Spacer grid spring for increasing the conformal contact area with fuel rod

一种定位格架、燃料棒的技术,应用在燃料元件的组装、反应堆燃料元件、核能发电等方向,能够解决加速微振磨损等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

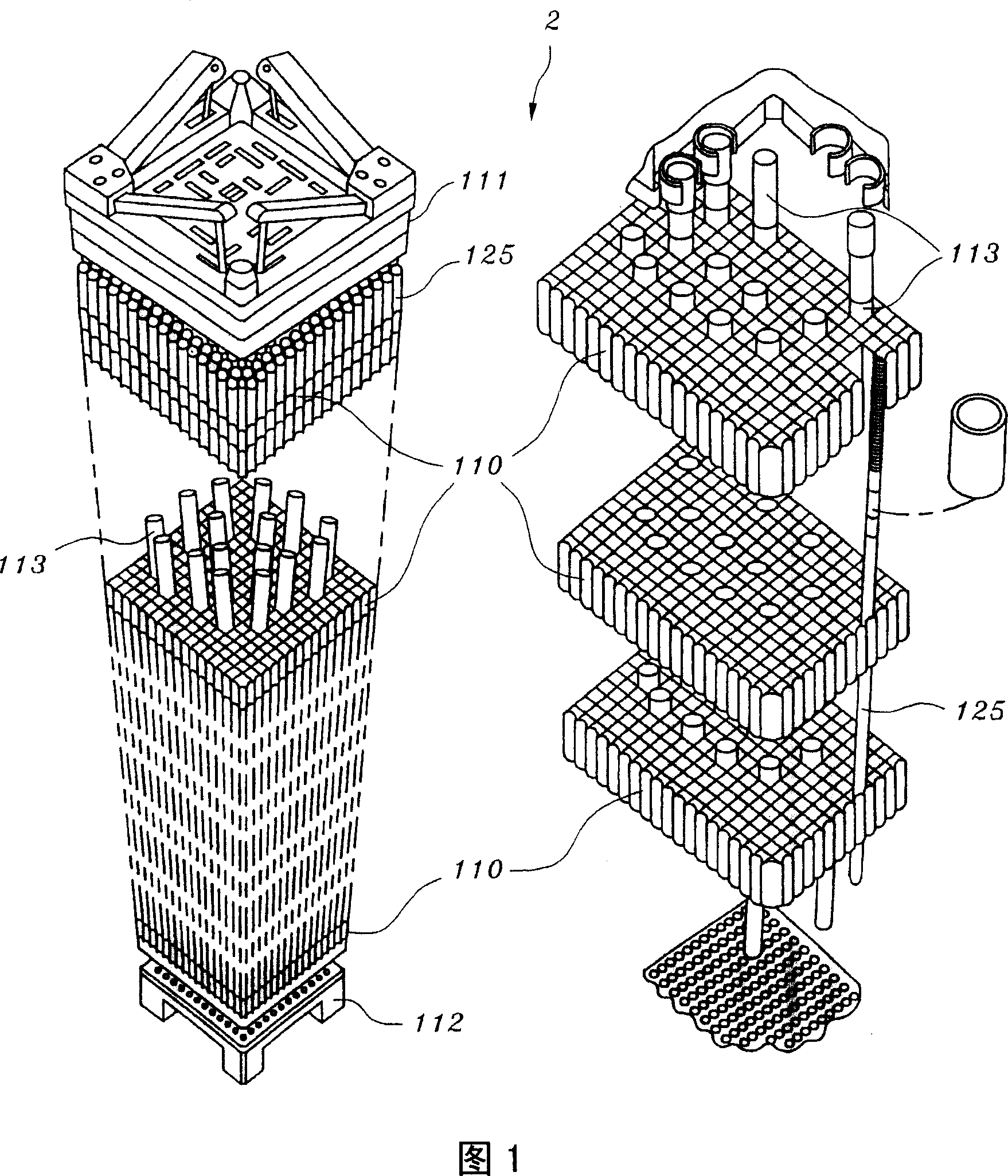

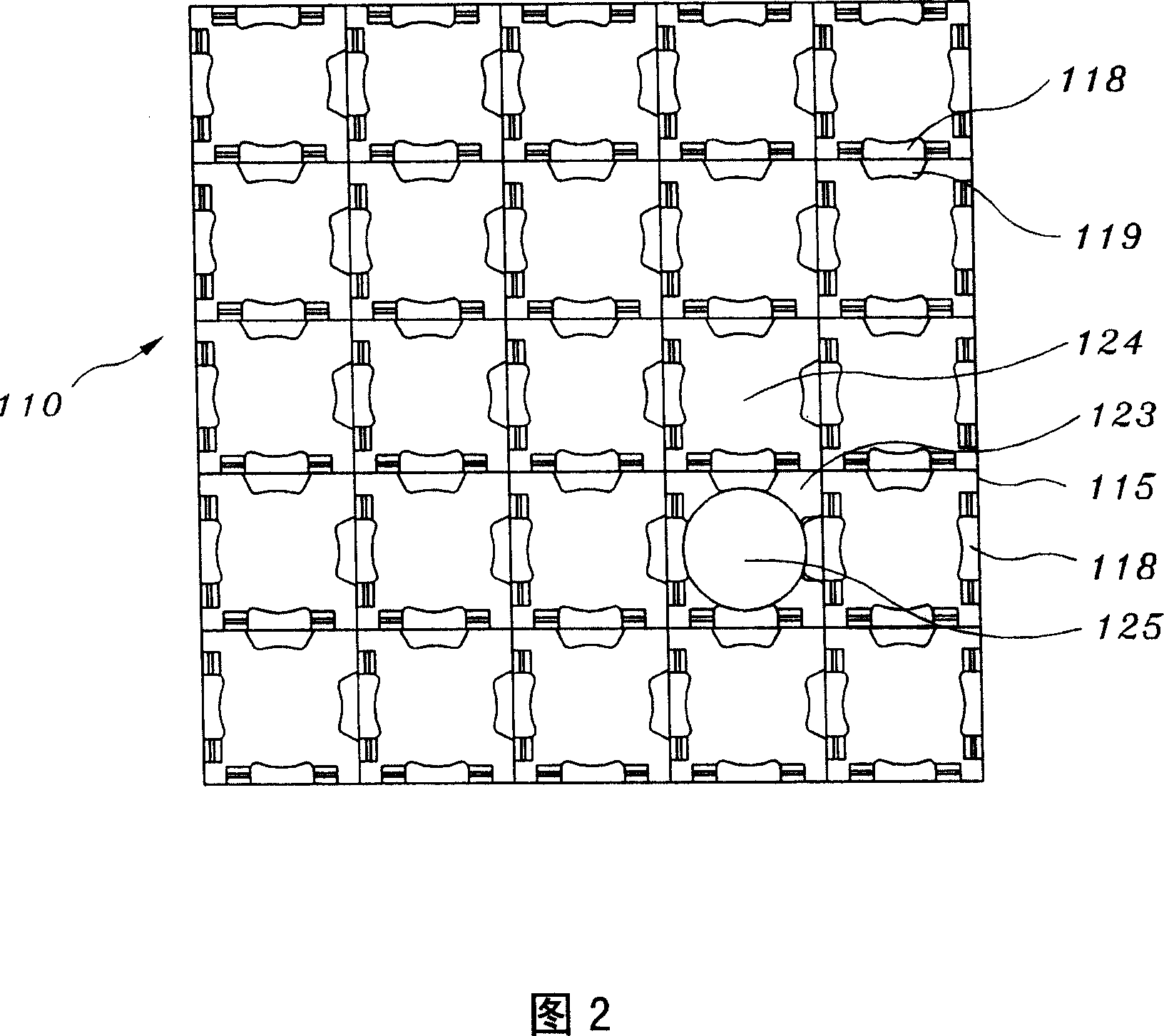

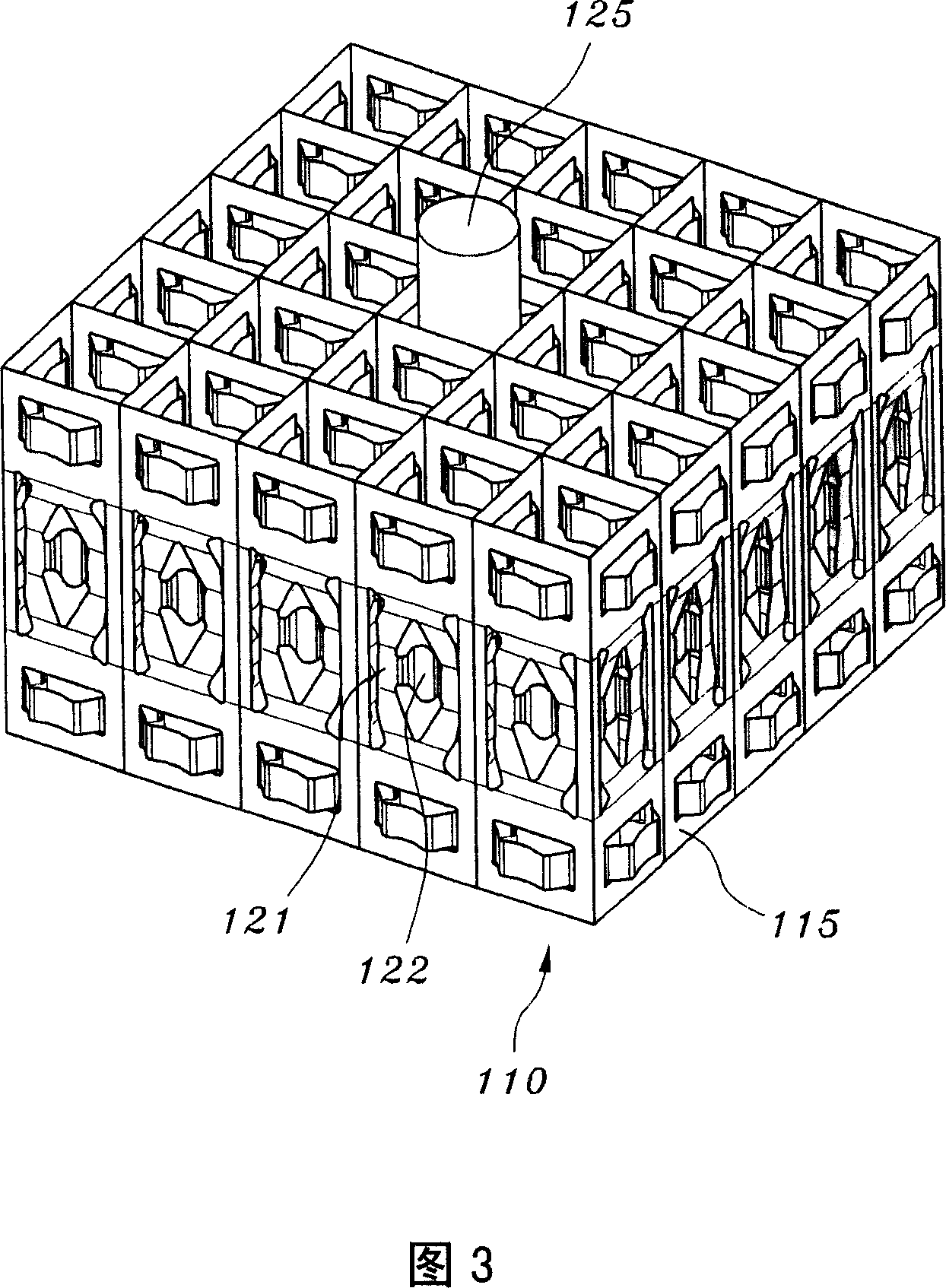

[0043] Reference will now be made in more detail to exemplary embodiments of the present invention, which are illustrated in the accompanying drawings. Whenever possible, the same reference numerals will be used to indicate the same or similar parts throughout the drawings and the description.

[0044] Fig. 6 is a perspective view illustrating a grid strip having a positioning grid spring that increases a conformal contact area with a nuclear fuel rod according to an embodiment of the present invention. Fig. 7 is a front view illustrating a grid strip with a grid spring according to an embodiment of the present invention, wherein the grid spring increases the conformal contact area with the nuclear fuel rod. Fig. 8 is a plan view illustrating a grid strip having a grid spring according to an embodiment of the present invention, wherein the grid spring increases a conformal contact area with a nuclear fuel rod. Figure 9 is a perspective view schematically illustrating a unit of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com