Micro turbine for aero-engine

A technology of aero-engines and turbines, which is applied in the direction of engine components, machines/engines, and air transportation, etc. It can solve the problems of easy backward movement of turbine blades and achieve the effects of small vibration stress, high positioning tightness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

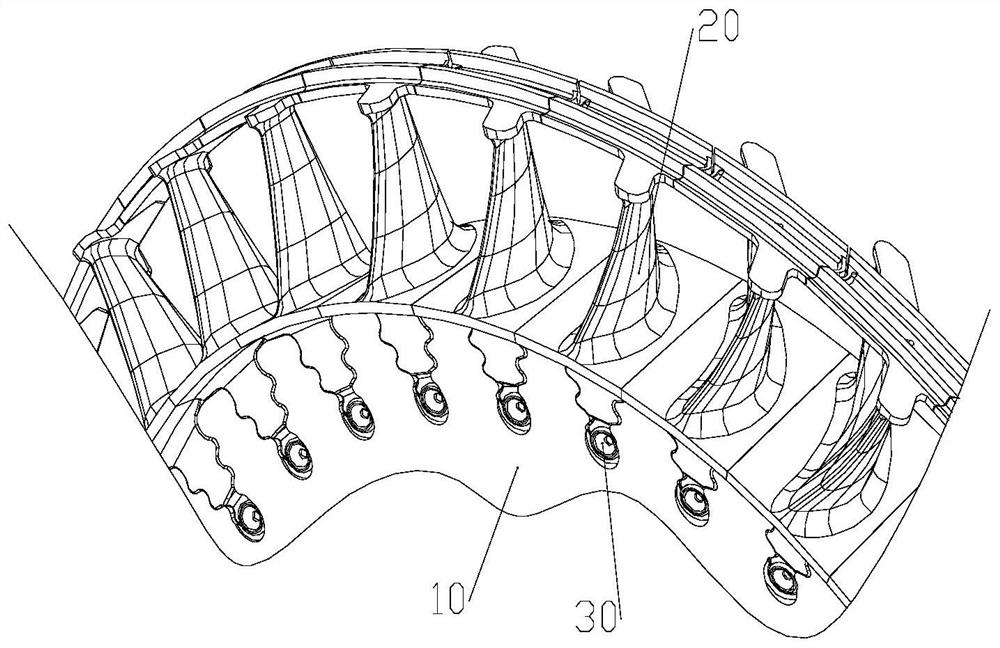

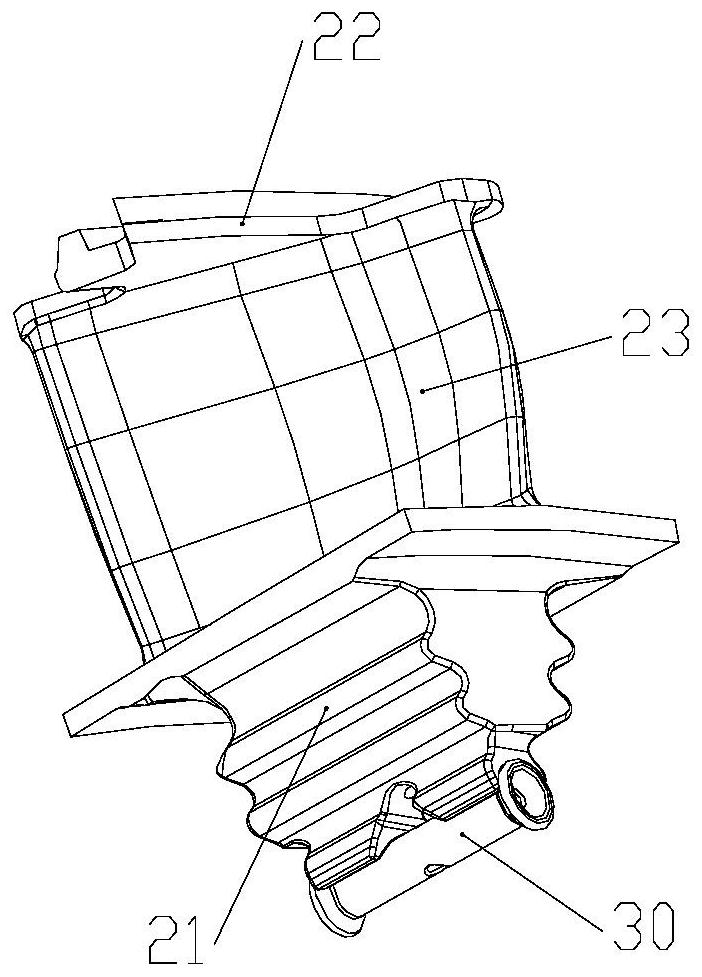

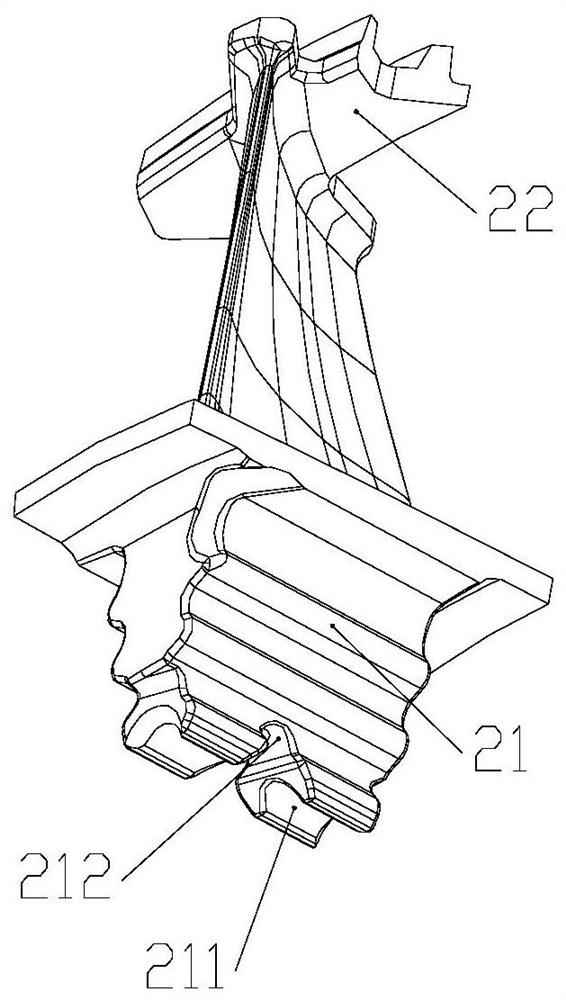

[0028] refer to figure 1 A preferred embodiment of the present invention provides a micro-turbine for an aero-engine, comprising a turbine disk 10 and turbine blades 20 arranged successively on the turbine disk 10 along the circumference of the turbine disk 10, the micro-turbine also includes a The blade 20 is locked to the locking pipe 30 in the corresponding tenon groove 101 on the turbine disk 10. The locking pipe 30 is installed at the connection position between the small end of the tenon 21 of the turbine blade 20 and the tenon groove 101, and the locking pipe 30 It is deformed under the action of external force riveting, so as to be squeezed into the tenon 21 and the tenon groove 101 at the same time to lock the turbine blade 20, thereby preventing the turb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com