Atkinson cycle engine control system and control method thereof

A control system, Atkinson's technology, applied in engine control, combustion engine, machine/engine, etc., can solve problems such as inability to reduce pumping loss, fuel economy, difficult control of air-fuel ratio, unstable engine combustion, etc., to eliminate Instability of combustion, reduced pumping losses, and the effect of optimizing fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

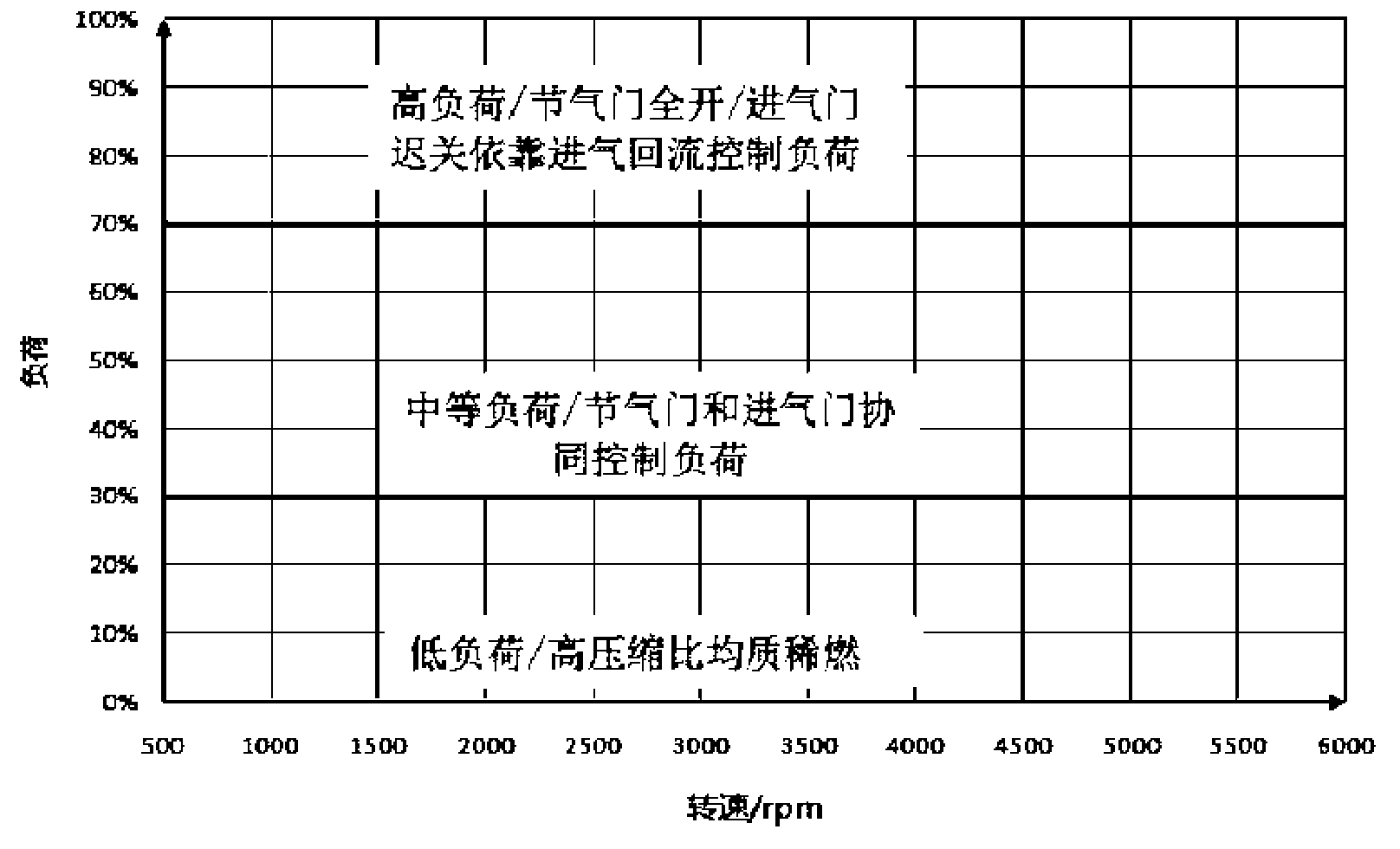

[0030] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

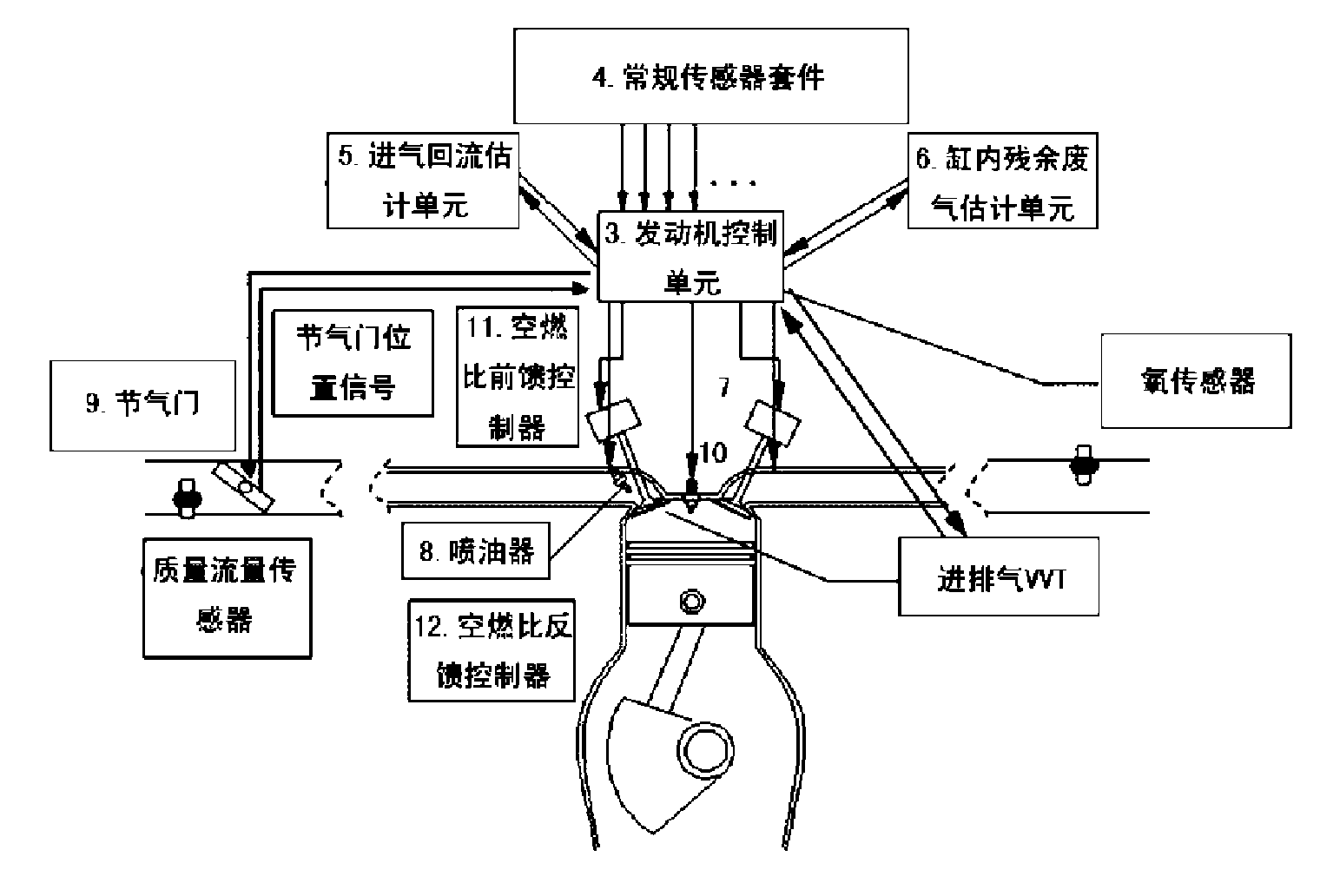

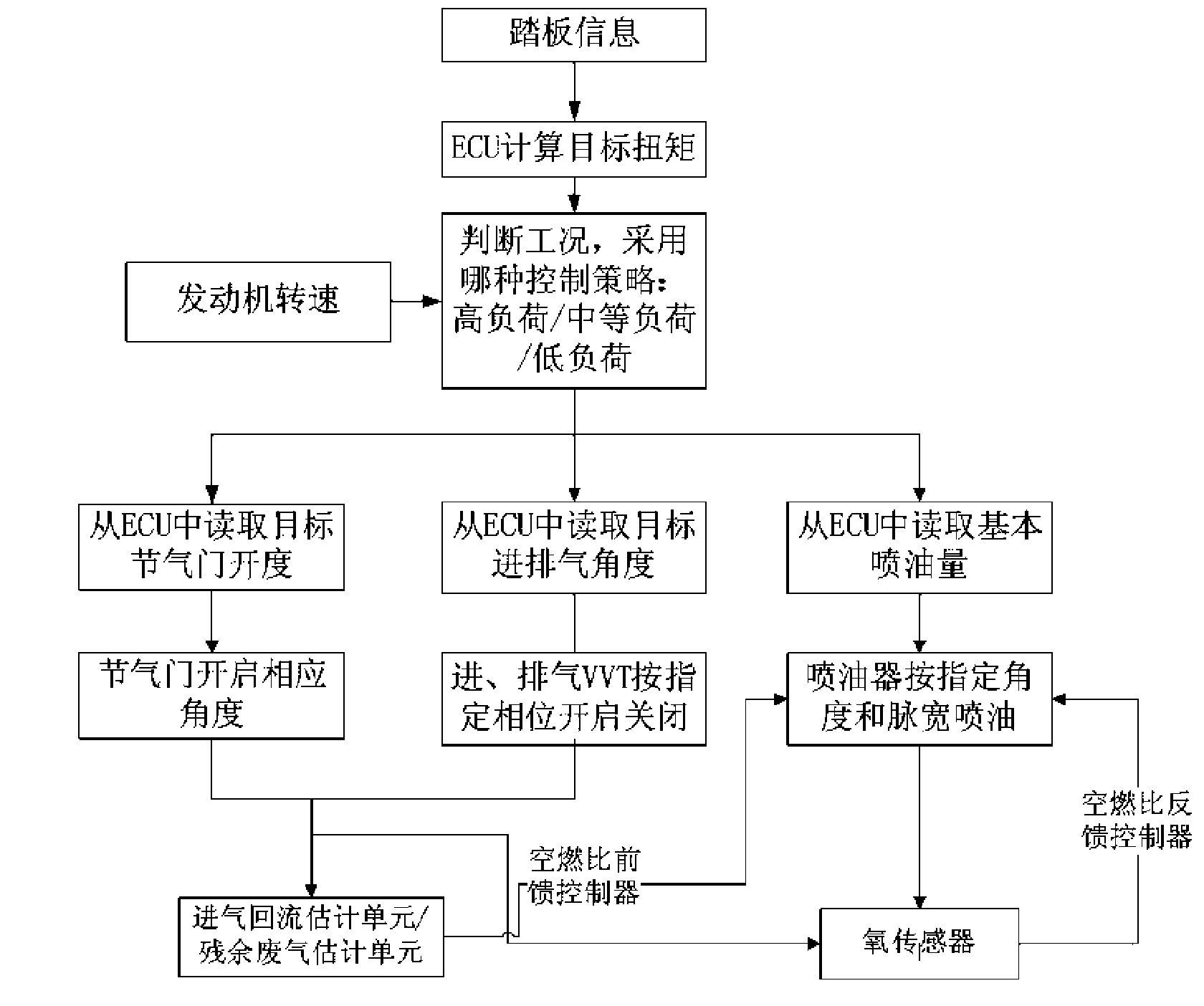

[0031] Such as figure 1 As shown, this example includes: a sensor system 1, a control actuator 2, and an engine control unit 3. The sensor system 1 inputs the collected signal into the engine control unit 3, and the output of the engine control unit 3 includes controlling the throttle valve 9, the fuel injector 8, and the control unit. Change the control commands of the intake and exhaust timing devices and the spark plug 10 to the control actuator 2.

[0032]The sensor system 1 includes: a conventional sensor set 4, an intake air return estimating unit 5 and an in-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com