Thin-sized hot-continuous-rolled steel for furniture and method for producing same

A production method and hot continuous rolling technology are applied in the field of steel material production, which can solve the problems of inability to achieve stable production and low rolling temperature, and achieve the effects of high strength and toughness matching, enhanced safety, good elongation and cold bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

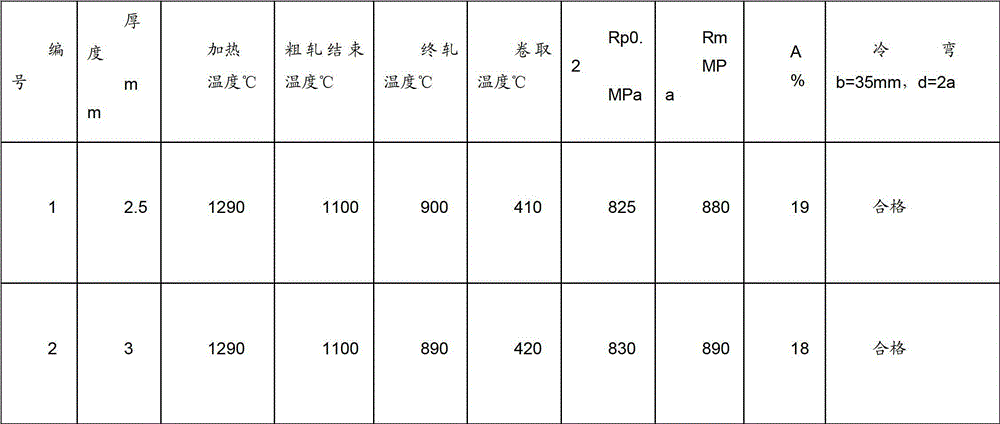

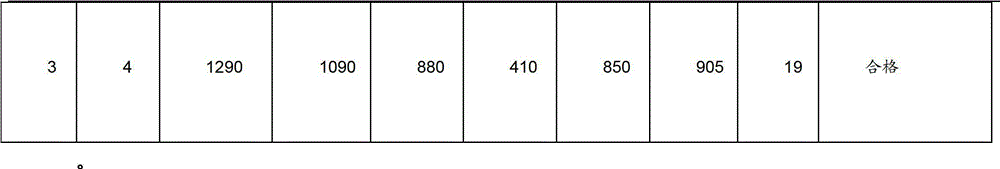

[0042] Table 1 shows the composition system of the thin-gauge hot-rolled furniture steel provided in Embodiment 1 of the present invention.

[0043] Table 1

[0044] C

Embodiment 2

[0046] The production method of the thin-gauge hot-rolled furniture steel provided in Embodiment 2 of the present invention is to produce 2-4mm thin-gauge 800MPa grade furniture steel according to the chemical composition of Embodiment 1, and the production process route adopts 220 tons of converter smelting-LF refining ——RH vacuum treatment - continuous casting - furnace reheating - rough rolling - 7-stand finish rolling - laminar cooling - coiling.

[0047] The molten steel smelted in a 220-ton converter and refined outside the furnace is continuously cast into billets, and rolled in the 1580 hot continuous rolling production line. The reheating temperature is controlled at 1280-1300°C, and the finishing temperature of rough rolling is controlled at 1080°C-1100°C. , Use edge induction heater between rough rolling and finishing rolling process, its heating temperature is 1100-1150℃, control finish rolling and finish rolling temperature at 880℃~900℃, after rolling, it will be c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com