Method for checking gear involute tooth profile error

A technology of tooth profile error and inspection method, applied in the field of transmission gears, can solve the problems of tediousness, inability to implement processing, and inability to meet product requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The present invention is used for the testing method of gear involute tooth form error, and this method comprises the following steps:

[0083] Step 1, measure and calculate the tooth shape coordinate points of the gear under test;

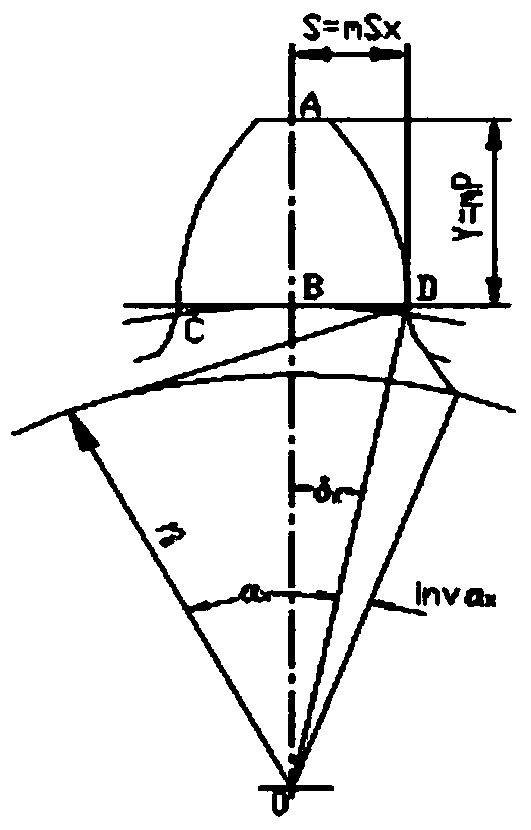

[0084] Step 2, deduce the theoretical involute tooth profile coordinates of the height displacement and tangential displacement bevel gears on the basis of the calculation of the involute tooth profile coordinate points of the original spur gear and straight bevel gear;

[0085] Step 3, the distance between the origin of the tooth shape coordinates of the measured gear in step 1 and the theoretical involute tooth shape tooth top circle coordinates derived in step 2 is the tooth shape error;

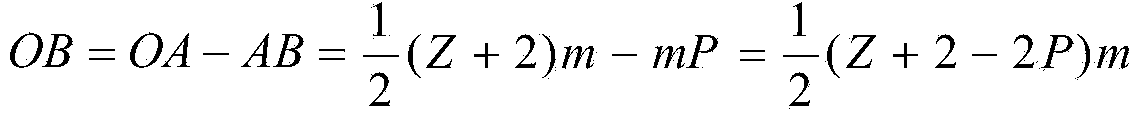

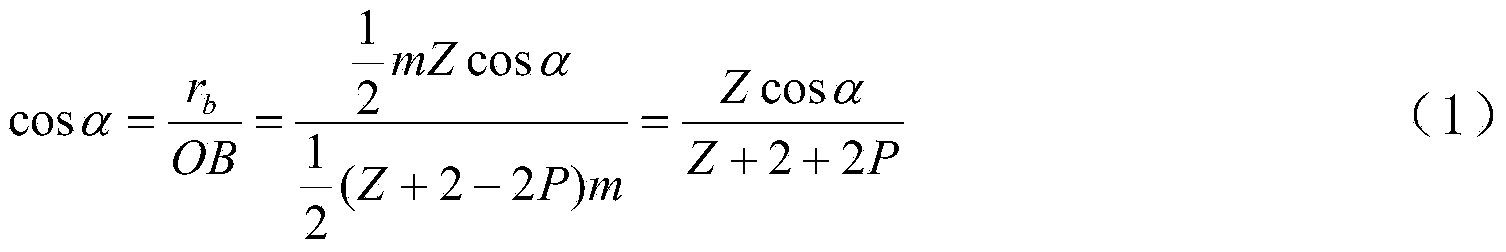

[0086] According to the principle of involute tooth shape and the calculation formula of high-displacement and tangential-displacement bevel gear big-end circular tooth thickness calculation formula, the calculation formula of fixed chord tooth thickne...

Embodiment 2

[0105] The parameters of a product of the company's grade 7 precision spur bevel gear are shown in Table 2:

[0106] Table 2 Parameters of cut straight bevel gear mm

[0107]

[0108] According to the parameters of the cut straight bevel gear in Table 2 in this example, find the coordinates of each point on the gear tooth profile.

[0109] Solution: First calculate the reference pitch circle diameter of the bevel gear:

[0110]

[0111] Find Zy and m when looking up the tooth shape coordinate value table 3 y

[0112] m y =m(1+0.463421x 1 +0.31831x t1 )

[0113] =1[1+0.463421(-0.5)+0.31831(-0.01)]=0.765

[0114] Z y = d y m y = 228.2 0.765 = 298.3

[0115] At this time, the distance from the coordinate origin to the theoretical addendum circle is:

[0116...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com