Indium composite microcrystal bump texture

A bump and microcrystalline technology is applied in the field of indium composite microcrystalline bump texture to achieve the effects of improving connection reliability, good heat dissipation performance and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

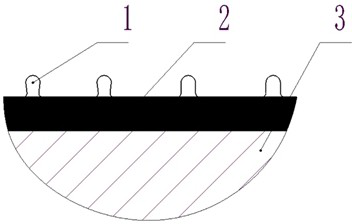

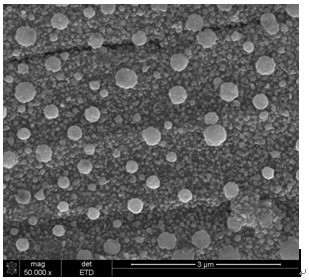

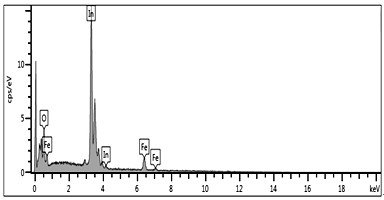

[0016] figure 1 It is a schematic structural diagram of the indium composite microcrystalline bump texture in Example 1 of the present invention, figure 2 is the scanning electron microscope image of the indium composite microcrystalline bump texture sample of Example 1 of the present invention, image 3 For embodiment 1 of the present invention figure 2 The energy spectrum corresponding to the indium composite microcrystalline bump texture sample in the figure, 1 is the bump crystallite, 2 is the composite material layer, and 3 is the part.

[0017] The indium composite microcrystalline bump texture of the present invention is characterized in that: on the surface of the part, a structure containing more than 60% (wt%) of indium and more than 8% (wt%) of iron and more than 70% (wt%) of indium and iron together is set on the surface of the part. ) composite material layer, on the surface of the composite material layer, there are many bump crystallites, the top of each bum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com