Grease composition for automobile wheel bearing

a technology for automobile wheels and grease compositions, applied in the petroleum industry, lubricant compositions, additives, etc., can solve problems such as flaking, unsatisfactory grease compositions, and phenomenon called fretting, and achieve the effect of reducing fretting wear and prolonging the flaking life of wheel bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

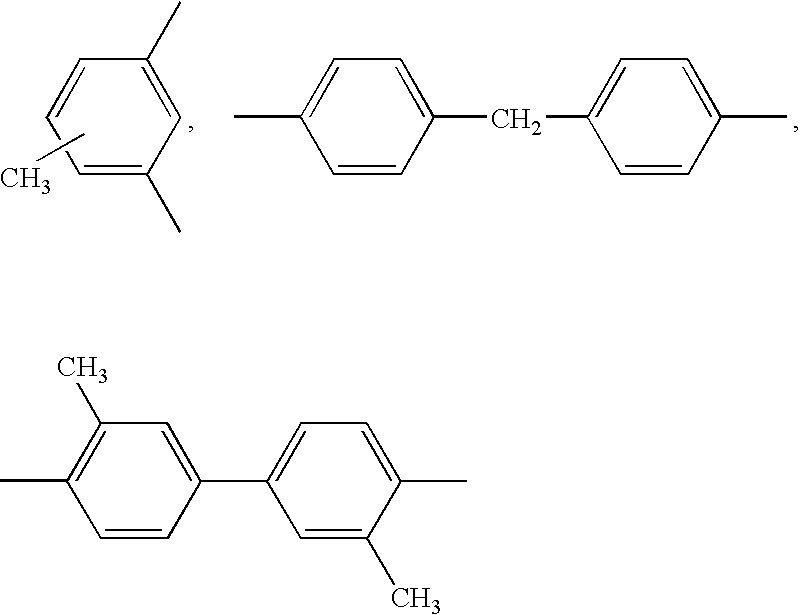

Method used

Image

Examples

example 1

[0034] The present invention will now be explained with reference to the following Examples and Comparative Examples.

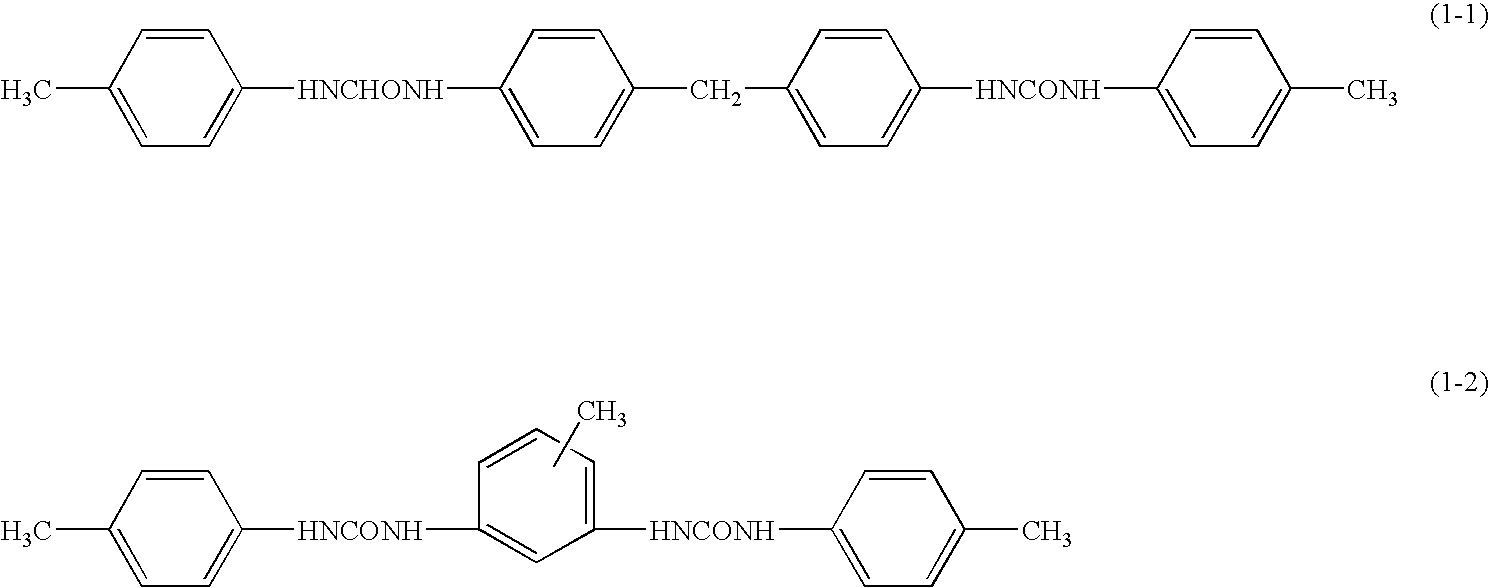

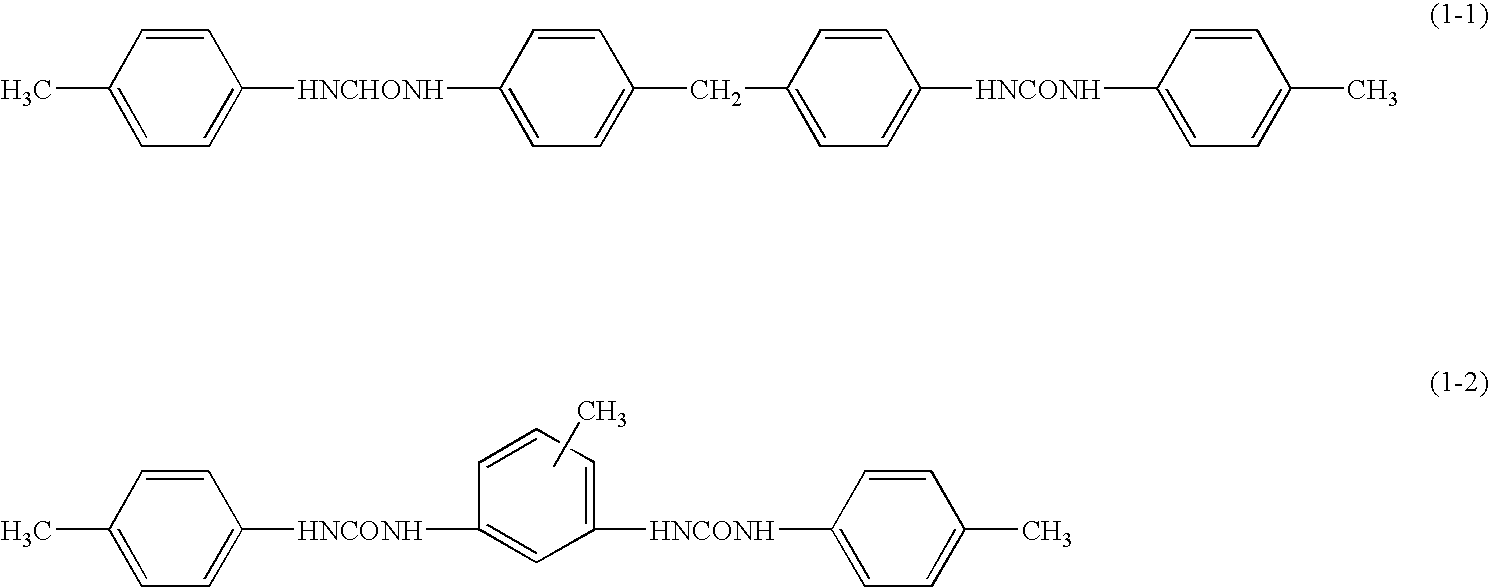

[0035] Grease compositions according to Examples 1 to 4 and Comparative Examples 1 and 2 were independently prepared in such a manner that a thickener and an organic molybdenum compound were added to a base oil as shown in Table 1, and the resultant mixture was kneaded using a three-roll mill. The numerical values in Table 1 indicate the contents (%) in the composition. Examples 1 to 4 and Comparative Example 2 employed an aromatic urea compound represented by the previously mentioned formula (1-1) as the thickener. In each composition, an antioxidant and a rust preventive were incorporated as auxiliary components in amounts of 3% by mass and 2% by mass, respectively. The consistency of each grease composition was measured in accordance with JIS K2220. All the grease compositions were adjusted to have a consistency of 300.

TABLE 1Comp.Comp.Ex. 1Ex. 2Ex. 3Ex. 4Ex. 1E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| total mass | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com