Atkinson cycle engine air-fuel ratio control system

A control system, air-fuel ratio technology, applied in the direction of engine control, combustion engine, fuel injection control, etc., can solve the problem of slow transient response of air-fuel ratio control, no air-fuel ratio feed-forward controller, and no consideration of residual exhaust gas in the cylinder. Air backflow and other issues can be improved to improve transient response and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

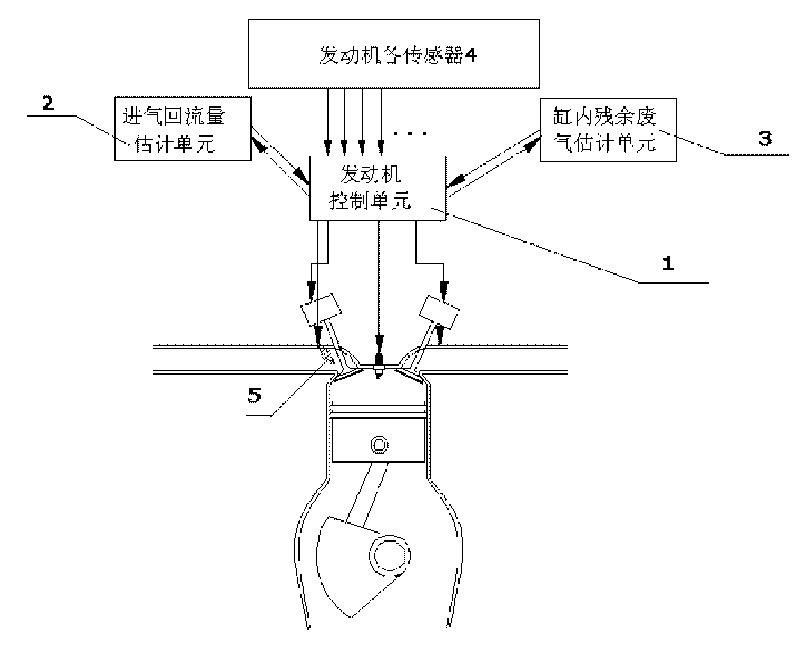

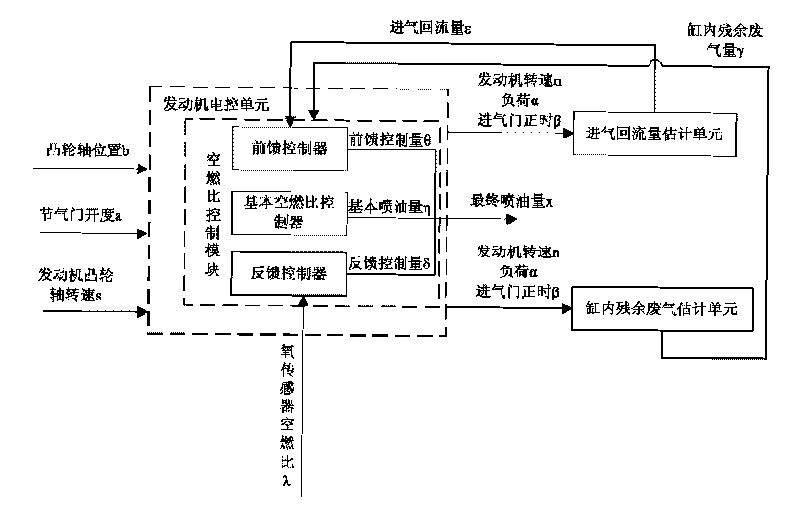

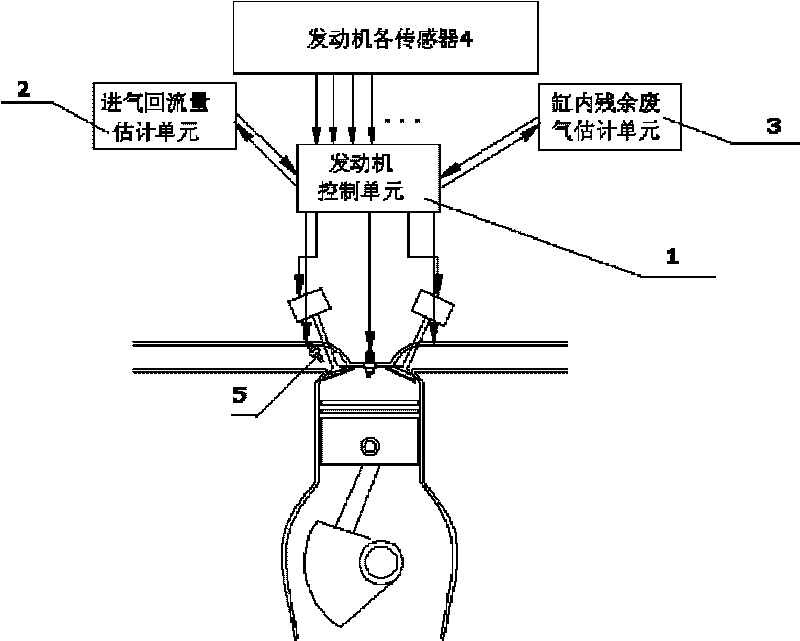

[0017] like figure 1 As shown, this embodiment includes: an engine electronic control unit 1, an intake air return estimation unit 2, a residual exhaust gas estimation unit 3, a sensor system 4 and a fuel injector 5, wherein: the engine electronic control unit 1 is provided with an air-fuel ratio control module, The engine electronic control unit 1, the intake air return estimation unit 2, and the residual exhaust gas estimation unit 3 are connected through the CAN bus for real-time signal transmission. The sensor system 4 includes: an engine speed sensor, a throttle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com