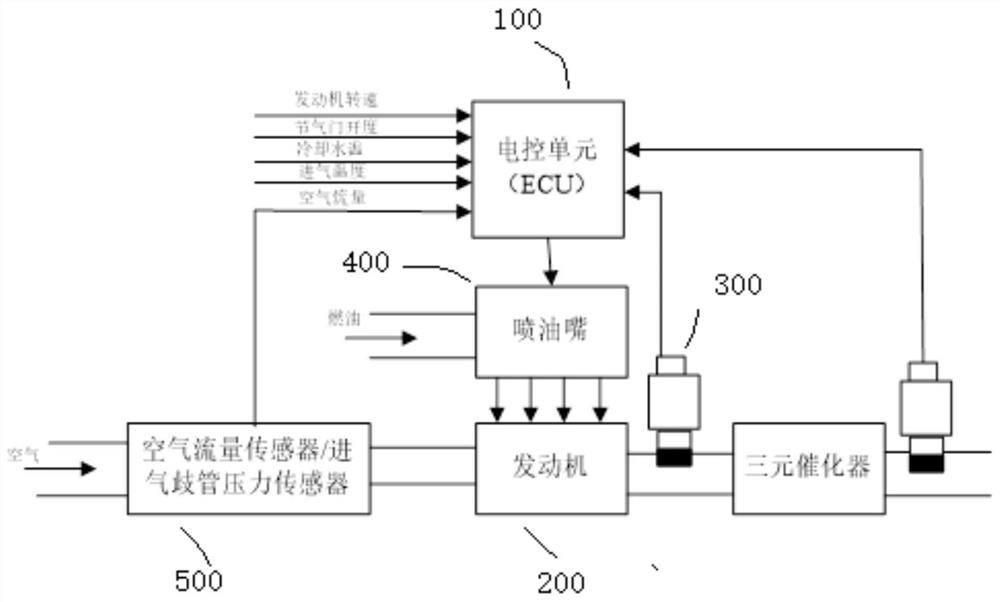

Single-cylinder air-fuel ratio closed-loop control method based on oxygen sensor for multi-cylinder engine

A multi-cylinder engine and oxygen sensor technology, applied in engine control, machine/engine, fuel injection control, etc., can solve the problems of inapplicability, heavy test workload, etc., to reduce fuel consumption, improve control inhomogeneity, improve The effect of power torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following specific implementation methods are used to explain the technical solutions of the claims of the present invention, so that those skilled in the art can understand the claims. The protection scope of the present invention is not limited to the following specific implementation structures. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

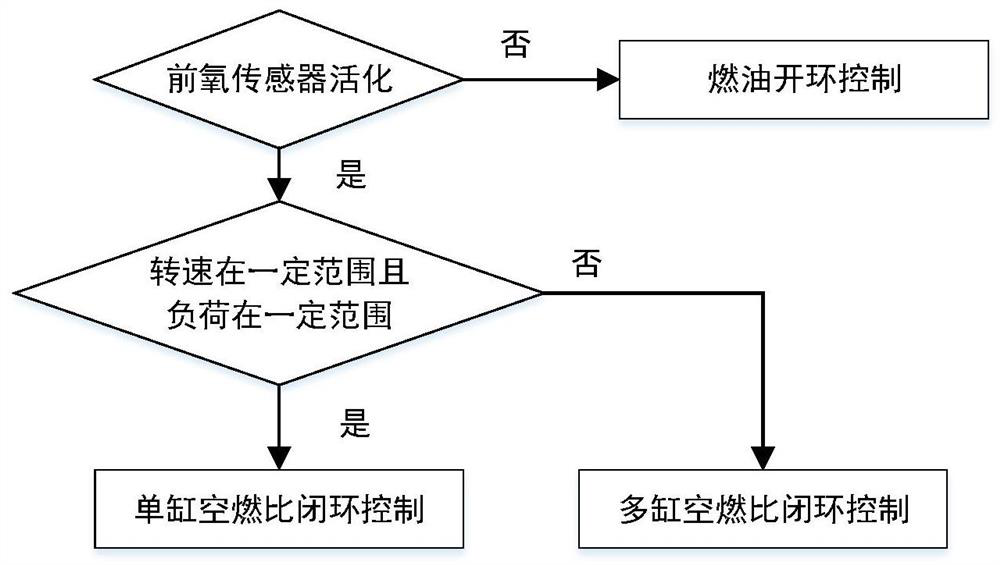

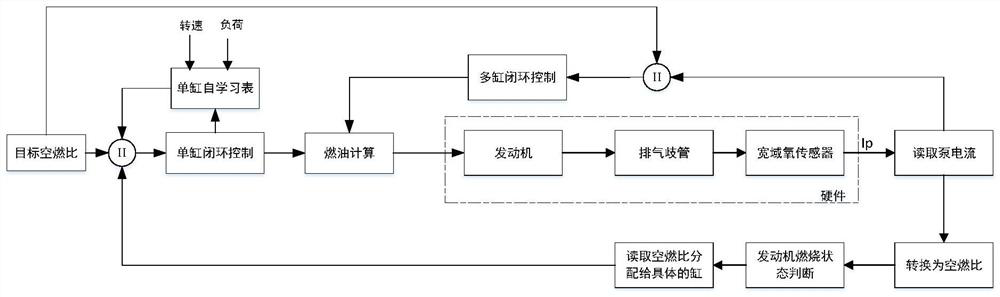

[0031] The present invention is applicable to various multi-cylinder engines in the process of implementing engine air-fuel ratio control, as long as the single-cylinder air-fuel ratio control condition is triggered, the single-cylinder air-fuel ratio control is implemented. The present invention relates to the control of fuel injection amount (fuel injection pulse width). The sampling time (sampling point) of the oxygen sensor can be set based on the structure and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com