Construction method of one-dimensional finite element model of curved steel-concrete combined box girder

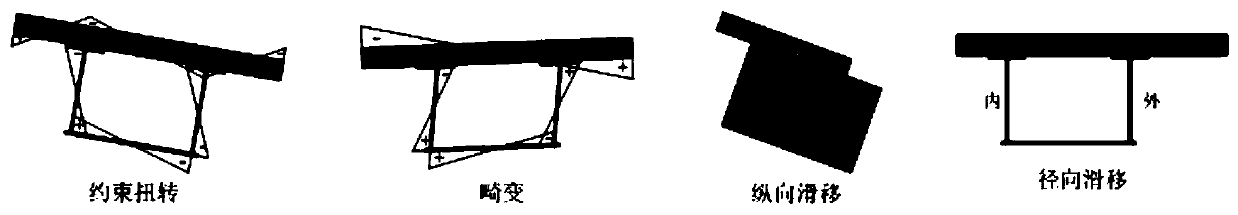

A construction method and technology of combination boxes, which are applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as constraint torsion and distortion effects that cannot be ignored, and bidirectional interface slip of curved composite beams not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] The present invention will be described in further detail below in conjunction with the accompanying drawings.

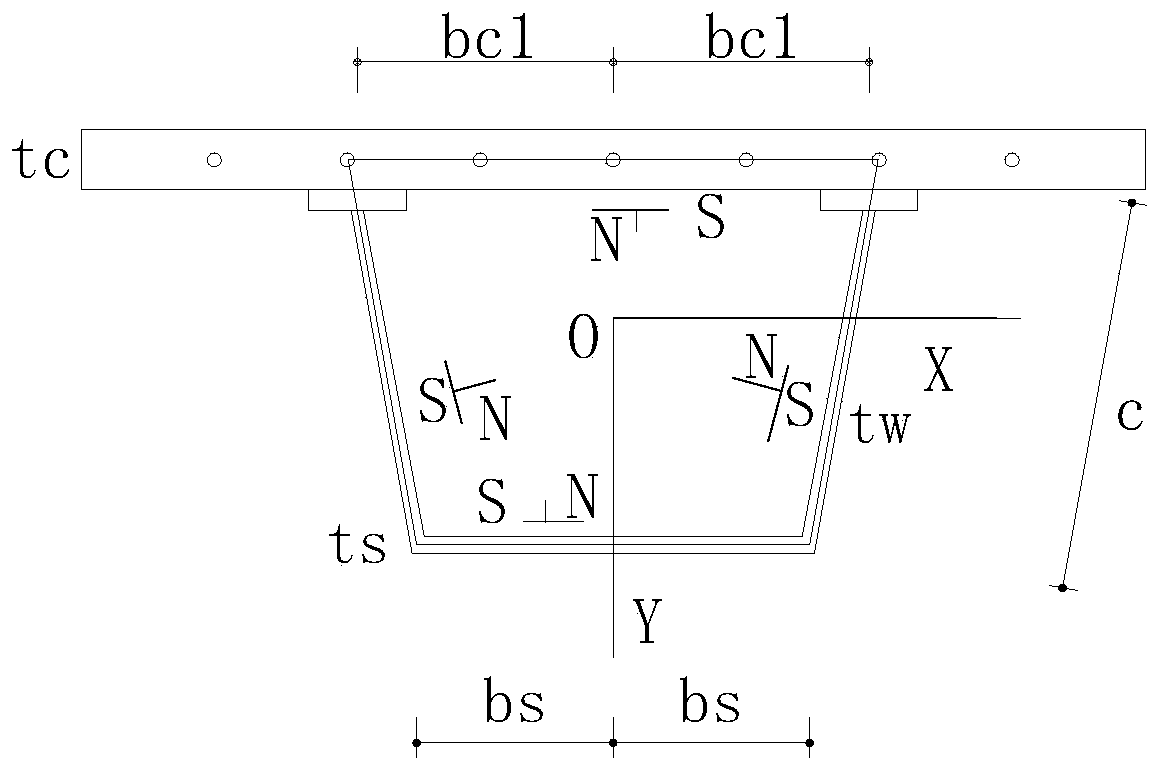

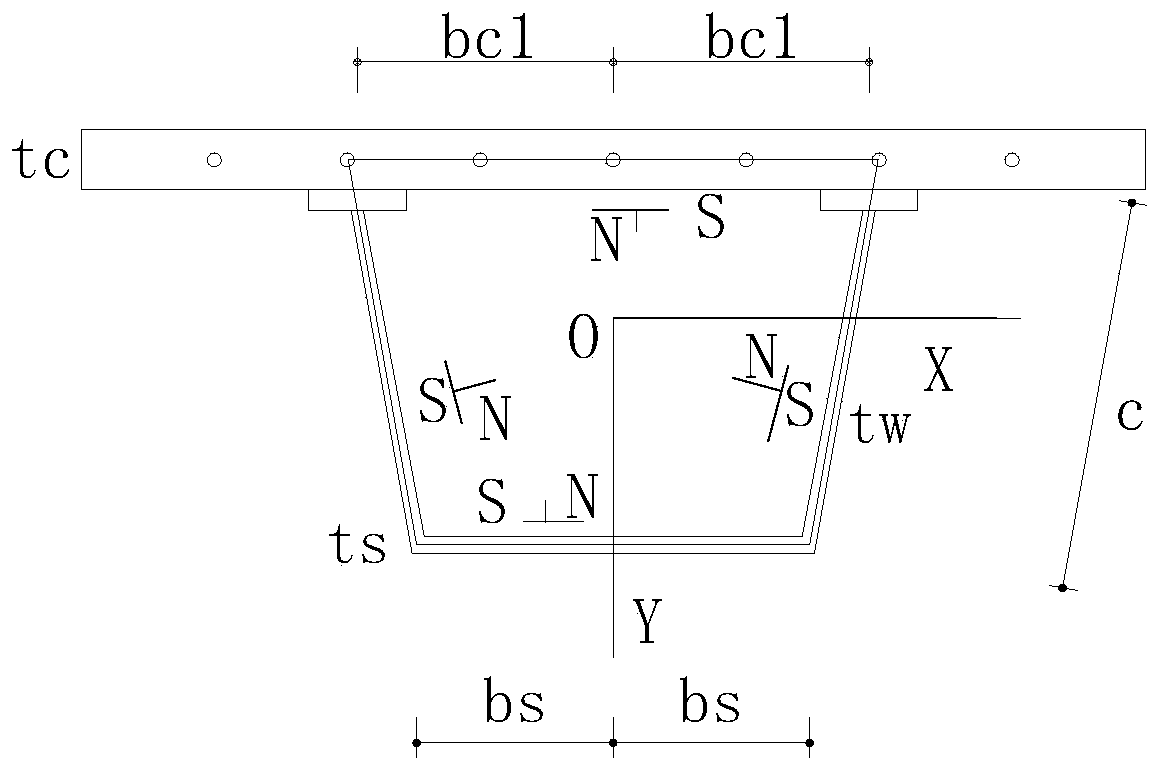

[0137] Such as figure 1 with 2 As shown, the construction method of the curved steel-concrete composite box girder one-dimensional finite element model of the present invention comprises the following steps:

[0138] 1 Make basic assumptions:

[0139] (1) The concrete slab has a rectangular cross-section and has the same curvature as the steel beam in the undeformed structure;

[0140] (2) The vertical displacement of the concrete slab and steel beam is always the same;

[0141] (3) The radius of curvature remains constant along the length of the beam;

[0142] (4) The shear connection between the steel beam and the concrete slab is flexible in both tangential and radial directions;

[0143] (5) The section size of the box girder is much smaller than the span, that is, the change of the radius of curvature in the beam width direction is ignored;

[0144...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com