Macrocrystalline sintered plate-shaped corundum and preparation method thereof

A tabular corundum and crystallization technology, applied in the field of refractory materials, can solve the problem of not meeting the use requirements of high-end products, and achieve the effects of good wear resistance, improved wear resistance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

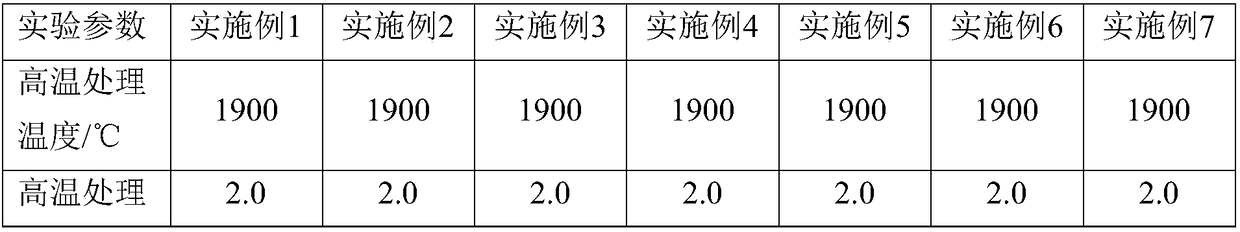

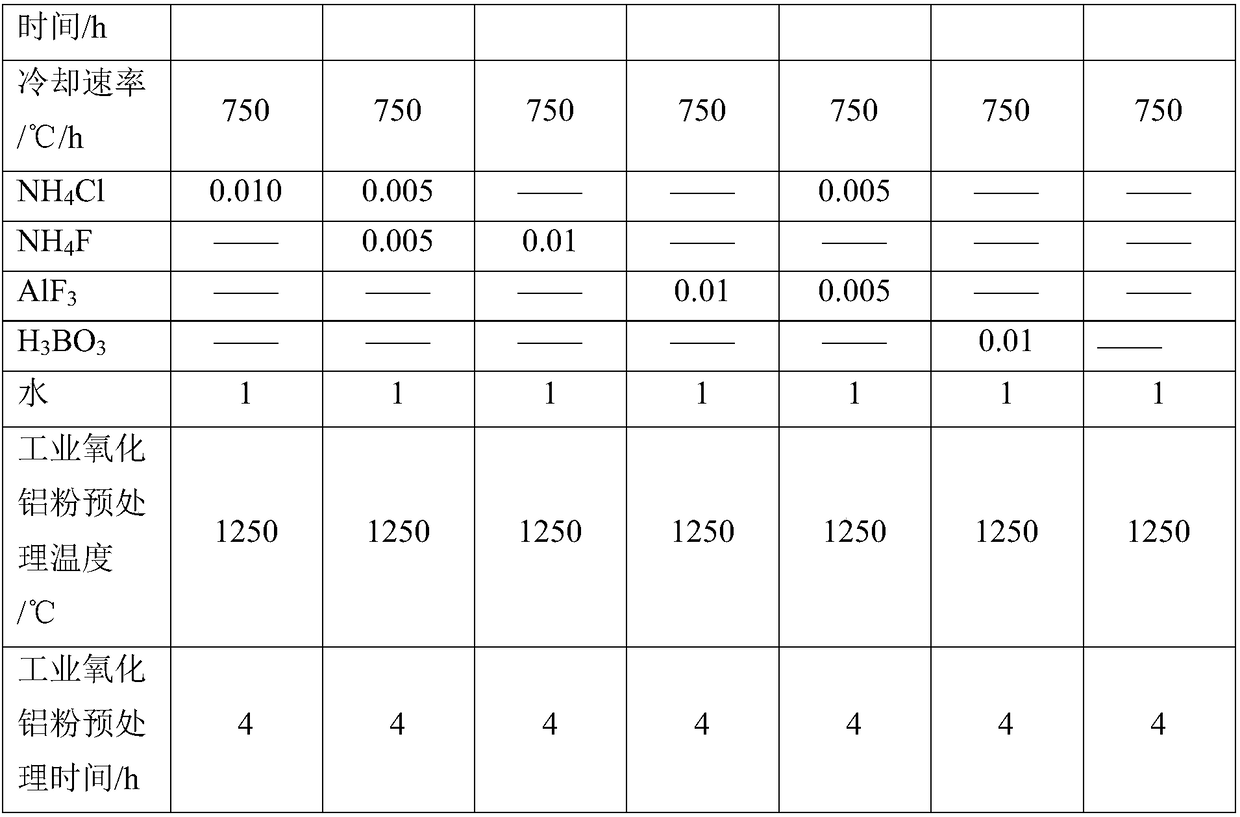

[0038] A method for preparing large crystal sintered tabular alumina, the process flow of which is as follows:

[0039] (1) The industrial alumina powder is pretreated at high temperature, and the pretreatment temperature and pretreatment time of the industrial alumina powder are shown in Table 1. In the product after high temperature treatment, the weight percentages of each component are respectively: Al 2 o 3 ≥99.0%, SiO 2 ≤0.05%, CaO≤0.08%, Fe 2 o 3 ≤0.06%, Na 2 O≤0.4%.

[0040] In the present invention, unless otherwise specified, percentages are percentages by weight.

[0041] (2) Grinding

[0042] Put the product after the high-temperature treatment in step (1) into a grinder and grind it. The ball ratio (mass ratio) during grinding is large ball (diameter 60mm): small ball (diameter 40mm) = 1: 4.5, feed amount It is 120kg / h, the speed of the classifier is 1000r / min, and the output product particle size is controlled at -45μm≥90wt% (that is, the powder with a ma...

Embodiment 1

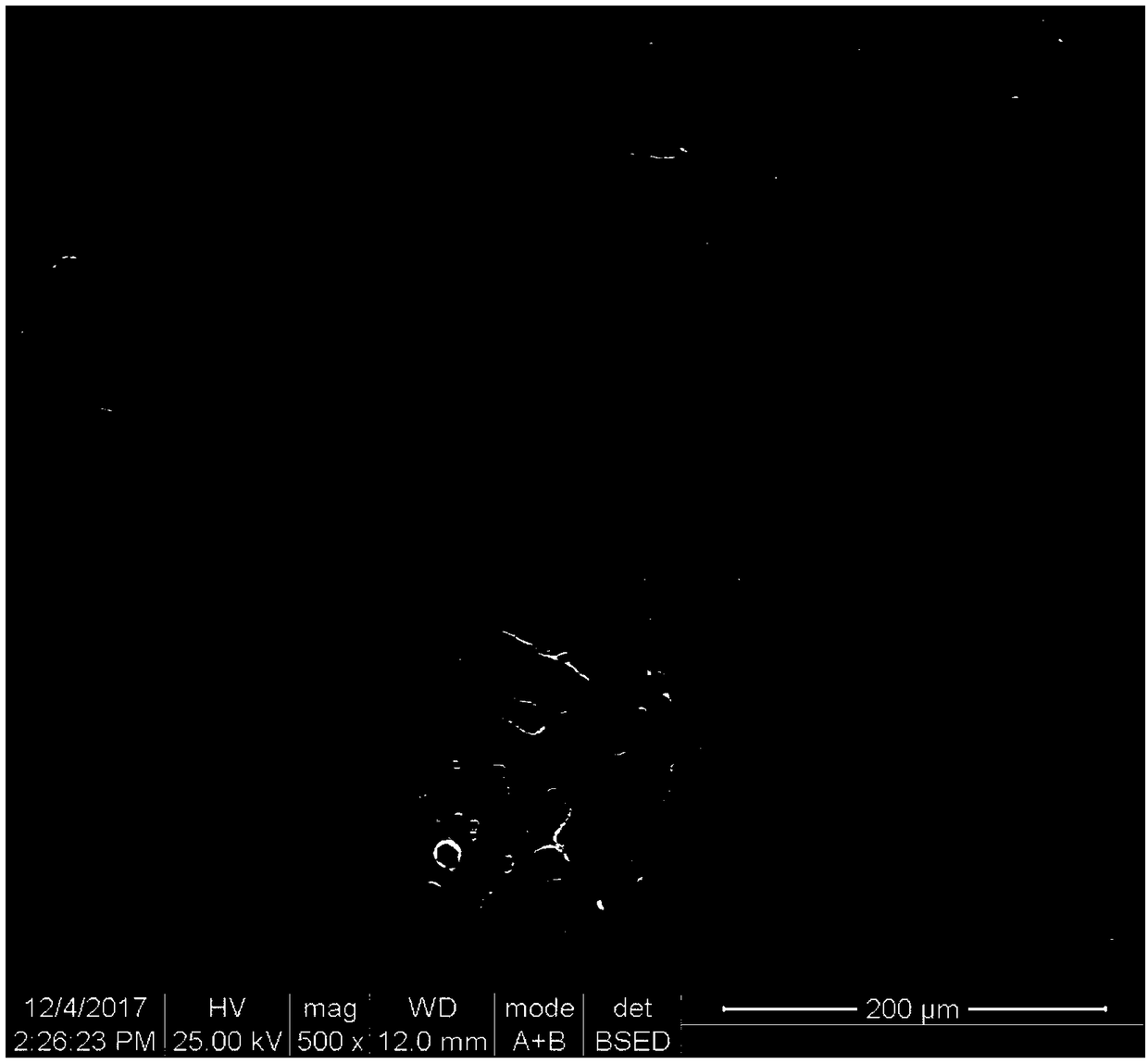

[0077] The electron microscope picture of the sintered tabular alumina prepared in Example 1 is as follows figure 1 As shown, the grain size is 350 μm, and there are a large number of micropores with diameters below 10 μm inside the grains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com