Four-stroke reciprocating piston internal combustion engine

A technology of reciprocating piston and internal combustion engine, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problems of limiting the power increase and compression ratio of the internal combustion engine, hindering the intake air volume of the suction stroke, and the complexity of the multi-link mechanism. The effect of improving power, simple structure and sufficient oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

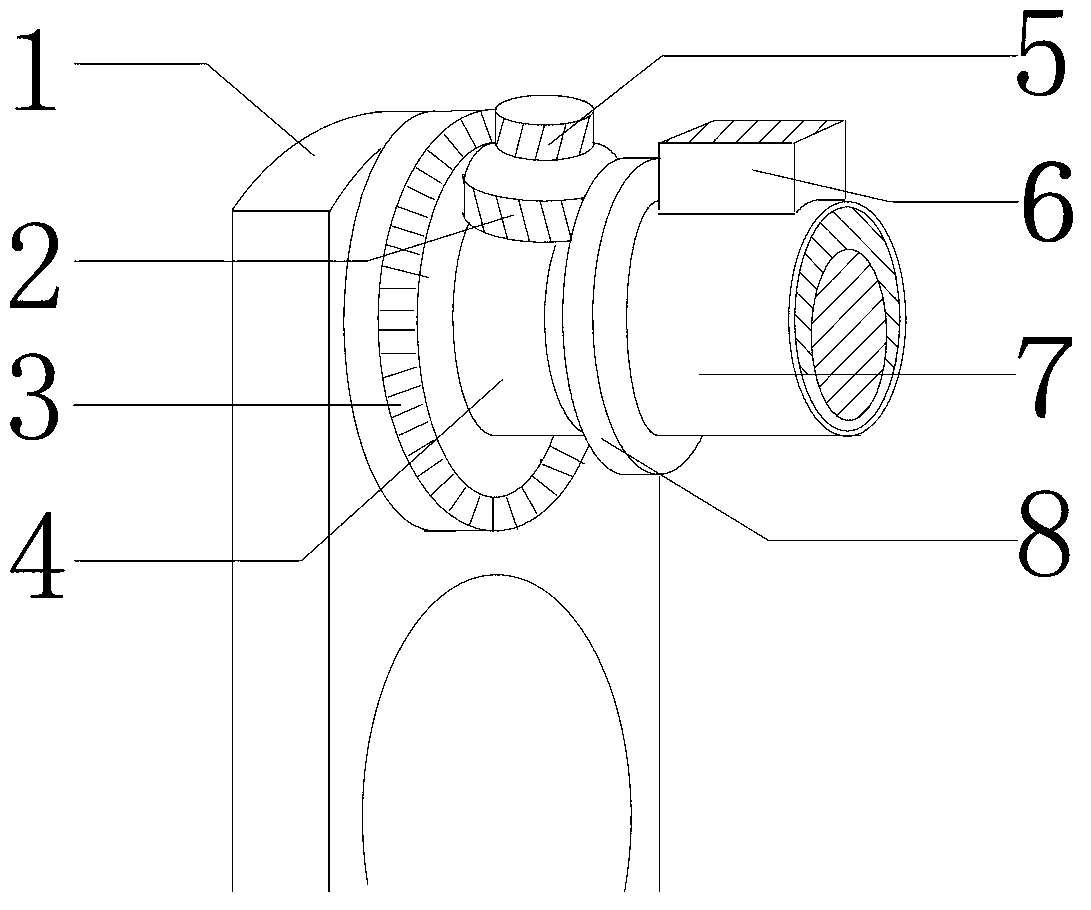

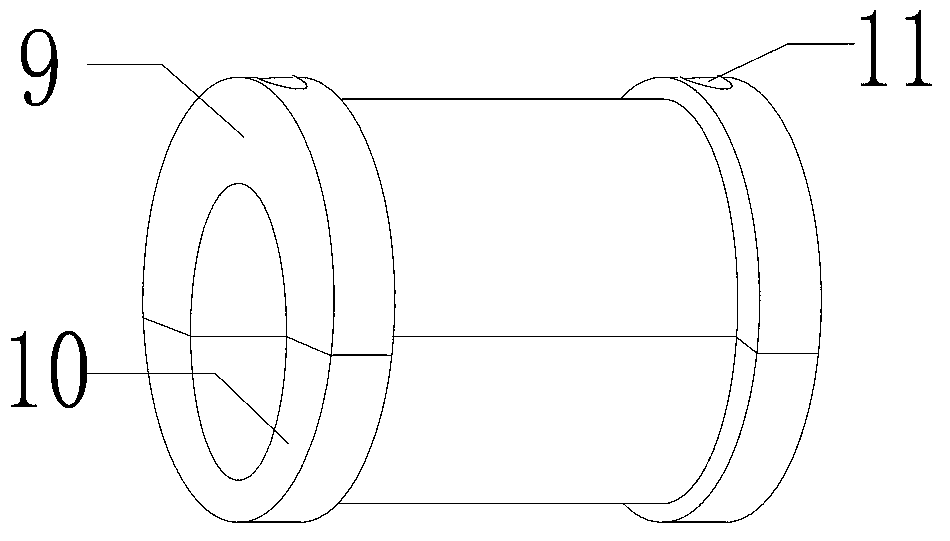

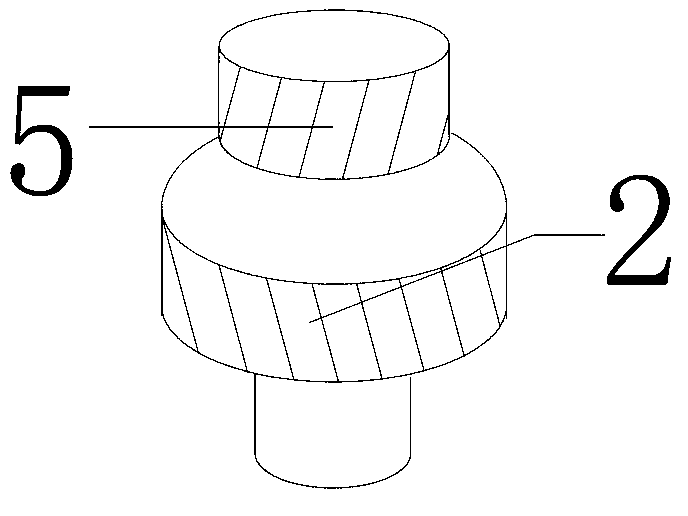

Embodiment 1

[0023] Otto cycle: At the beginning of the suction stroke and the end of the exhaust stroke, the thick edge block 9 of the eccentric shaft 4 is located at the top of the connecting rod big end 7 as Figure 4a As shown, the maximum stroke of the piston reaches the top of the cylinder; at the beginning of the power stroke and the end of the compression stroke, the thick edge block 9 of the eccentric shaft 4 is located at the bottom of the big end of the connecting rod 7 as shown Figure 4c As shown, the stroke of the piston is shortened, and a combustion chamber is formed between the piston and the top of the cylinder. The stroke of the piston in the suction and exhaust strokes is greater than that in the power and compression strokes, that is, the top dead center of the piston is variable. The stop remains unchanged. Compared with the prior art, the internal combustion engine increases the eccentric shaft 4 to extend the stroke of the piston in the intake and exhaust strokes, a...

Embodiment 2

[0027]Atkinson cycle: the eccentric shaft 4 of embodiment 1 is installed by rotating 90 degrees around its axis, and the effect opposite to that of embodiment 1 occurs, the top dead center of the piston is constant, and the bottom dead center is variable. The stroke of the piston in the power stroke and the exhaust stroke becomes longer, the stroke of the piston in the suction stroke and the compression stroke becomes shorter, the expansion ratio of the internal combustion engine is greater than the compression ratio, and it runs with a larger radius of the crank 1 during the power stroke, resulting in Greater torque and improved power. The internal combustion engine realizes the thermal efficiency and fuel economy of the Atkinson cycle, produces power exceeding the Otto cycle, and overcomes the defects of low-speed torque difference, complex multi-link mechanism and high failure rate of the Atkinson cycle internal combustion engine. Because the excessive expansion of the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com