Closed device for producing macrocrystalline fused magnesite

A closed-type fused magnesia technology is applied in the field of large crystal fused magnesia production and processing devices to achieve the effects of reducing heat loss, reducing energy consumption, and improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

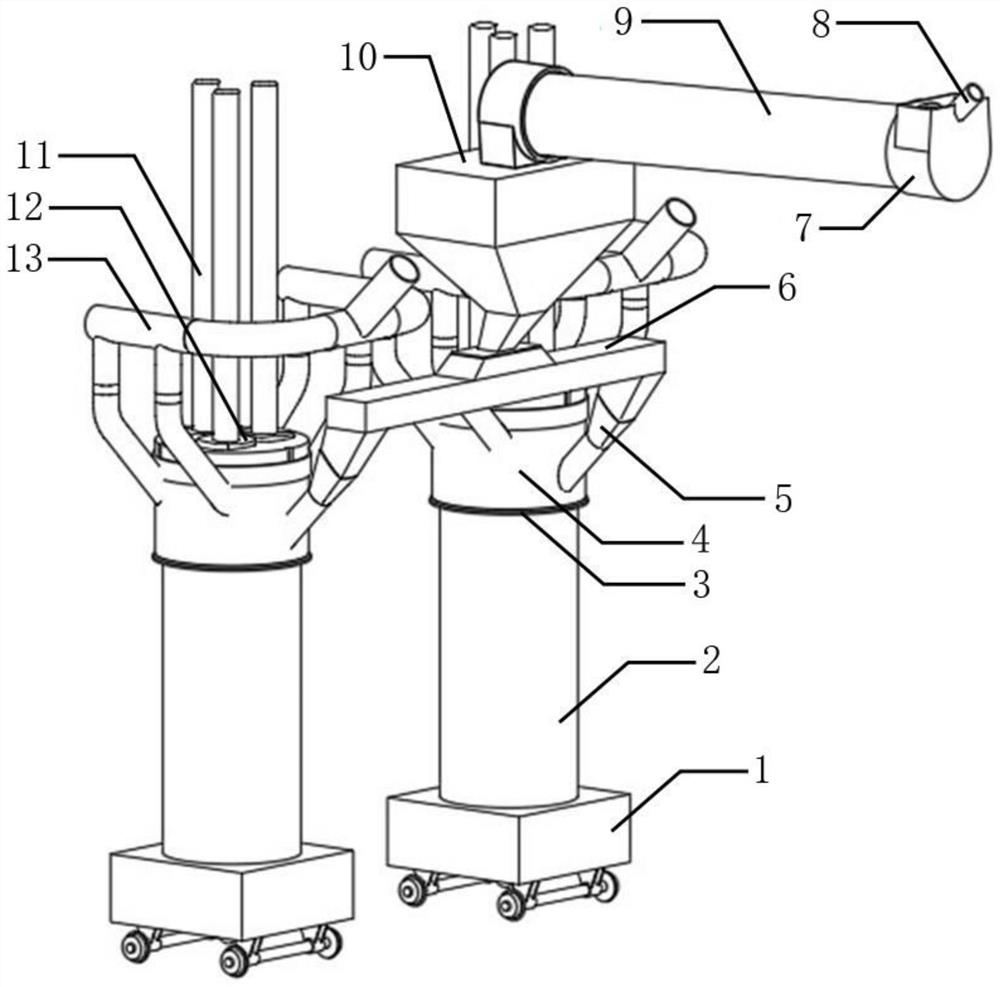

[0026] Such as figure 1 As shown, the device for the closed production of large crystal fused magnesia includes a light-burned magnesia kiln and a submerged arc furnace, and the light-burned magnesia kiln is connected with the chain grate feeder 6 through an intermediate warehouse 10, Multiple sets of submerged arc furnaces are matched and docked through the grate feeder 6.

[0027] The light-burned magnesia kiln is a kiln for producing light-burned magnesia, which can be a shaft kiln, a rotary kiln, a fluidized fluidized furnace, etc. The present invention uses a rotary kiln 9 . The front end of the rotary kiln 9 is provided with a rotary kiln hood 7, and the rotary kiln hood 7 is provided with a light-burned magnesia powder slide pipe 8 for introducing light-burned magnesia powder. The rear end of the rotary kiln 9 is connected to the intermediate bin 10, and the lightly burned magnesium oxide powder just out of the kiln is transported to the intermediate bin 10 for storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com