Power generation system of Atkinson cycle engine

A power generation system, Atkinson's technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of reducing the number of parts, short cruising range, and short life, and achieve the effect of reducing quantity and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

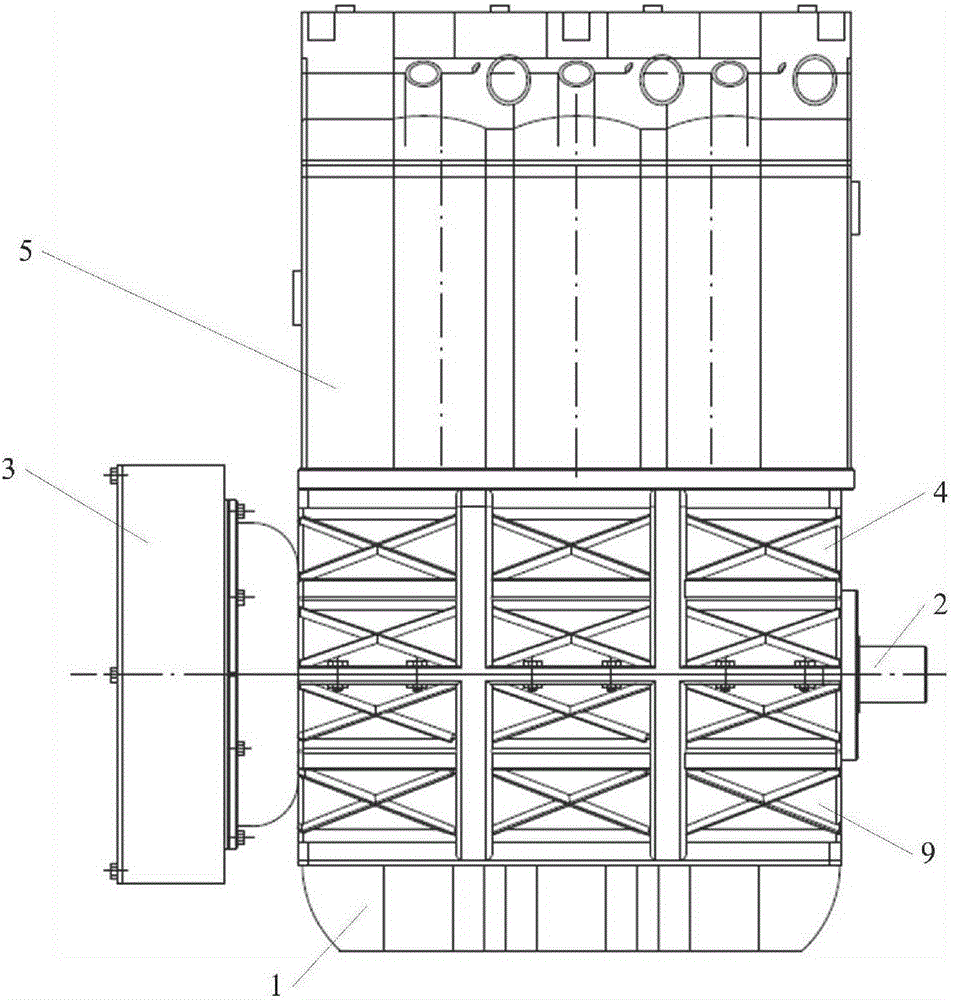

[0023] figure 1 is an external schematic diagram of the power generation system of the Atkinson cycle engine of the present invention;

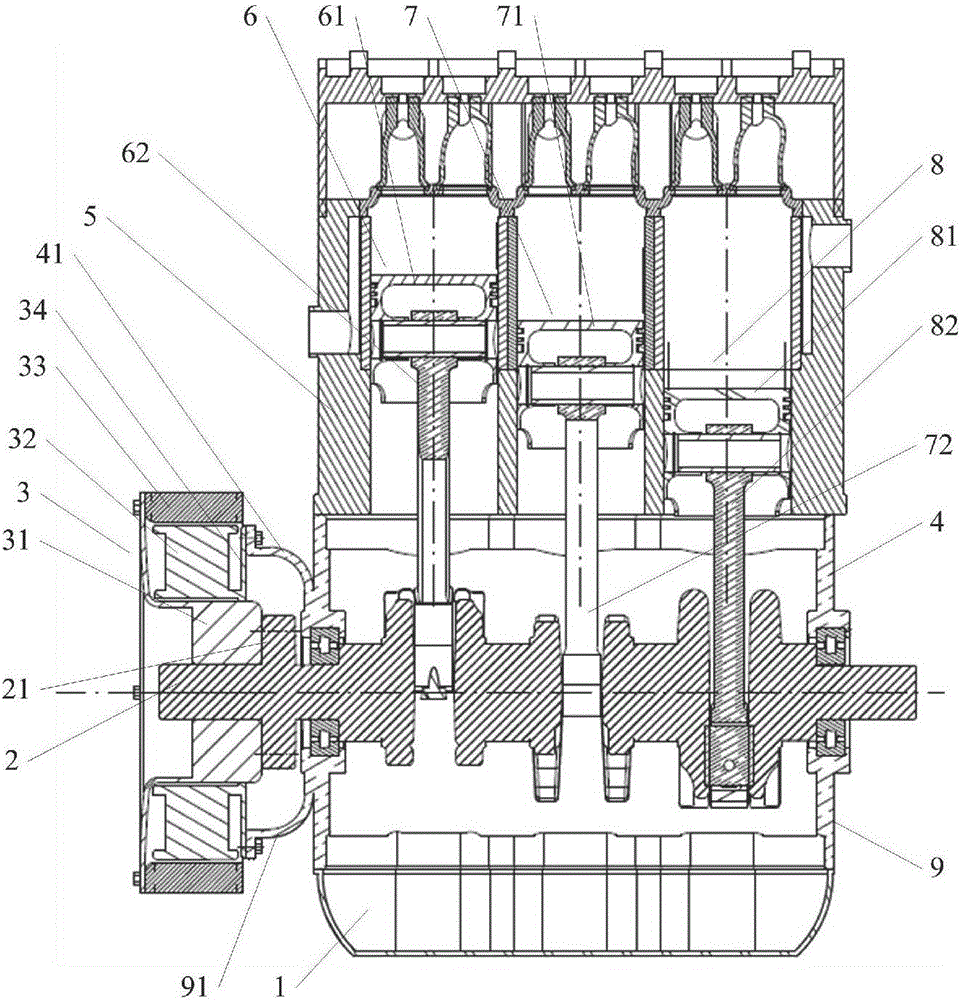

[0024] figure 2 is an internal schematic diagram of the power generation system of the Atkinson cycle engine of the present invention.

[0025] Such as figure 1 , 2 As shown, the Atkinson cycle engine power generation system provided in this embodiment includes an Atkinson cycle engine and an external rotor generator 3 .

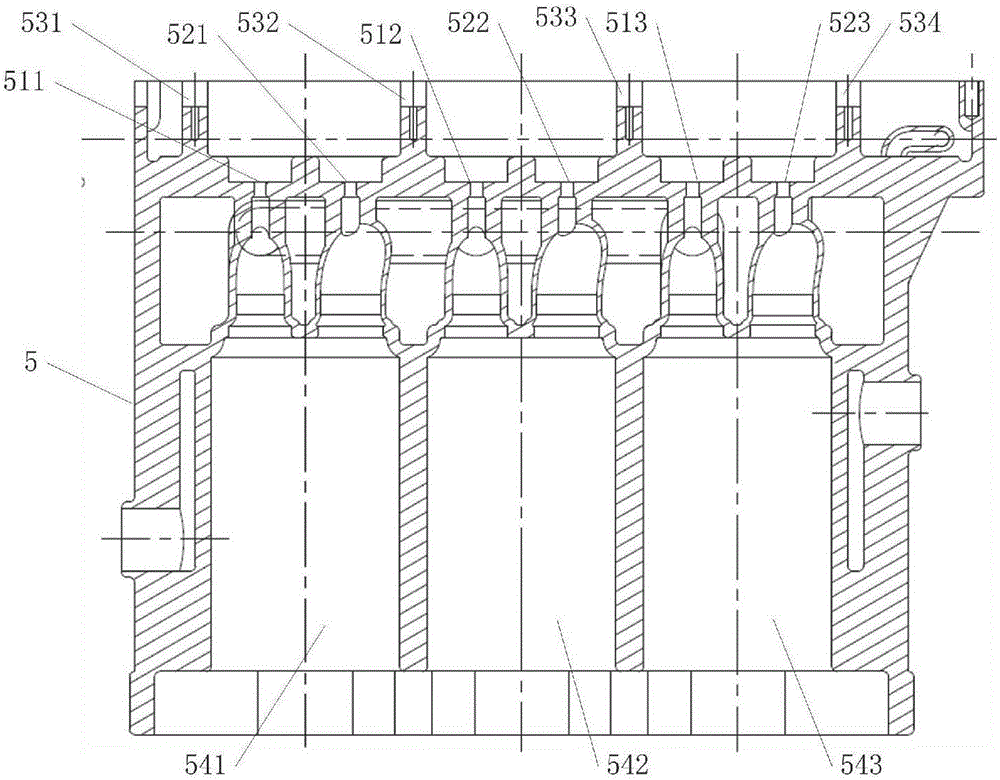

[0026] The Atkinson cycle engine comprises an integrated cylinder block 5 integrally formed with a cylinder block and a cylinder head, three piston linkages 6, 7, 8 arranged in the integration cylinder 5, and a cylinder connected to the three piston linkages. The crankshaft 2, the upper half crankcase 4 and the lower half crankcase 9 connected under the integrated cylinder block 5, and the oil pan 1 installed under the lower half crankcase 9.

[0027] An upper disc support 41 and a lower disc support 91 are provided o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com