A kind of glass ceramics with high crystal content and preparation method thereof

A technology of glass-ceramics and crystal content, which is applied in the field of glass manufacturing, can solve the problems of reducing the practicability of glass-ceramics, the proportion of crystal phase of glass-ceramics is low, and reducing the performance of glass-ceramics, etc., so as to achieve strong practicability , Versatility, enhance the effect of anti-destructive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

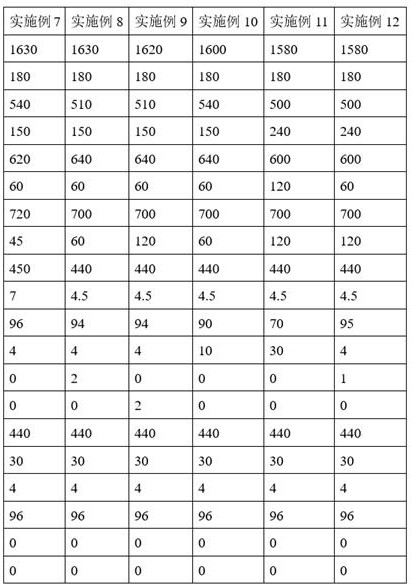

[0033] The present invention also provides a method for preparing glass-ceramics with high crystal content, comprising the following steps:

[0034] S1: Melt glass at a temperature of 1500°C to 1600°C, and obtain plain glass with certain dimensions;

[0035] S2: place the plain glass obtained in step S1 at a temperature T1 of 500°C to 550°C, heat for 1h to 5h, then place the plain glass at a temperature T2 of 550°C to 700°C, and heat it for 1h to 6h , and then put it under the condition that the temperature T3 is 700°C~800°C, and heat it for 0~4h;

[0036] S3: Repeat step S2 at least twice to prepare glass ceramics.

[0037] Specifically, in the embodiment of the present invention, after step S3 in the method for preparing glass-ceramics with high crystal content, step S4 is further included: placing the glass-ceramics obtained in step S3 in a solution containing sodium nitrate, nitric acid In the salt bath of at least one of potassium, sodium carbonate and potassium carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com