1 and a top plate base 3-2;

[0035] Further, the backs of the front and rear wear plates 5 and the side wear plates 7 all have regular hexagonal rubber buffer protrusions 7-2;

[0036] Further, the c...

Embodiment 2

[0043] A rock breaker, comprising the novel rock breaker housing as described in Embodiment 1.

[0044] The working principle of the present invention is: when installing, first install the side wear-resistant plate 7 in the groove 2-2 of the side plate 2, and fix the two through bolts; install the counterattack plate 8 in the groove 3 of the top plate 3 -1, and the counterattack plate 8 and the top plate 3 are fixed by bolts; the front and rear wear plates 5 are installed in the grooves of the front and rear baffles 6, and the front and rear wear plates 5 and the front and rear baffles 6 are fixed by bolts; the side Plate 2, counterattack plate 8, and front and rear baffles 6 are fixed together with bolts, rubber door 4-2 and high manganese steel chain door 4-1 on the door 4 are installed in sequence, and finally the above parts are installed on the base by bolts 1; when the crushed stone hits the front and rear wear plates 5, side wear plates 6 and impact plates 8 under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com