Shield tunnel T-shaped seam dynamic slab staggering water pressure resistance simulation test device and method

A technology for shield tunneling and simulation tests, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve social economic and people's personal safety threats, poor reliability of test test data, and affect tunnel safety To achieve the effect of simple and convenient adjustment and change, accurate and reliable construction and maintenance, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

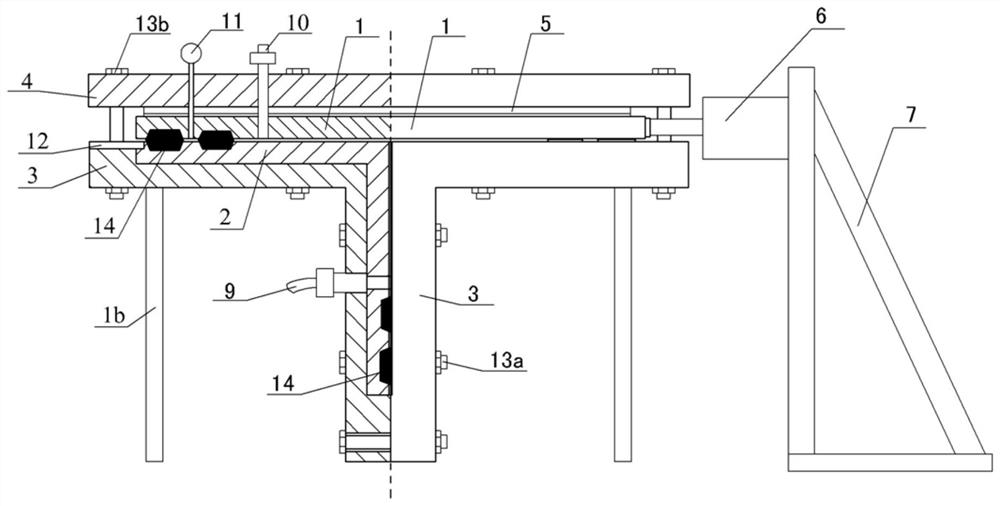

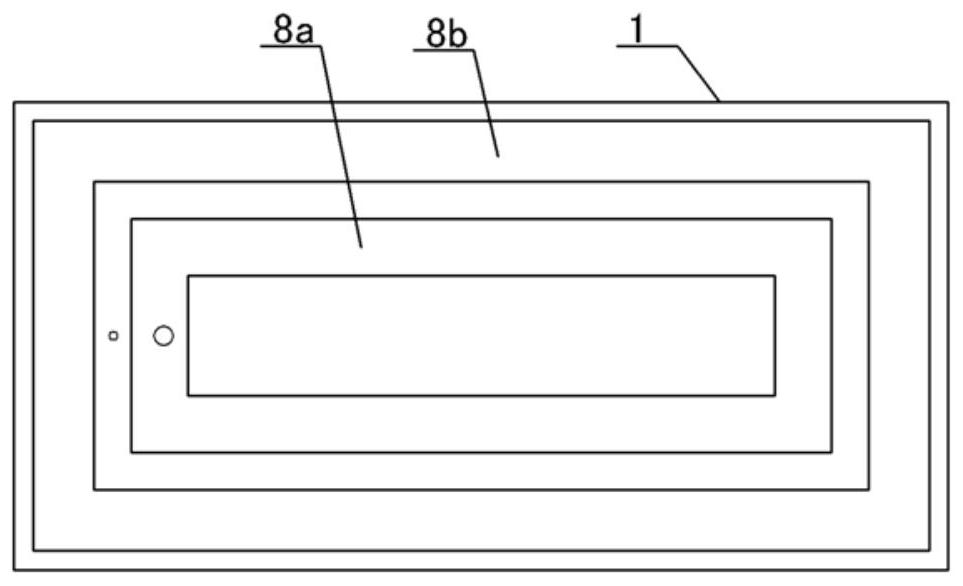

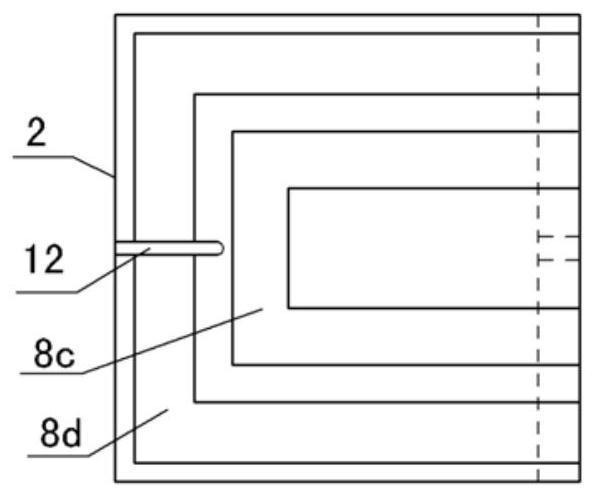

[0036] Figure 1-4 It shows that a specific embodiment of the present invention is a simulation test device for dynamic staggered water pressure resistance of a "T"-shaped joint in a shield tunnel, including a flat plate 1, two right-angled plates 2 below the flat plate 1, and a right-angled plate 2 The outer surface of the vertical plate and the outer surface of the horizontal plate form a "┓" type working surface through; The working surfaces of the vertical plates of the two right-angle plates 2 fit together to form a "T"-shaped seam; and the working surface of the plate 1 is provided with a plane annular groove, and the "┓"-shaped working surface of the right-angle plate 2 is provided with a folded ring The groove, the plane annular groove and the folded surface annular groove are all embedded with a gasket 14; it is characterized in that:

[0037] The right-angle plate 2 is embedded in the groove of the right-angle plate shell 3; the edges of the vertical shells of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com