Fixing device

A fixing device and screw fixing technology, which is applied in threaded fasteners, thin plate connections, connecting components, etc., can solve problems such as deformation of the inner hook A2, difficulty in assembly, cracking and bending of the inner hook A2 or flange B1, and achieve accurate Reliable snap-fit assembly, high positioning tightness, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The detailed description is as follows in conjunction with the embodiments and accompanying drawings.

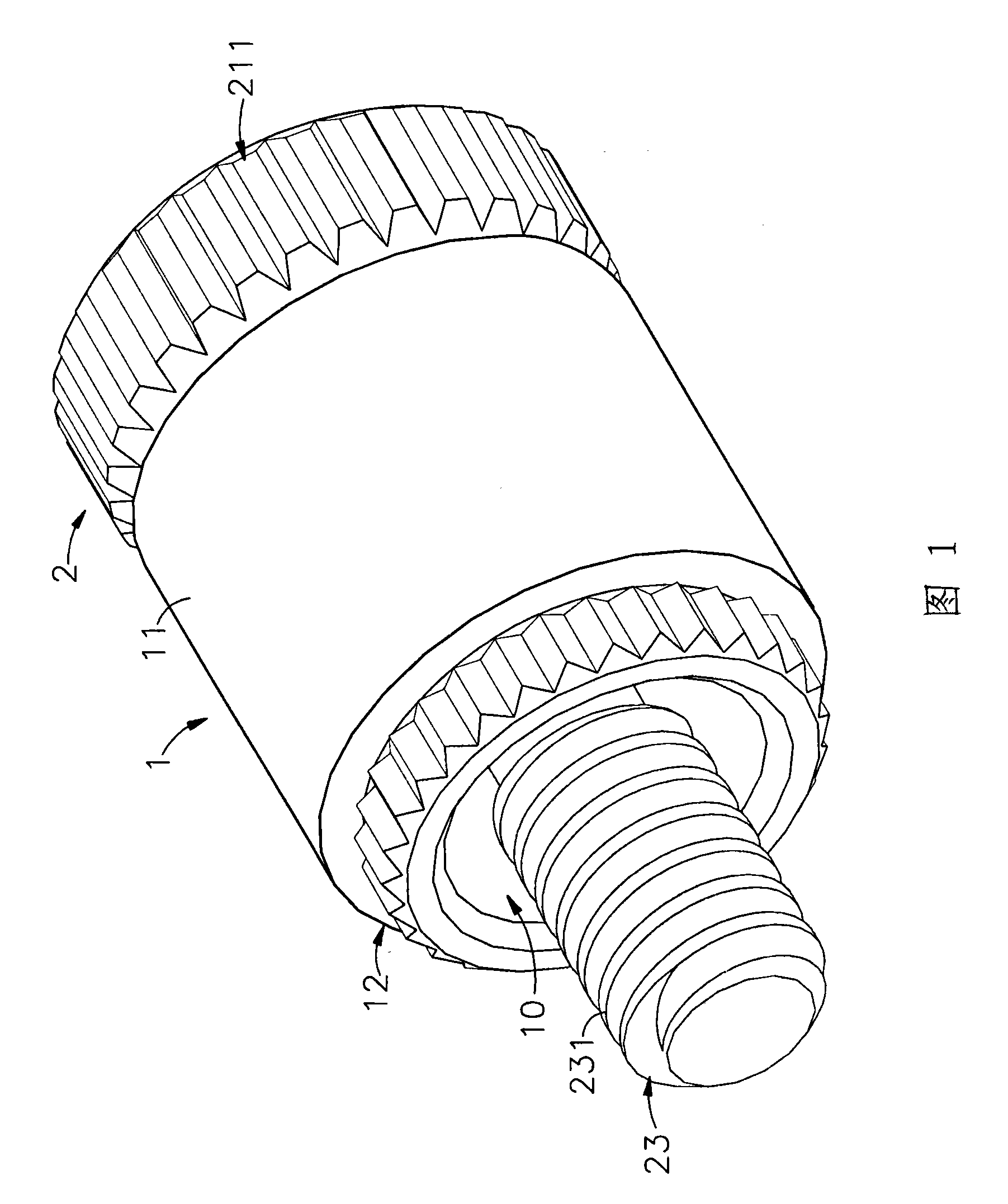

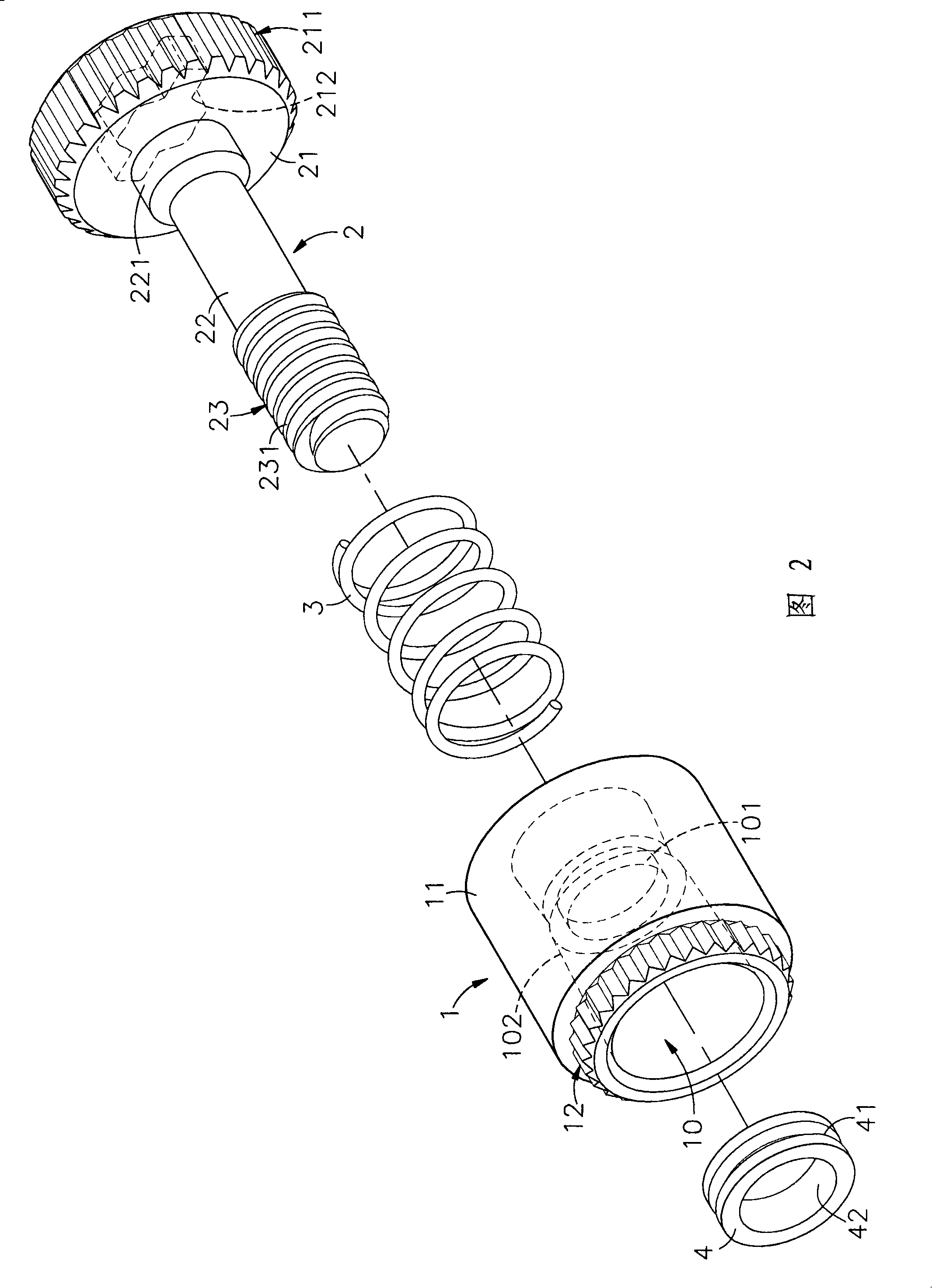

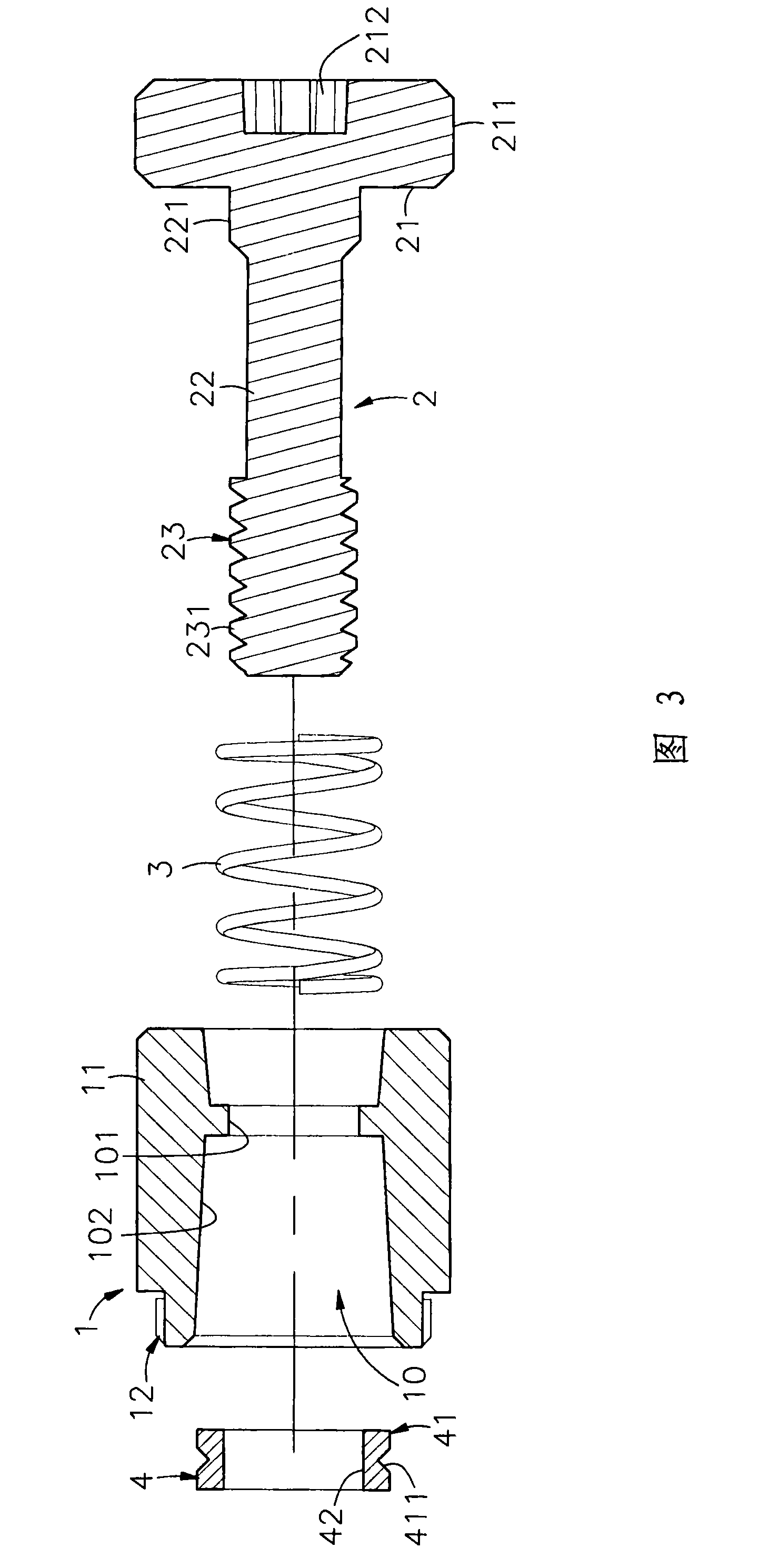

[0062] Please refer to Fig. 1, Fig. 2 and Fig. 3, which are the three-dimensional appearance diagram, the three-dimensional exploded view and the side view sectional view before assembly of the present invention. It can be clearly seen from the figure that the fixing device of the present invention has The receiving pipe body 1, the screw assembly 2, the spring 3 and the stop collar 4 are composed, and the structure of the present invention is described in detail below; wherein:

[0063] The receiving pipe body 1 is formed with a perforation 10 in the hollow pipe body 11, and the inner wall surface of the perforation 10 is protruded with a ring convex part 101 and an inwardly tapered slope 102, and another side of the receiving pipe body 1 is provided with a Engagement part 12.

[0064] The screw fixing component 2 is formed with an engaging portion 211 on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com