Sole structure of crawler-type bionic wall-climbing robot and motion method thereof

A wall-climbing robot and crawler-type technology, applied in the field of bionic robots, can solve problems such as inability to adjust adaptively, fixed mechanical properties, etc., and achieve the effect of solving internal redundant forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

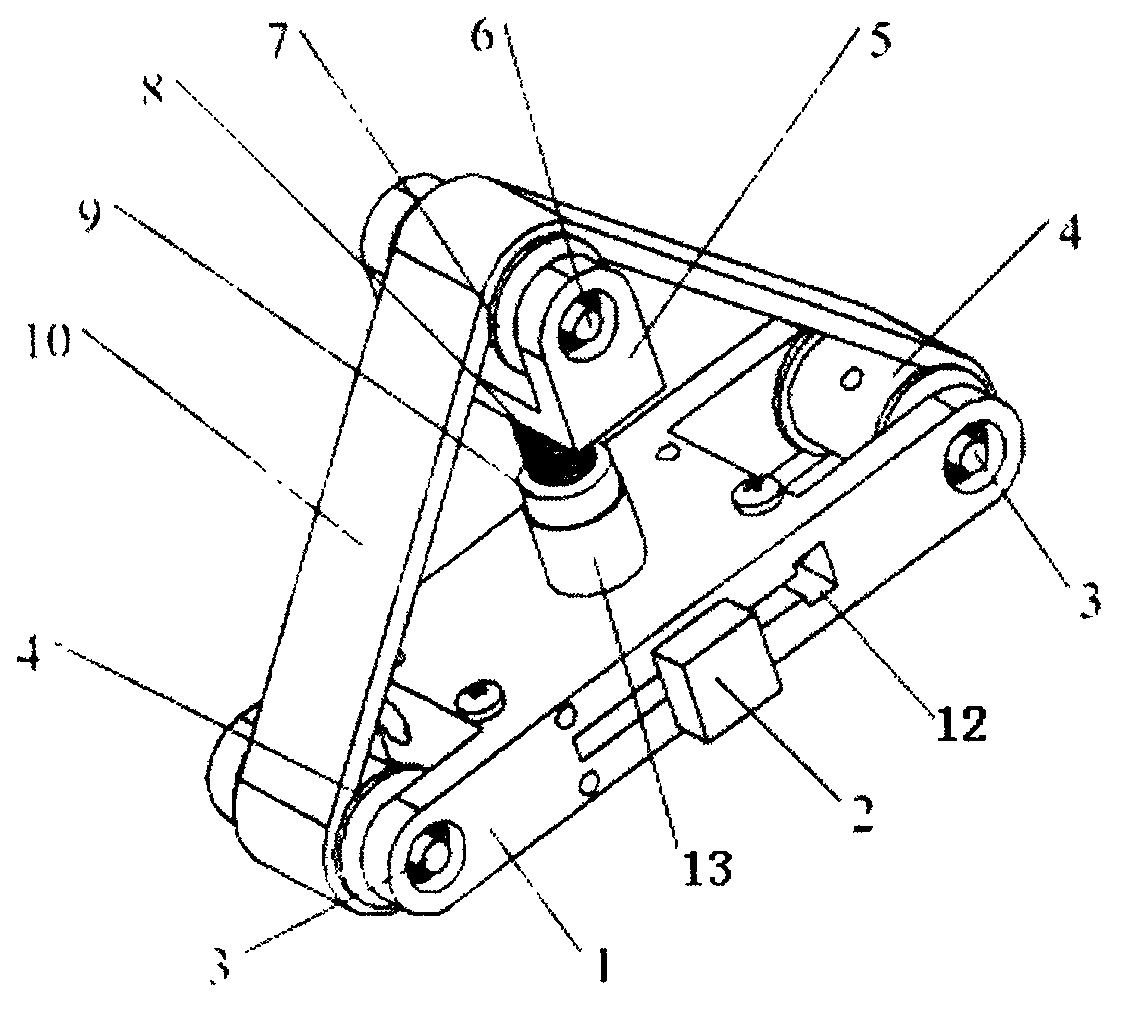

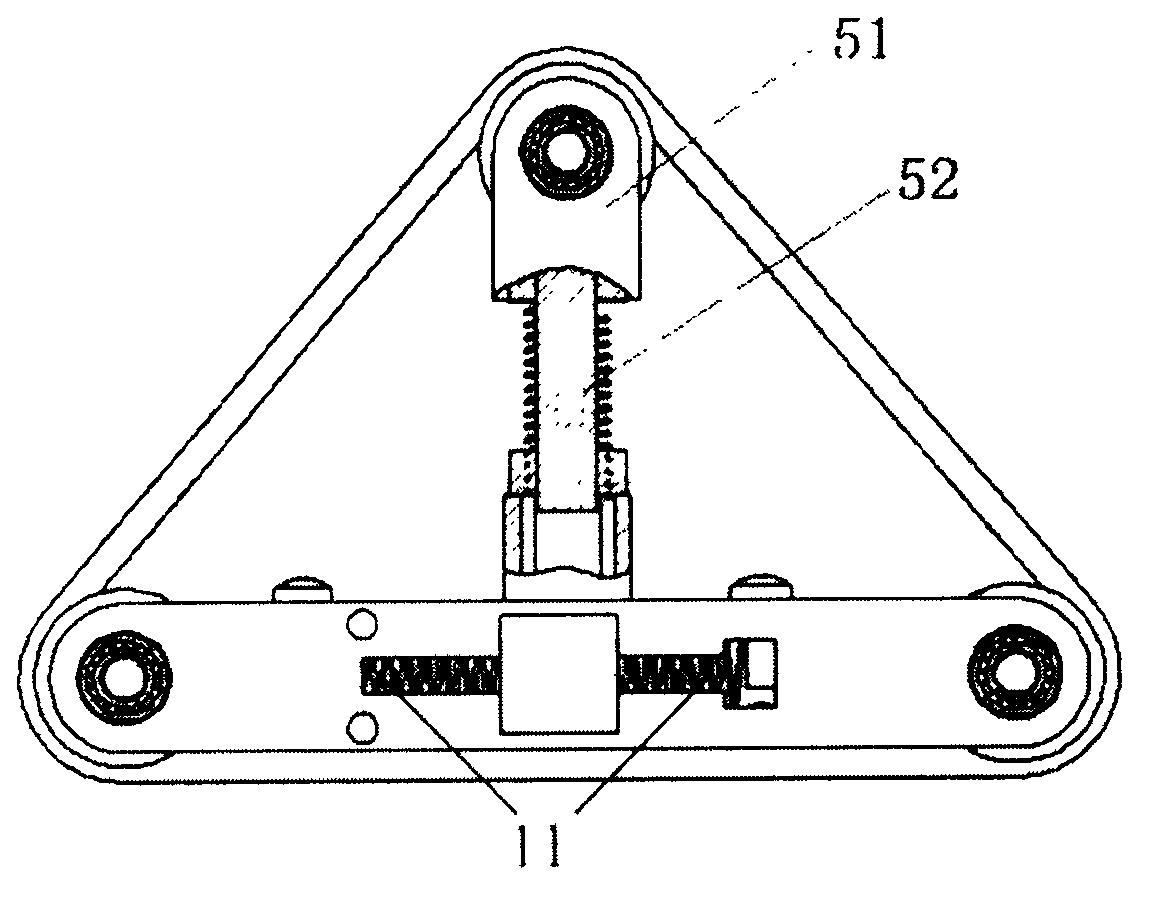

[0040] like Figure 1a and Figure 1bAs shown, a foot structure of a crawler-type bionic wall-climbing robot includes a fuselage frame 1, a rolling wheel 4, a tensioning mechanism, and an adhesive crawler 10. The rolling wheel 4 is installed on the fuselage frame through a rolling wheel shaft 3 1 at both ends, the tensioning mechanism includes a tensioning wheel frame 5, a tensioning spring 8, a miniature force sensor 9, a tensioning wheel 7, and a sleeve 13, the sleeve 1 is provided on the upper surface of the fuselage frame 1 , the upper surface of the sleeve 13 is provided with the miniature force sensor 9, the tensioning wheel frame 5 includes a shaft extension 52 and a mounting end 51, and the lower end of the shaft extension 52 passes through the miniature force sensor 9 and the sleeve 13. A tensioning spring 8 is sleeved on the shaft extension 52, and the tensioning spring 8 is arranged between the miniature force sensor 9 and the mounting end 51, and the tensioning whe...

Embodiment 2

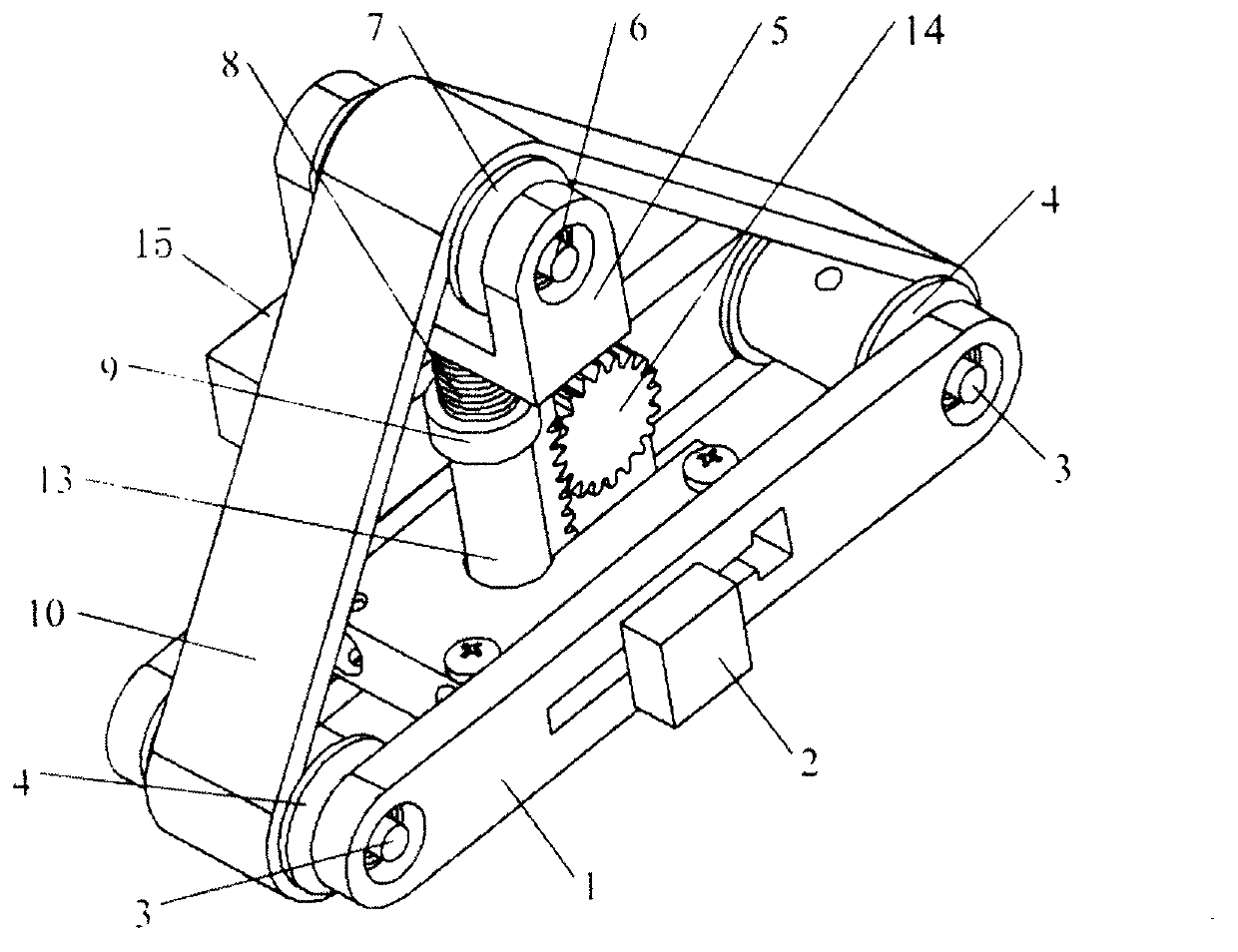

[0045] like Figure 2a , Figure 2b and Figure 2c As shown, the sleeve 13 is a lifting sleeve arranged on the upper surface of the fuselage frame 1, the outer side of the lifting sleeve is provided with a rack, and the fuselage frame 1 is provided with a tensioning The driving gear 14 of the motor 15 engages the rack of the lifting sleeve and drives the lifting sleeve to rise and fall.

[0046] like Figure 3a , Figure 3b , Figure 3c Shown is the movement method of the second embodiment of the foot sole structure of the anti-living wall-climbing robot traveling on a flat surface. like Figure 3a As shown, the robot body outputs motion commands of rotation and translation in the x-y plane to the sole of the foot by controlling the lateral movable member 2 . Through the rotating motion, the connecting line between the two rolling wheels of the sole of the foot and the wall surface forms a certain orientation angle α. With the sole of the foot in the suspended phase, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com