Apparatus for real time observation and recording of fretting wear

A technology of fretting friction and real-time observation, which is applied in the direction of testing wear resistance, etc., can solve the problems of inability to provide more accurate test basis for mechanical design and maintenance, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

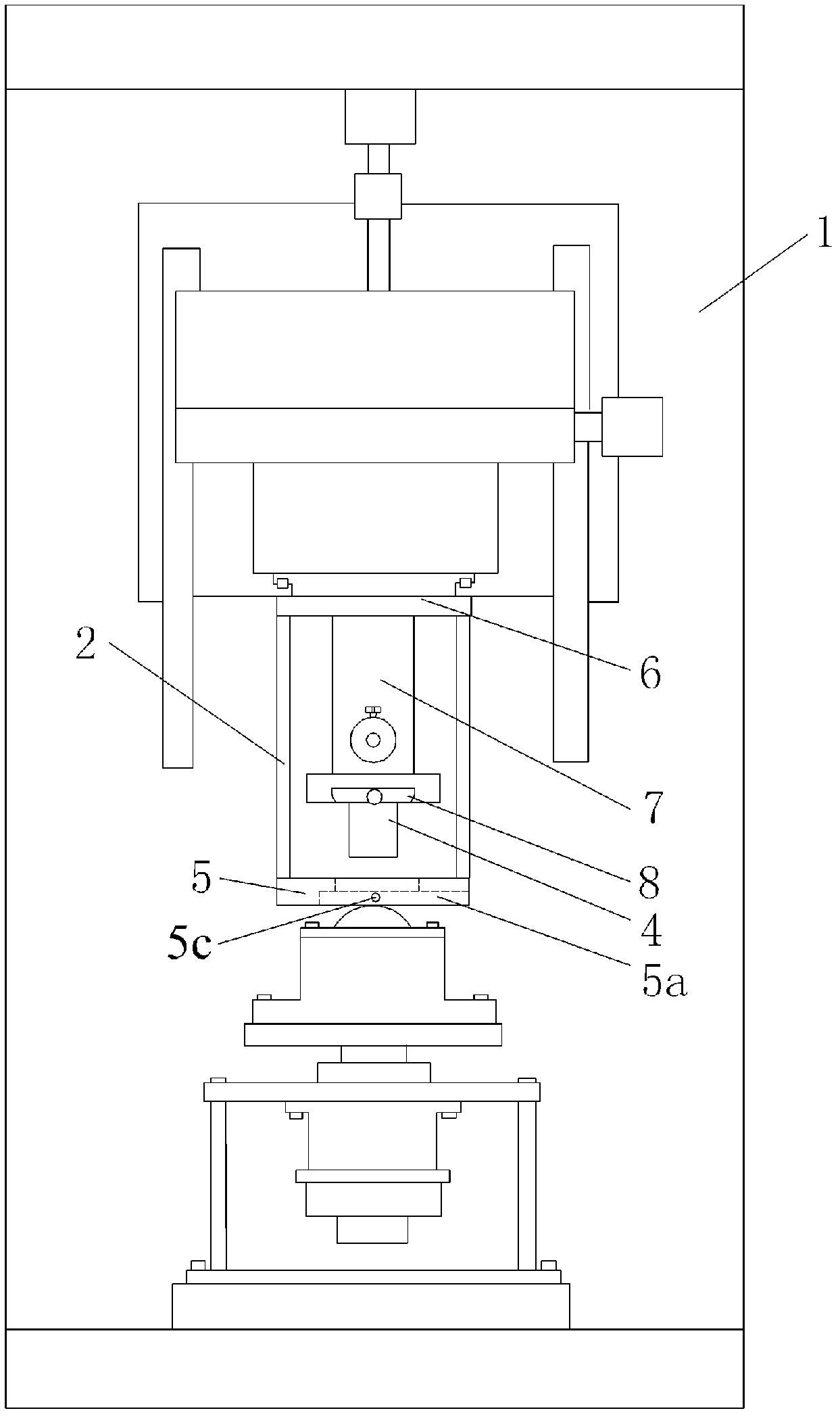

[0022] figure 1 It is shown that a specific implementation of the present invention is a device for real-time observation and recording of fretting friction and wear, and its composition is:

[0023] The top plate 6 of the frame 2 of the device is screwed into the threaded connection hole of the plane sample fixture of the fretting friction test bench 1;

[0024] The upper end of the lens barrel 7 in the frame 2 is fixedly connected with the top plate 6, the lower end of the lens barrel 7 is connected with the magnifying glass 4, the inner cavity of the lens barrel 7 is provided with a downward light source, and the inner cavity of the lens barrel 7 is also provided There is a camera; the camera is electrically connected to the computer via a cable.

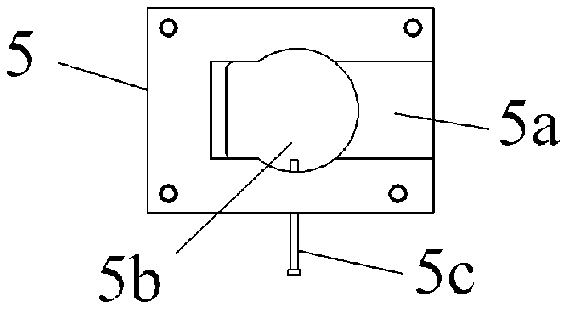

[0025] The bottom surface of the bottom plate 5 of the frame is provided with a clamping groove 5a for clamping a flat sample, and the bottom plate 5 directly under the magnifying glass 4 is provided with a through hole 5b penetrating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com