A sodium ion softening water treatment regeneration agent

A regenerant and water softening technology, which is applied in complex/solubilizer treatment, etc., can solve problems such as condensed water pollution, excessive iron content in condensed water, unqualified condensed water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

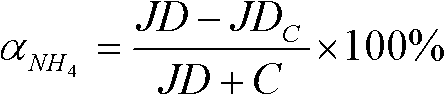

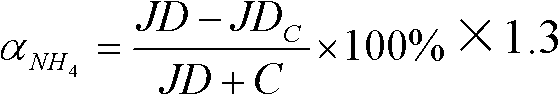

[0028] 1. Changes in water quality after softener regeneration

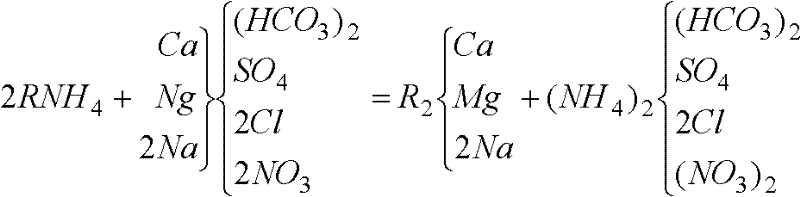

[0029] After ammonium chloride is added to the sodium chloride regenerant, the softener is regenerated with sodium chloride containing ammonium chloride after the softener fails. Part of the ion exchange resin is sodium type, and part is ammonium type. The following reactions occur when the raw water is softened:

[0030] (1) Exchange reaction of ammonium exchange resin

[0031] 2 RNH 4 + Ca Ng 2 Na ( HCO 3 ) 2 ...

Embodiment 2

[0052] Adopt regenerant regeneration softener described in the present invention, the NH that ammonium salt decomposes in pot 3 Bringing it into the steam can prevent CO from occurring in the metal of the steam equipment and the condensate system 2 Corrosion, greatly improve the quality of condensed water, ensure 100% qualified recovery of condensed water, and maximize the recovery and utilization of condensed water and heat energy.

[0053] The recycling rate of condensed water in industrial steam boilers can be increased to 92% by using the regenerant of the invention, 17.51 million tons of standard coal can be saved every year, and 2.6 billion cubic meters of industrial water can be saved.

[0054] Economic Benefit Analysis

[0055] The value of condensate recovery is directly reflected in three parts: heat energy value, condensate pure quality value and pollution reduction value. Now analyze the recovery benefits of coal-fired boilers and oil-fired boilers as follows

...

Embodiment 3

[0073] By adopting the regeneration agent of the present invention, after the ammonium salt enters the pot, the alkalinity of the pot water can be effectively reduced, and excessive sewage discharge caused by the alkalinity exceeding the standard can be prevented.

[0074] economic benefits

[0075] The value of reducing boiler blowdown rate is directly reflected in reducing heat energy loss, reducing water consumption and reducing environmental pollution. Let’s take a common industrial boiler as an example to analyze the benefits of boiler sewage reduction. A 6T / H boiler with a rated pressure of 1.25Mpa adopts condensed water recovery and utilization. It is 3.0mmol / L. It adopts sodium salt treatment and adopts regeneration agent of the present invention to deal with separately, and its water quality is as follows respectively:

[0076]

[0077] From the above water quality analysis results, it can be drawn that the water quality treated by the regenerant of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com