High-temperature treated magnesia carbon brick for RH dip pipe and circulating pipe and preparation method thereof

A technology of high-temperature treatment and magnesia-carbon bricks, which is applied in the field of refractory materials for iron and steel smelting RH vacuum refining furnaces. It can solve the problems of large porosity and general high-temperature strength performance, so as to reduce porosity, strong slag erosion resistance, and improve product quality. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A high-temperature heat-treated magnesia-carbon brick for RH dipping pipes and circulation pipes. The raw material formula is shown in Table 1:

[0048] Table 1: the raw material formula of embodiment 1

[0049]

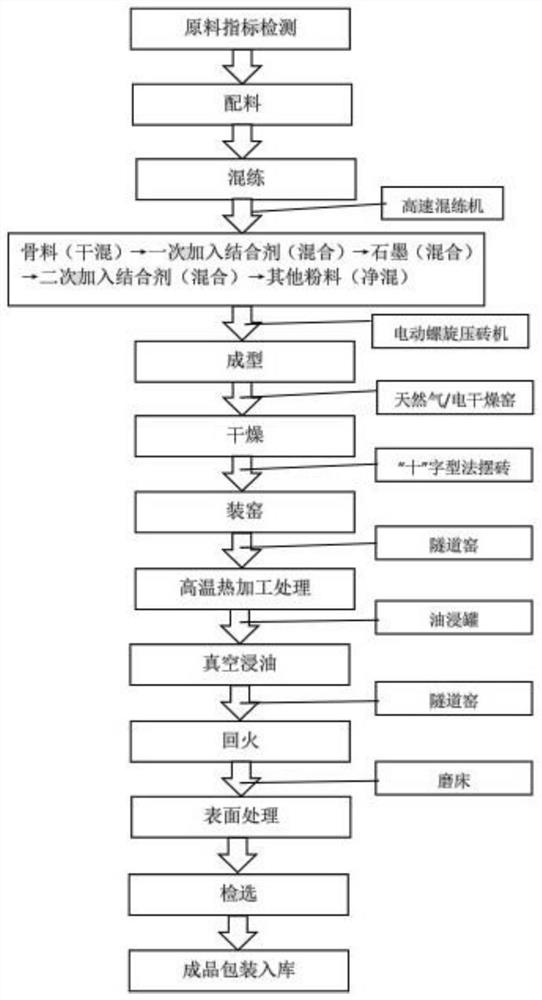

[0050] The manufacturing method of high-temperature heat-treated magnesia-carbon bricks for RH dipping pipes and circulation pipes is as follows:

[0051] 1) Raw material index detection.

[0052] 2) Ingredients: Accurately prepare each material according to the above weight parts for later use.

[0053] 3) Mixing (600L high-speed mixing machine, model: HNG-600L):

[0054] a. Coarse and medium grain magnesia (3-5mm, 1-3mm, 0-1mm) dry mixed for 2 minutes;

[0055] b. Add 2 / 3 of the total amount of resin (resin temperature 25-35°C) and mix for 3 minutes;

[0056] c. Add graphite and mix at low speed for 3 minutes;

[0057] d. Add the remaining resin and mix for 1 min;

[0058] e. Turn off the kneader and add magnesia with a particle size of ≤0.075mm, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com