Preparation method of high-corrosion-resistance pleonaste brick

A spinel brick and magnesia-iron technology, which is applied in the field of preparation of high-corrosion magnesia-iron spinel bricks, can solve problems such as short service life, improve thermal shock resistance, increase service life, and improve high-temperature corrosion resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-corrosion-resistant magnesia-iron spinel brick, whose raw materials include the following ingredients: 85 parts of high-purity large-crystal fused magnesia, 15 parts of ultra-fine fused magnesia powder, and 10 parts of metal magnesium powder And 2 parts of binding agent, the binding agent is water glass, the content of magnesium oxide in the high-purity large crystal fused magnesia is 88%, and the content of ferric oxide is 3%.

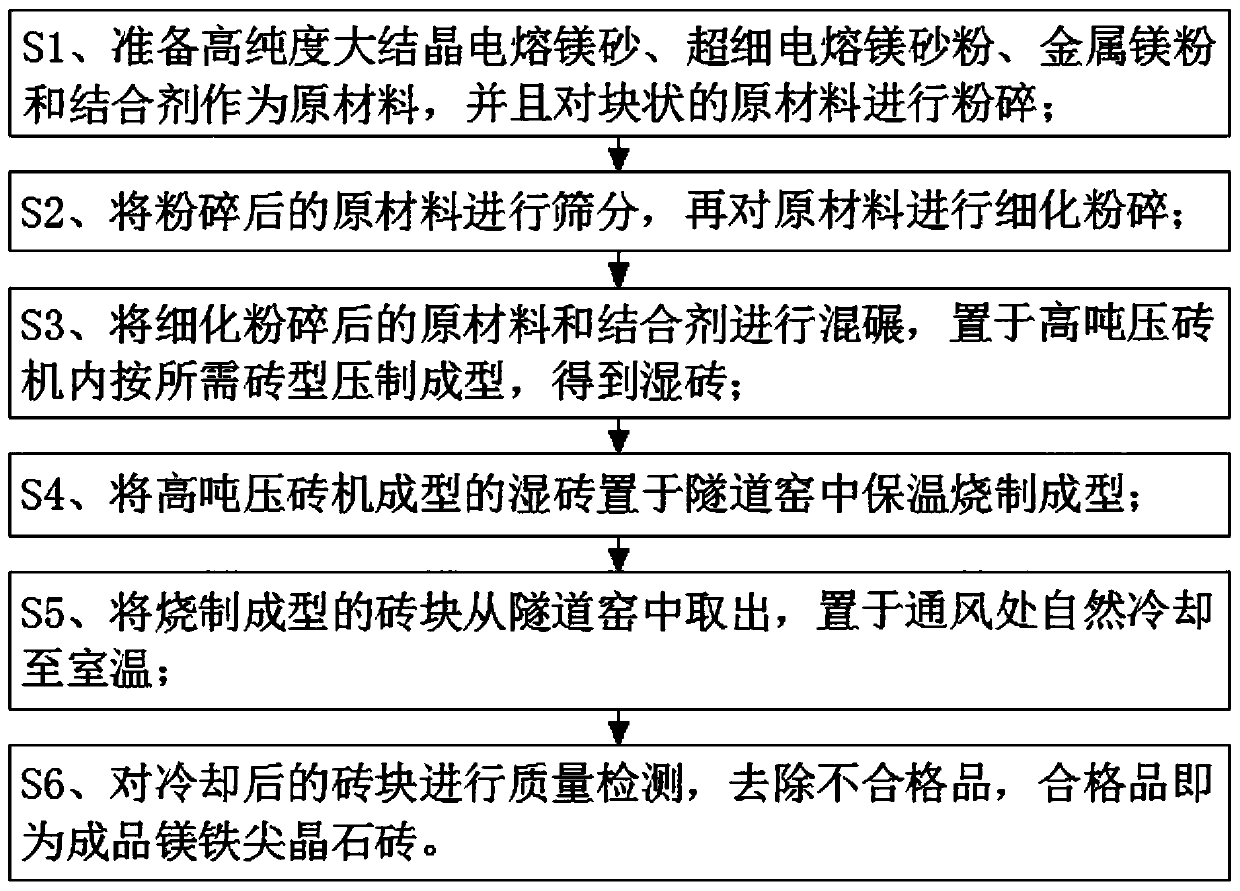

[0026] A method for preparing a high-corrosion magnesia-iron spinel brick, comprising the following steps:

[0027] S1. Prepare high-purity large crystal fused magnesia, ultra-fine fused magnesia powder, metal magnesium powder and binder as raw materials, and pulverize the bulk raw materials;

[0028] S2, screening the crushed raw materials, and then finely crushing the raw materials;

[0029] S3. Mix and grind the finely crushed raw materials and binders, place them in a high-ton brick press and press them according to the required bri...

Embodiment 2

[0034] A high-corrosion-resistant magnesia-iron spinel brick, whose raw materials include the following ingredients: 88 parts of high-purity large-crystal fused magnesia, 20 parts of ultra-fine fused magnesia powder, and 20 parts of metal magnesium powder And 4 parts of binding agent, the binding agent is sodium tripolyphosphate, the content of magnesium oxide in the high-purity large crystal fused magnesia is 92%, and the content of ferric oxide is 4%.

[0035] A method for preparing a high-corrosion magnesia-iron spinel brick, comprising the following steps:

[0036] S1. Prepare high-purity large crystal fused magnesia, ultra-fine fused magnesia powder, metal magnesium powder and binder as raw materials, and pulverize the bulk raw materials;

[0037] S2, screening the crushed raw materials, and then finely crushing the raw materials;

[0038] S3. Mix and grind the finely crushed raw materials and binders, place them in a high-ton brick press and press them according to the ...

Embodiment 3

[0043] A high-corrosion-resistant magnesia-iron spinel brick, whose raw materials include the following ingredients: 90 parts of high-purity large-crystal fused magnesia, 25 parts of ultra-fine fused magnesia powder, and 25 parts of metal magnesium powder And 5 parts of binding agent, the binding agent is sodium hexametaphosphate, the content of magnesium oxide in the high-purity large crystal fused magnesia is 98%, and the content of ferric oxide is 5%.

[0044] A method for preparing a high-corrosion magnesia-iron spinel brick, comprising the following steps:

[0045] S1. Prepare high-purity large crystal fused magnesia, ultra-fine fused magnesia powder, metal magnesium powder and binder as raw materials, and pulverize the bulk raw materials;

[0046] S2, screening the crushed raw materials, and then finely crushing the raw materials;

[0047] S3. Mix and grind the finely crushed raw materials and binders, place them in a high-ton brick press and press them according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com