Tire gauge part

A technology for tire pressure gauges and parts, which is applied in the field of tire pressure gauge parts to achieve the effects of convenient use, reasonable application cost and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

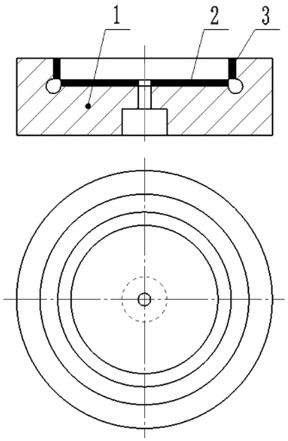

[0016] figure 1 It is a structural schematic diagram of a tire pressure gauge part in Embodiment 1 of the present invention,

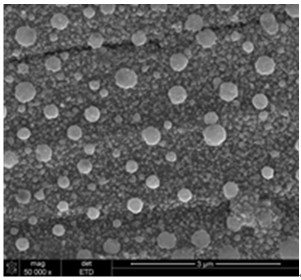

[0017] figure 2 It is a scanning electron micrograph of a composite material layer of a tire pressure gauge part sample in Example 1 of the present invention; in the drawings, 1 is the matrix material, 2 is the composite material layer, and 3 is the composite material layer.

[0018] The tire pressure gauge part of the present invention is characterized in that: after grinding, cleaning, degreasing, and rust removal on the corresponding surface of the tire pressure gauge part, after fine grinding, polishing, ultrasonic cleaning, and drying, the inside of the yoke part A composite material layer containing more than 60% (Wt%) of indium and more than 8% (Wt%) of iron and more than 70% (Wt%) of indium and iron is provided on the surface of the bottom of the hole. A bump crystallite, each bump crystallite has a height of more than 100nm and less than 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com