Assembly method capable of achieving hole and bush extrusion strengthening twice

An assembly method and secondary extrusion technology, applied in the field of metal parts assembly, can solve problems affecting flight safety, fretting wear, and uncertainty, so as to improve the life of key holes, reduce fretting wear, and prevent initial damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below.

[0033] Specific steps are as follows:

[0034] Step 1: Preparation before extrusion

[0035] 1) Check the parts before extrusion, and the parts should meet the following requirements:

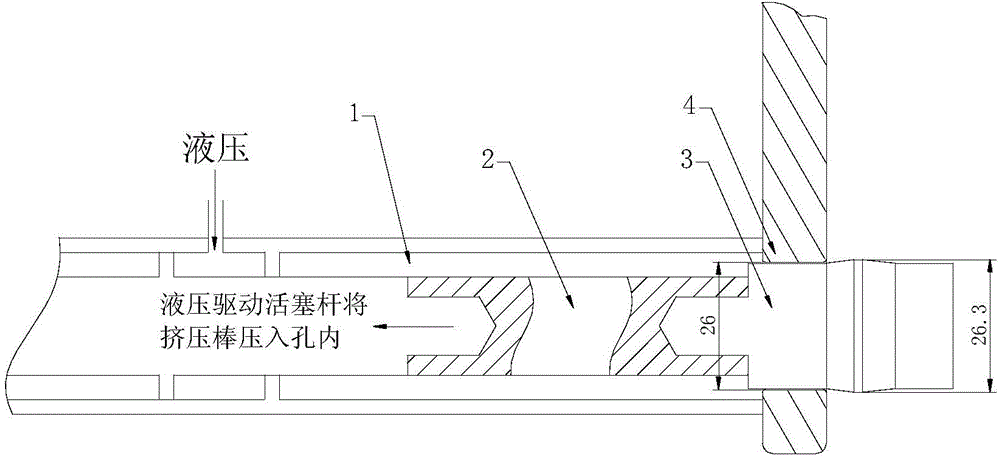

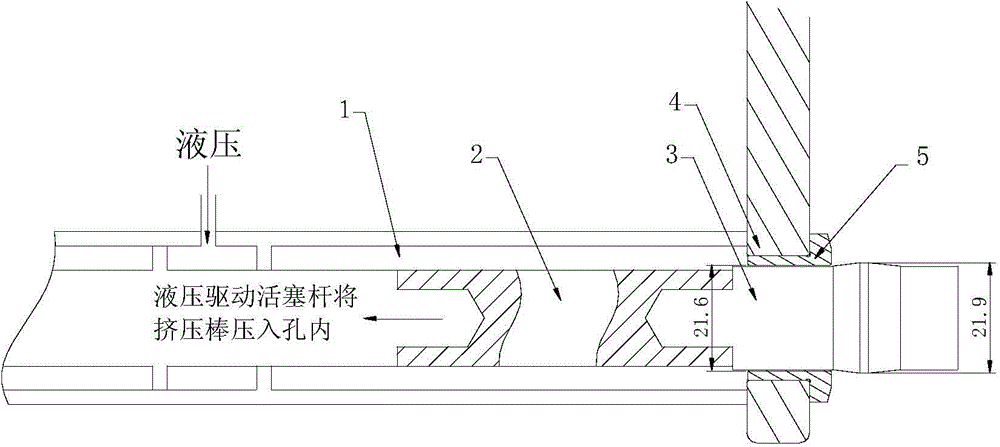

[0036] a) Complete the machining of the to-be-extruded hole 4 and the to-be-extruded bushing 5 according to the drawings, and meet the specified surface roughness requirements;

[0037] b) cleaning the surface of the hole wall of the hole 4 to be squeezed;

[0038] 2) Check the oil circuit and air circuit system of extrusion gun 1.

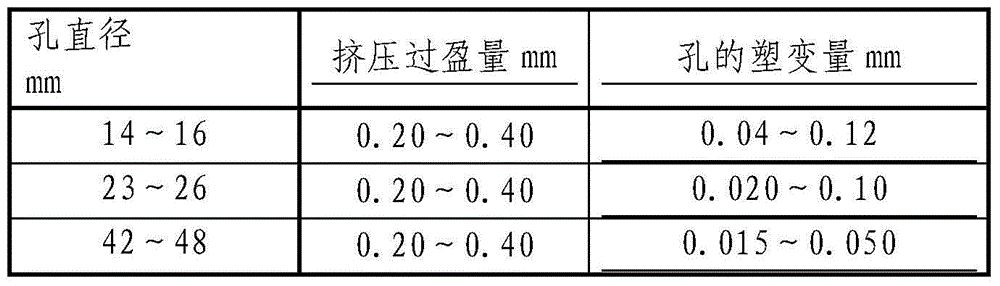

[0039] 3) Parameter setting: Before the first extrusion strengthening, the interference between the extrusion rod 3 and the hole 4 is selected according to the design requirements; the second extrusion strengthening after the bushing 5 is assembled, The gap between the reinforced front bushing 5 and the hole 4, and the interference between the extruded rod 3 and the inner hole of the bush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com