Method of optimizing the specific fuel consumption of a twin engine helicopter and twin engine architecture with control system for implementing it

A technology of fuel consumption rate, optimization method, applied in the direction of engine components, machine/engine, turbine/propulsion fuel delivery system, etc., can solve problems such as the danger of engine landing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

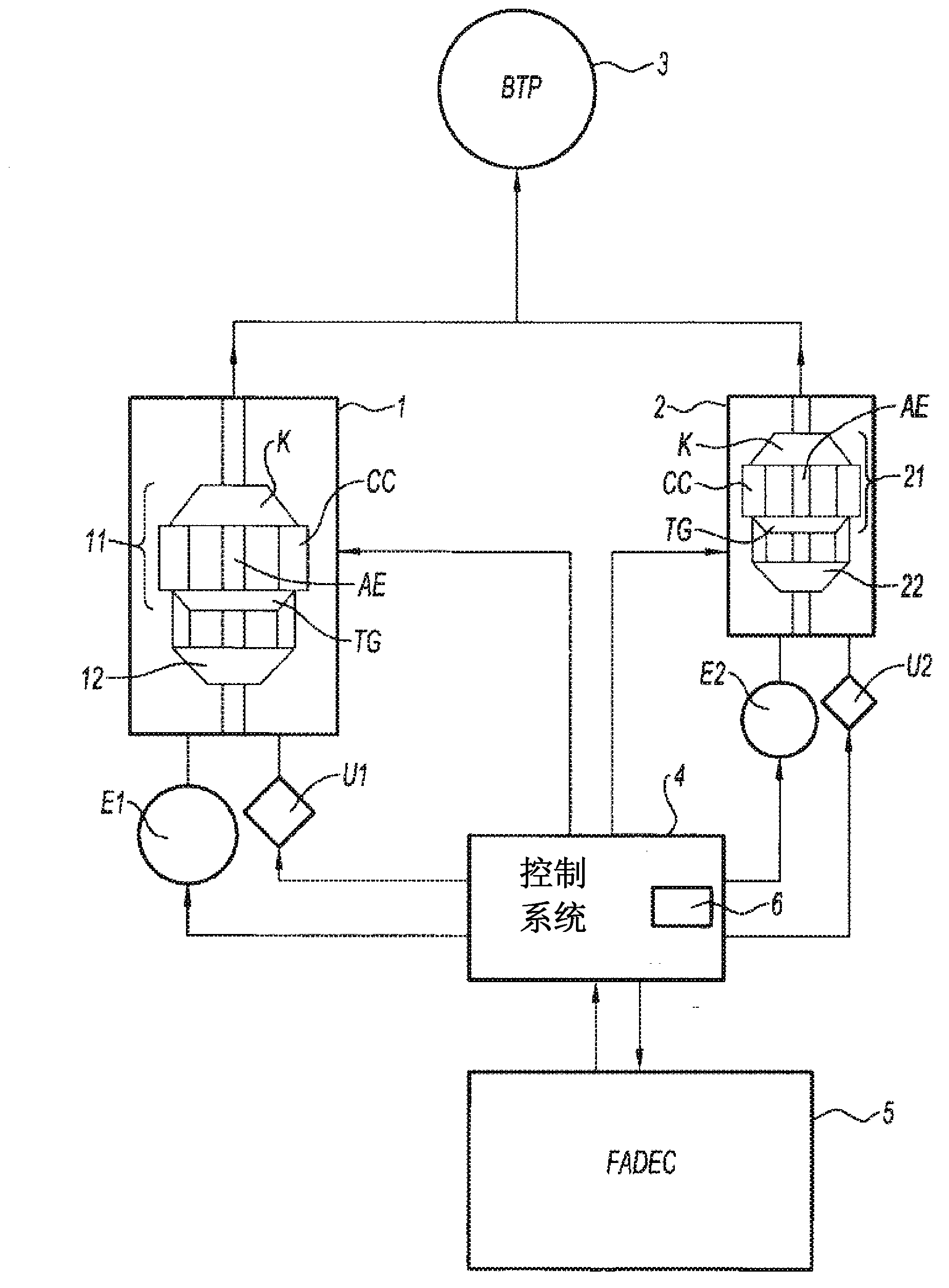

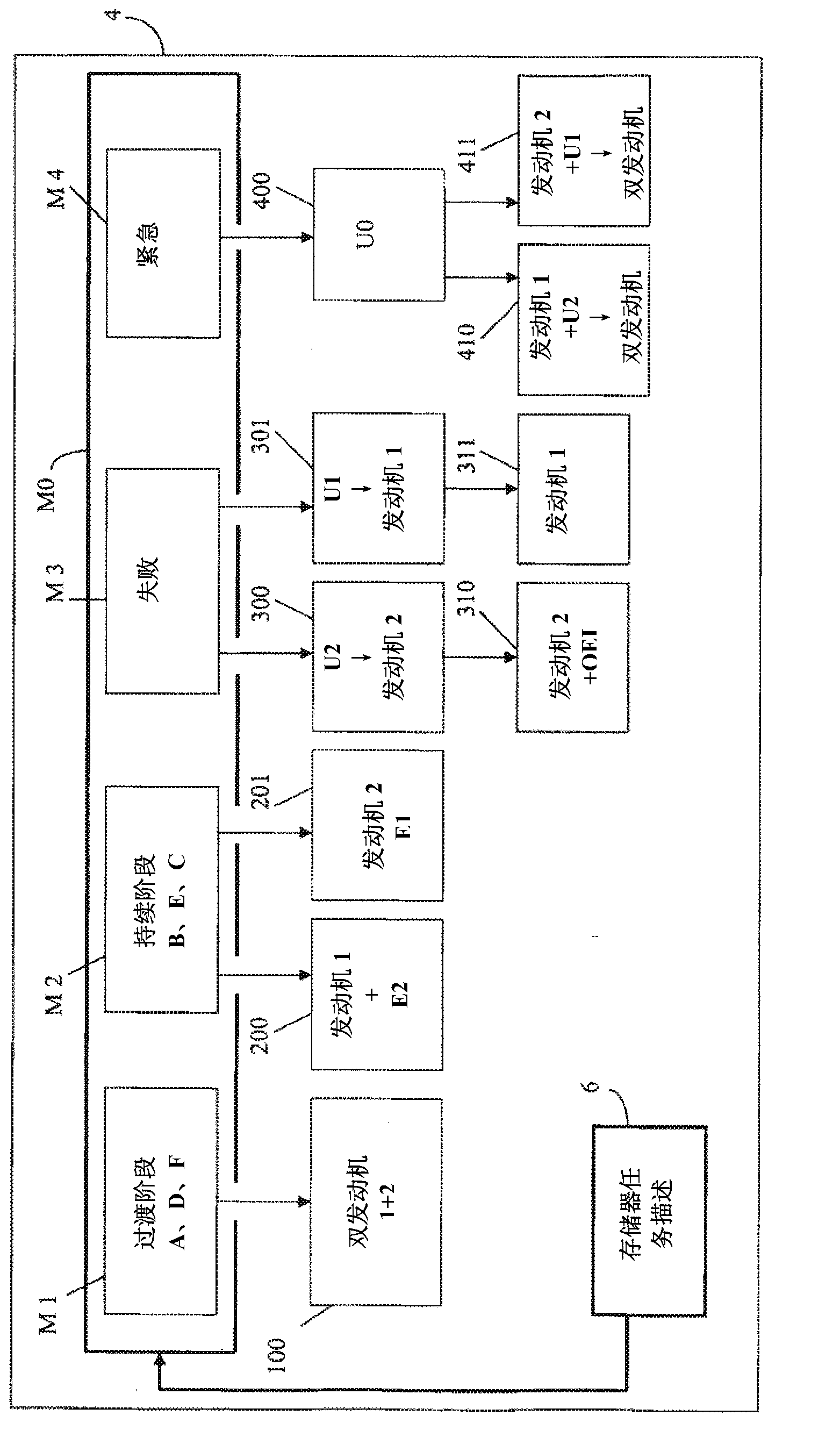

[0042] In the present specification, the terms "engine" and "turbine engine" are used synonymously. In the illustrated embodiment, the engines have different maximum powers from each other. Advantageously, the described embodiment eliminates the one engine inactive (OEI) speed of the most powerful turbine engine, thereby minimizing the difference in mass between the two engines. To simplify language, the most powerful engines or oversized engines are also referred to as "large" engines, and the least powerful engines are also referred to as "small" engines.

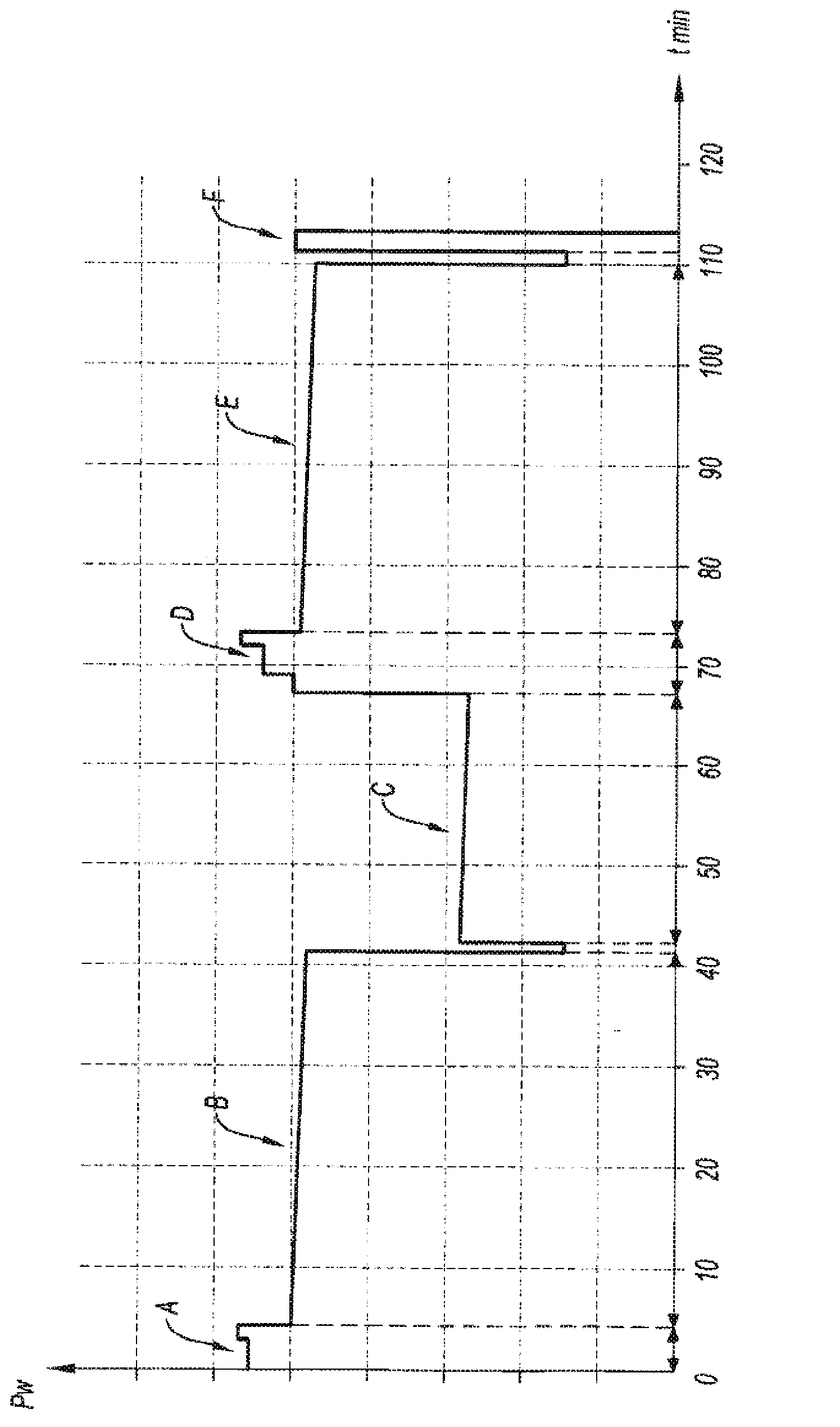

[0043] figure 1 The schematic diagram shows the change of the total power Pw required by the twin-engine helicopter at different times "t" when performing rescue missions for shipwrecked personnel. This task consists of six main phases:

[0044] Takeoff phase "A" using maximum takeoff power (MTOP);

[0045] Cruise flight phase "B" for transit to the search area, during which the power level is less than or equal to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com