Method for recovering epoxy chloropropane from wastewater containing epoxy chloropropane

A technology of epichlorohydrin and waste water, applied in the direction of heating water/sewage treatment, organic chemistry, etc., can solve the problem that epichlorohydrin is difficult to obtain, and achieve the goal of reducing difficulty and cost, low operating cost, and large processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

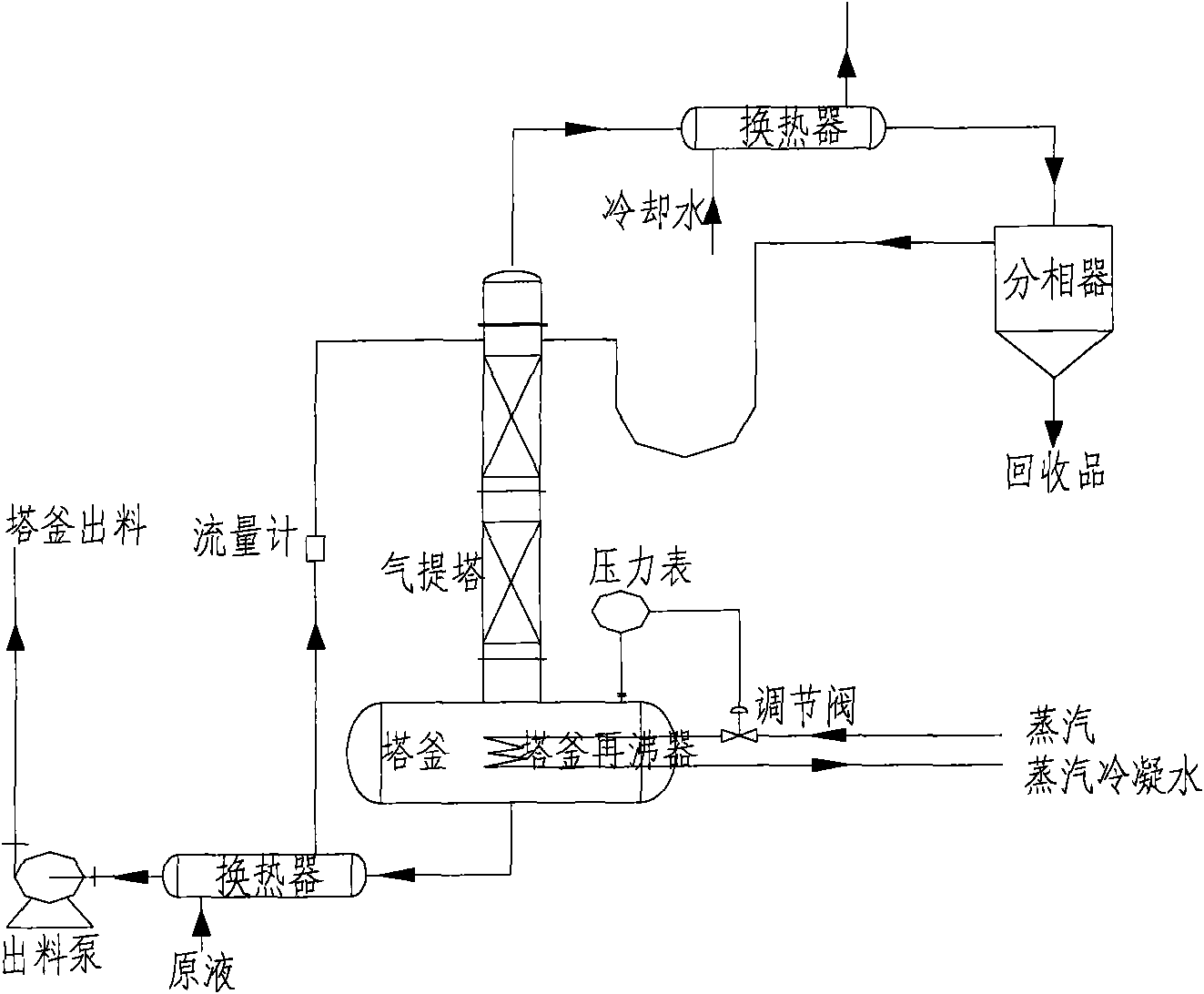

Image

Examples

Embodiment 1

[0023] Preheat the epichlorohydrin wastewater with a content of about 3%, a COD of 72216mg / L, and a COD (chemical oxygen demand, the same below) of 72216mg / L to 80°C, and then use 1.5-2m 3 The flow rate of / h is pumped from the top of the tower to the stripping tower, the pressure of the bottom of the tower is controlled to 0.0029-0.0030Mpa, the temperature of the top of the tower is ≥95°C, and 99.2% of epichlorohydrin is obtained from the phase separator. The COD discharged from the tower kettle is 17136mg / L, and the COD is 23.73% of the original.

Embodiment 2

[0025] Preheat the epichlorohydrin wastewater with an epichlorohydrin content of 2% and a COD of 48144mg / L to 60°C in a 1.5m 3 The flow rate of / h is pumped into the stripping tower from the top of the tower, the pressure of the bottom of the tower is controlled to 0.0029-0.0030Mpa, the temperature of the top of the tower is ≥95°C, and 99.3% of epichlorohydrin is obtained from the phase separator. The COD discharged from the tower kettle was 11352mg / L, and the COD decreased by 76.42%.

Embodiment 3

[0027] Preheat the epichlorohydrin waste water with 5% epichlorohydrin content and 180540 mg / L COD to 90 ° C and use 2m 3 The flow rate per hour is pumped into the stripping tower, the pressure in the bottom of the tower is controlled to 0.0029-0.0030Mpa, the temperature at the top of the tower is ≥95°C, and 99.1% of epichlorohydrin is obtained from the phase separator. The COD discharged from the tower kettle was 43347mg / L, and the COD was reduced by 75.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com