Method for optimising the specific consumption of a twin helicopter

An optimization method, helicopter technology, applied in the direction of engine components, machines/engines, rotorcraft, etc., to achieve the effect of reducing fuel consumption, temperature and fuel consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The terms "engine" and "turboshaft engine" are used synonymously in this document. In the illustrated embodiment, the engines have different maximum powers. Advantageously, this embodiment makes it possible to suppress the OEI speed on the more powerful turboshaft engine, and this minimizes the difference in mass between the two engines. To simplify language, the most powerful engine or oversized engine may also be referred to as a "large" engine, while the smallest powered engine may be referred to as a "small" engine.

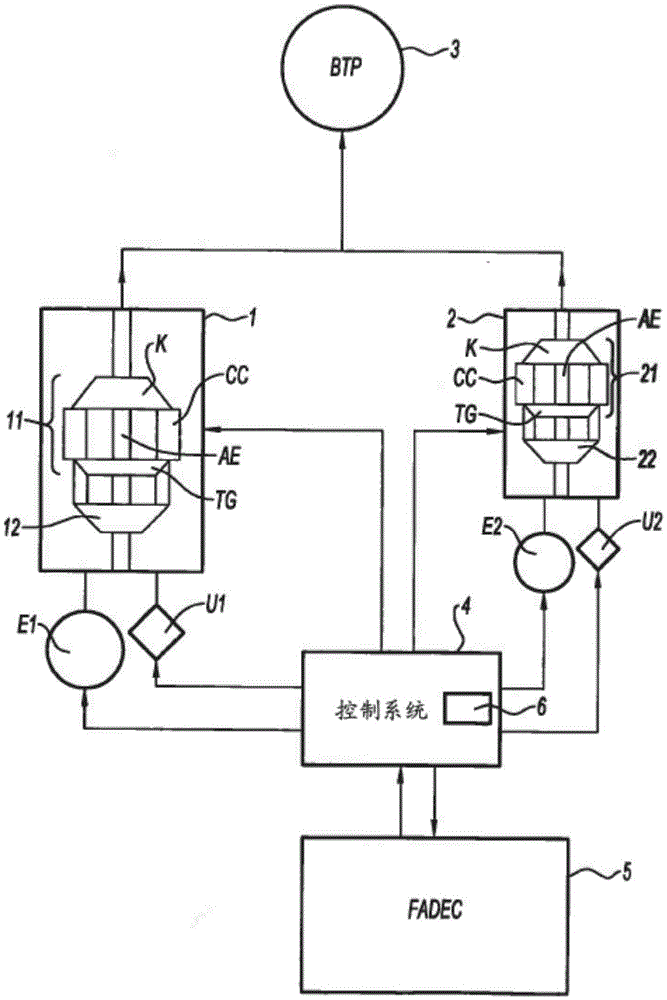

[0024] The drawings schematically show an example of a structure of a twin-engine helicopter capable of optimizing the specific consumption Cs.

[0025] Typically, each turboshaft engine 1 , 2 comprises a gas generator 11 , 21 and a free turbine 12 , 22 fed by the gas generator to provide power. During takeoff and at continuous speed, the power supplied may reach predetermined maximum values PMD and PMC, respectively. In general, a gas generator c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com