Device for testing tangential stiffness property of joint surface

A technology of tangential stiffness and joint surface, applied in the direction of applying stable tension/pressure to test material strength, etc., to achieve the effects of easy control of parameters, simple machining, and strong versatility of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the working principle and the structural drawings.

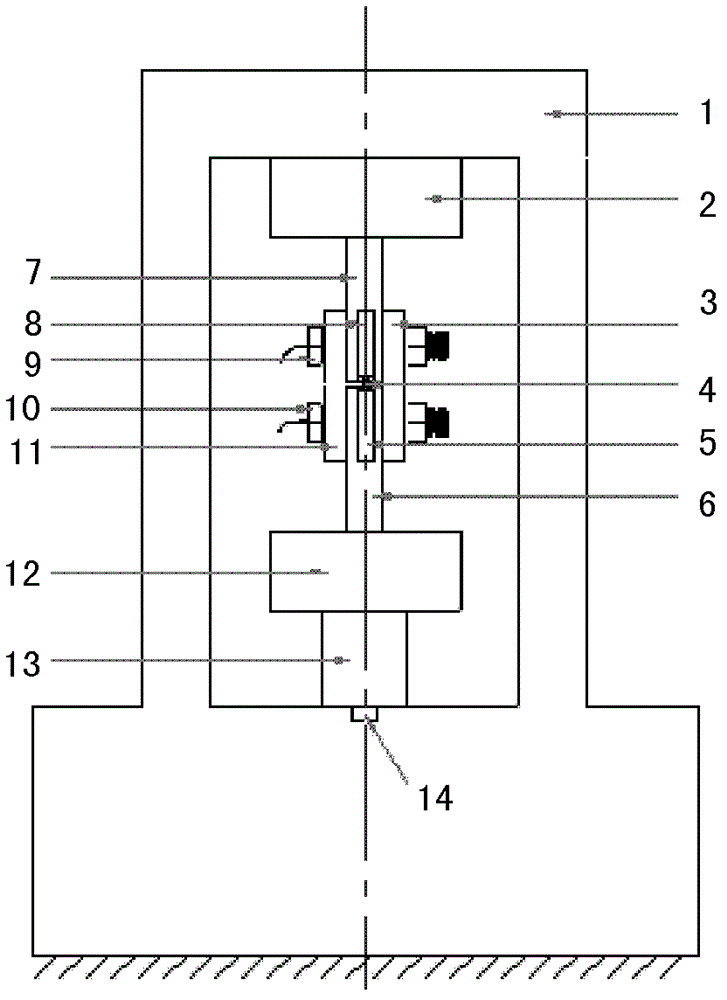

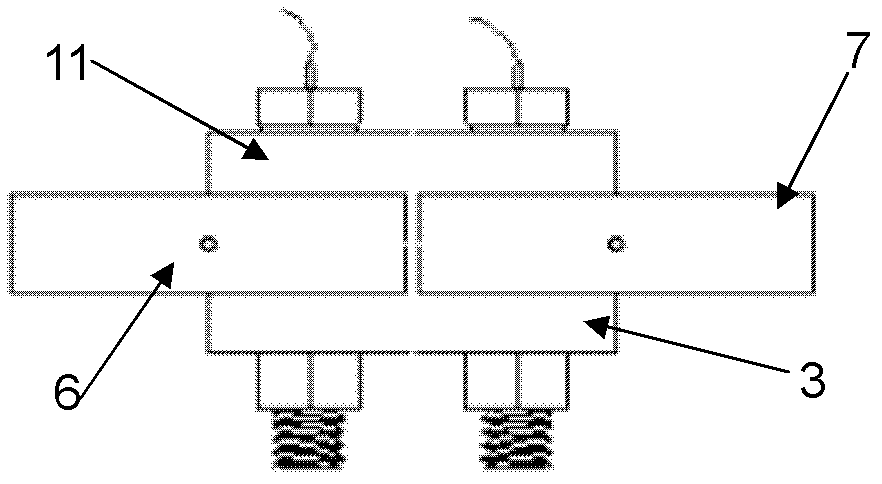

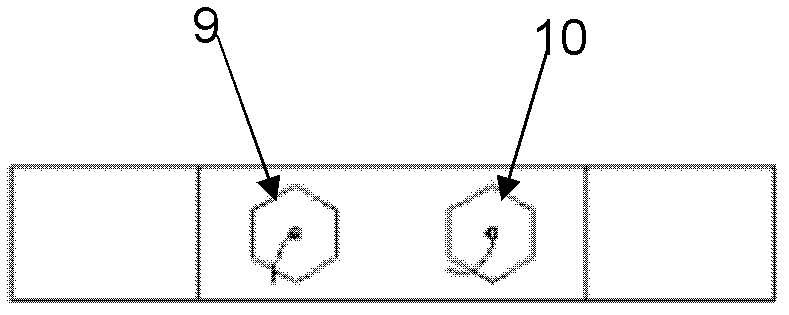

[0039] figure 1 It is a diagram of an experimental device for testing the tangential stiffness characteristics of a joint surface, which is mainly composed of an experimental loading device 1 with a force sensor 14 and a tangential experimental assembly; it is characterized in that the upper test piece 7 and the lower test piece 6 are docked, and the interface is There is a gap, the pressing plate 3 and the pressing plate 11 are respectively placed on the two surfaces perpendicular to the butt surface of the test piece, connected and fixed by two high-strength bolts 9 and 10 to form a tangential experimental assembly, and the high-strength bolts 9 and 10 are about the upper and lower The interface gap of the lower test piece is symmetrical; brackets 8 and 5 are arranged on both sides of the interface gap to install the eddy current dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com