A Method for Realizing the Atkinson Cycle of a Naturally Aspirated Gasoline Engine

An Atkinson, naturally aspirated technology, used in mechanical equipment, engine components, combustion engines, etc., can solve the problems of difficult combustion stability, unstable combustion, low intermediate load thermal efficiency, etc., to reduce the low load misfire rate, Improved combustion stability, enhanced turbulence intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] like Figure 1 to Figure 12 Shown, a kind of naturally aspirated gasoline engine Atkinson cycle realization method of the present invention, the method comprises:

[0033] (1) High-energy ignition coil is adopted, and the ignition energy of the ignition coil is at least 80mJ, which can ensure low-speed, low-load or high EGR rate working conditions, stable combustion, and reduced misfire rate.

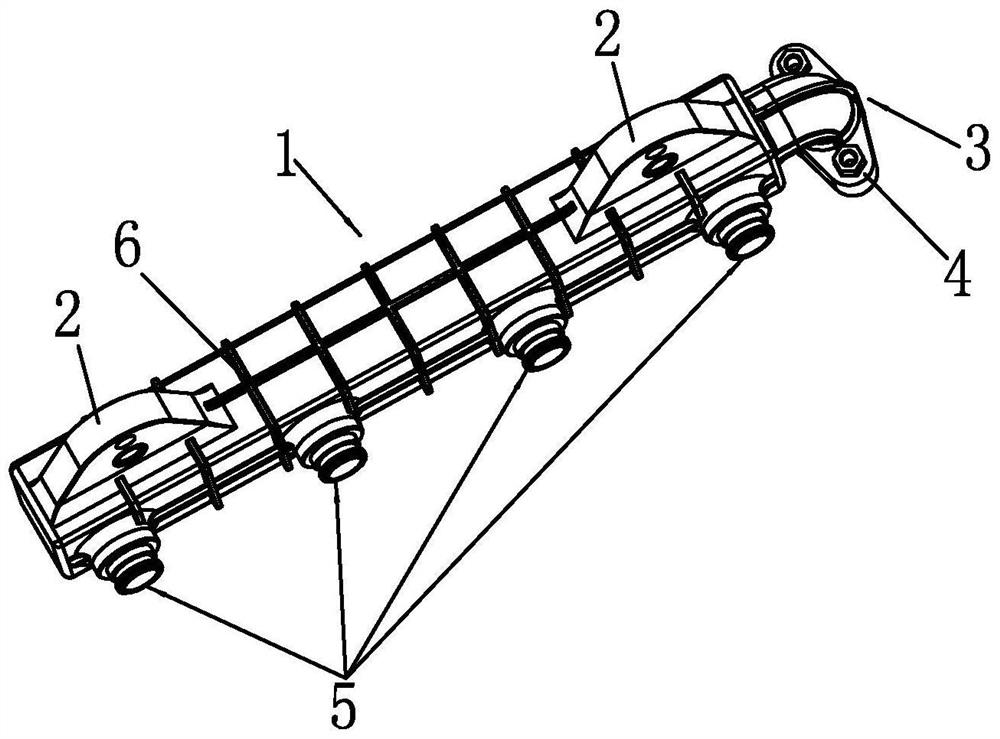

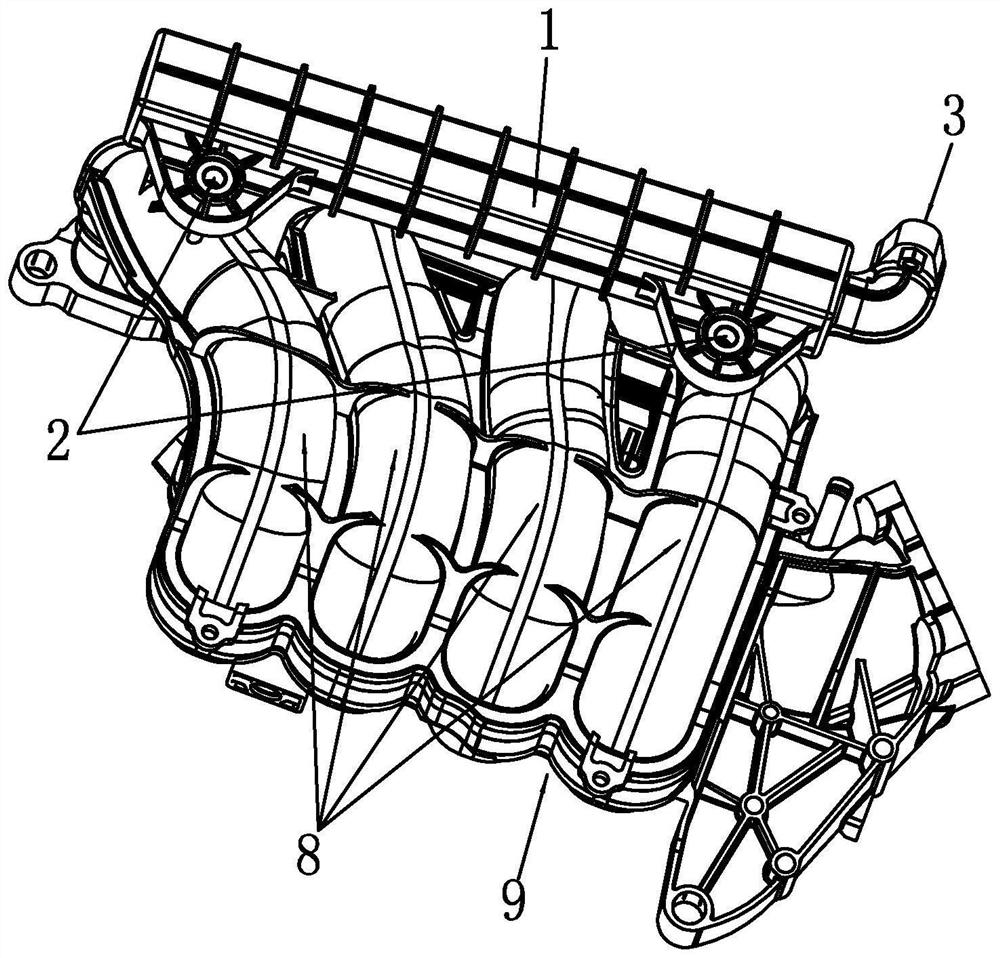

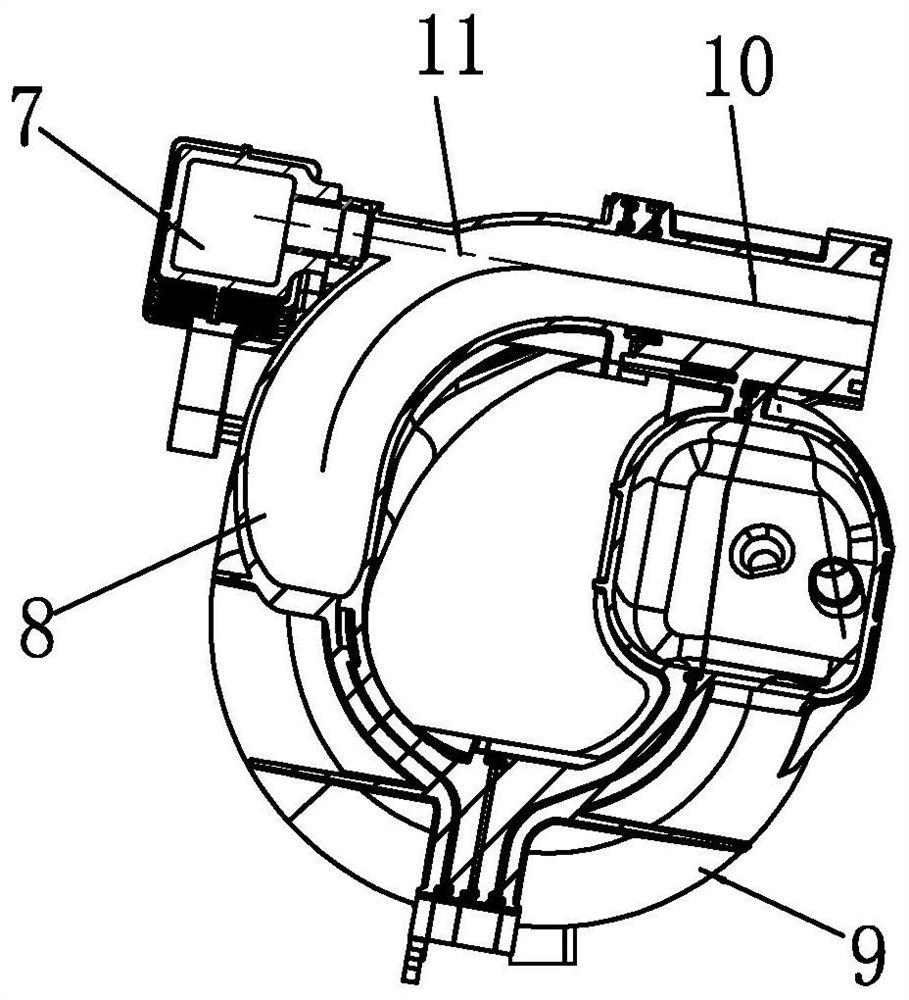

[0034] (2) The EGR stabilizing chamber 1 is integrated on the intake manifold 9, and the EGR system takes the exhaust gas from the outlet of the exhaust manifold 12, and the exhaust gas passes through the EGR pipeline 14, the EGR cooler 16, the EGR valve 15, and the EGR pipeline 14. Entering the EGR plenum chamber 1, the exhaust gas is collected in the EGR plenum chamber 1 and evenly distributed to each branch pipe 8 of the intake manifold 9, such as image 3 , 4 shown; see also figure 1 , 2, the EGR pressure stabilizing chamber 1 includes a stabilizing volume chamber 7, an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com