Process for smelting macrocrystalline green silicon carbide

A technology of green silicon carbide and process, which is applied in the field of large crystal green silicon carbide smelting process, can solve the problems of small green silicon carbide crystal grains, high smelting cost, unreasonable cloth, etc., and achieve compact and firm structure, high content, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

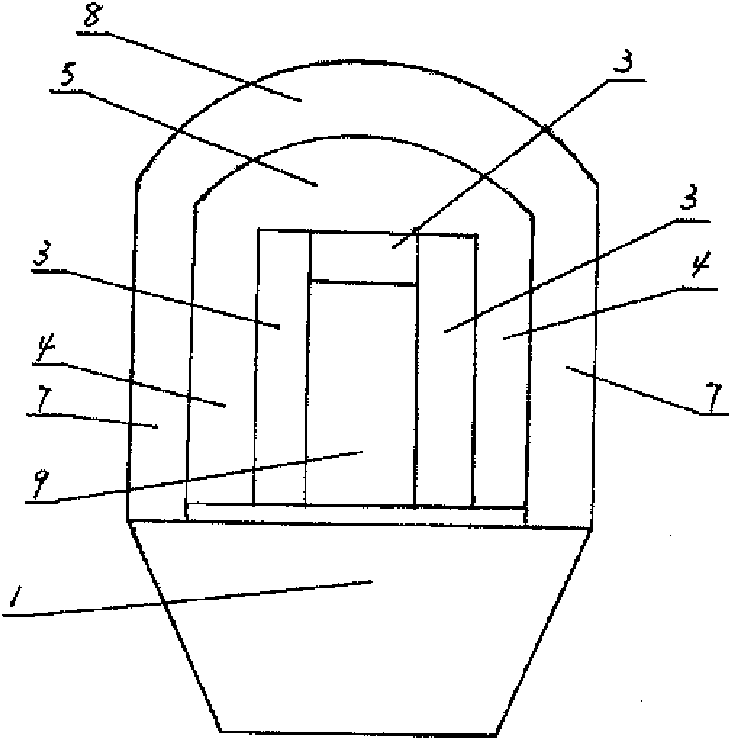

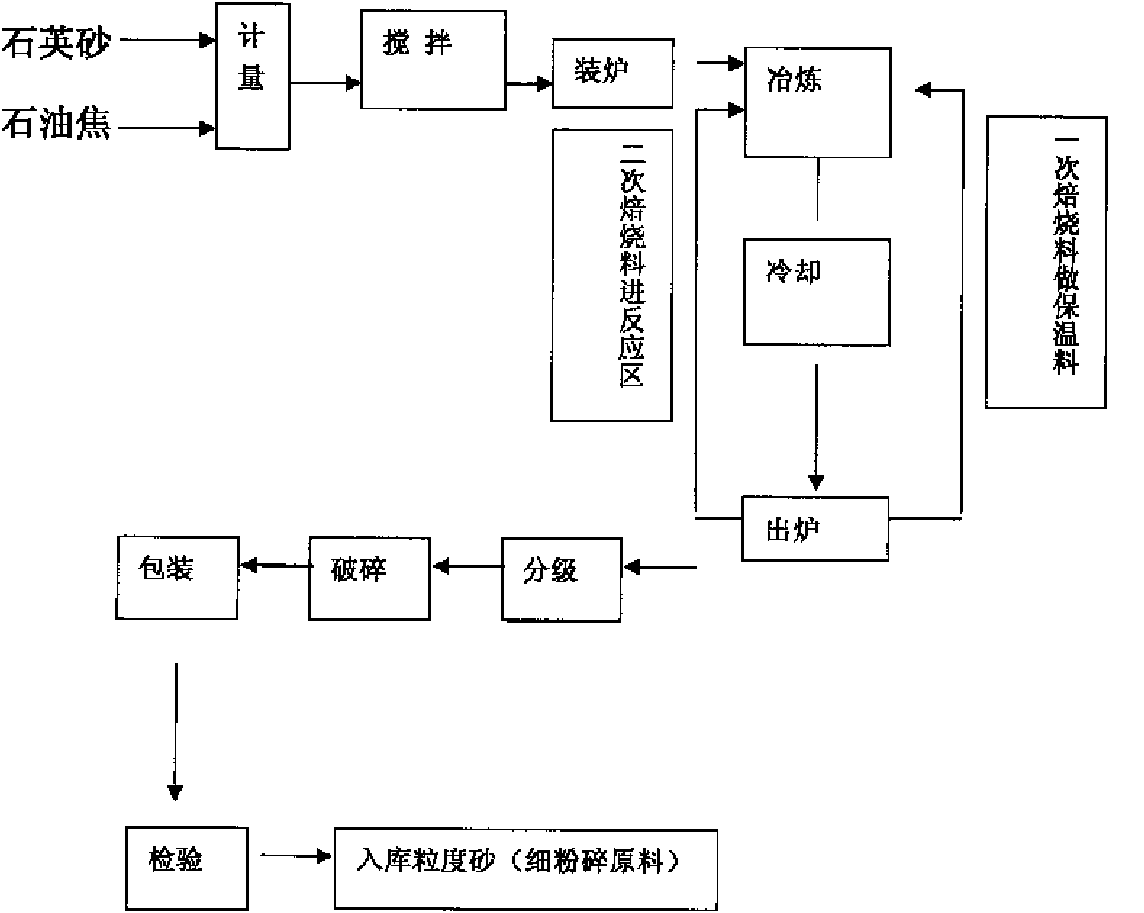

[0015] see figure 1 , 2 , the large crystal green silicon carbide smelting process includes the following steps: the secondary roasting process will purchase the quartz sand and petroleum coke that meet the quality requirements according to the formula of Si:C ratio of 1.48-1.54, and put them into the mixer for metering and stirring to achieve homogenization . The homogenized raw materials are transported into the furnace bottom (furnace bottom material area 1) for primary roasting, the furnace middle reaction zone III part material area 3, the furnace middle reaction zone IV part material area 4 and the furnace middle reaction zone V part material area 5 Load the charge after the secondary roasting, the material area 7 of the external heat preservation zone VII part, and the material area 8 of the external heat preservation zone VIII are filled with the material after the primary roasting for secondary roasting. The installed furnace is energized for about 32-36 hours for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com