Atkinson cycle engine assembly with cooled EGR

An engine assembly, Atkinson's technology, applied to engine components, engine cooling, machine/engine, etc., can solve problems such as torque drop, achieve the effects of reducing lateral force, reducing fuel consumption, and optimizing waterway structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the purpose, structure and function of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings.

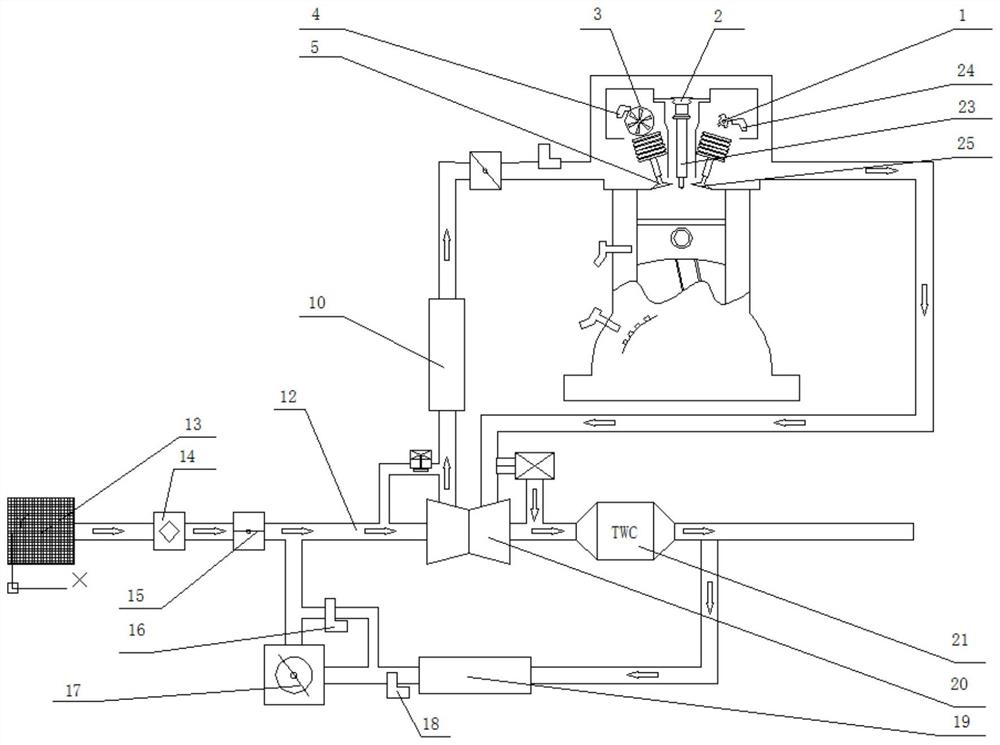

[0031] Engine schematics, such as figure 1 shown.

[0032] Each engine cylinder is equipped with a crank connecting rod mechanism, a gas distribution system, an ignition system, an intake system and an exhaust system;

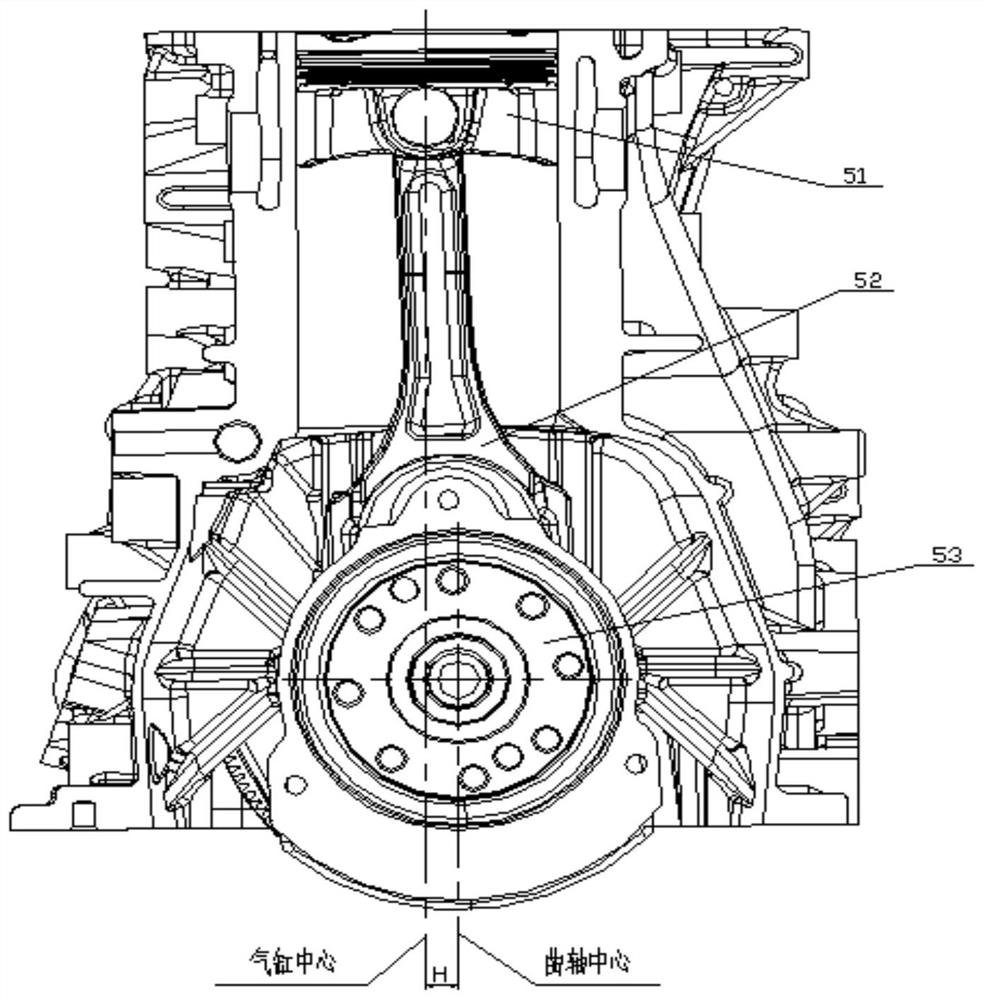

[0033] Such as image 3 As shown, the crank-link mechanism includes crankshaft 53, connecting rod 52, piston 51 and other parts, which are arranged eccentrically. The crankshaft offset technology means that the center of the crankshaft does not intersect with the centerline of the piston, that is, the eccentric distance H between the axis of the piston 51 and the axis of the crankshaft 53 , H≈9~11mm.

[0034] The working cycle of the engine is four-stroke, which includes intake stroke, compression stroke, power stroke and exhaust stroke.

[0035] Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com