Macrocrystal particles capable of forming crystal flower, dry particle combination, particles for ceramic, ceramic and preparation method of ceramic

A technology of particles and ceramics, applied in the field of ceramics, to achieve excellent decorative effects, rich and diverse colors, and a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

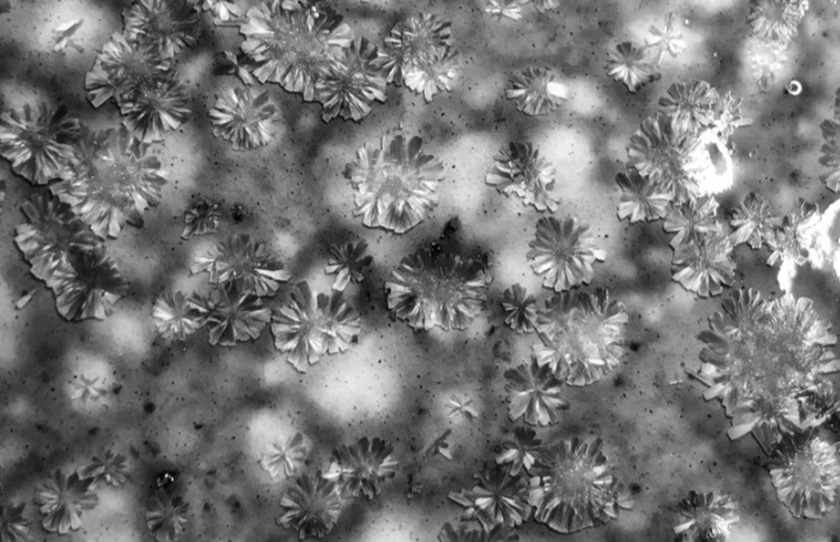

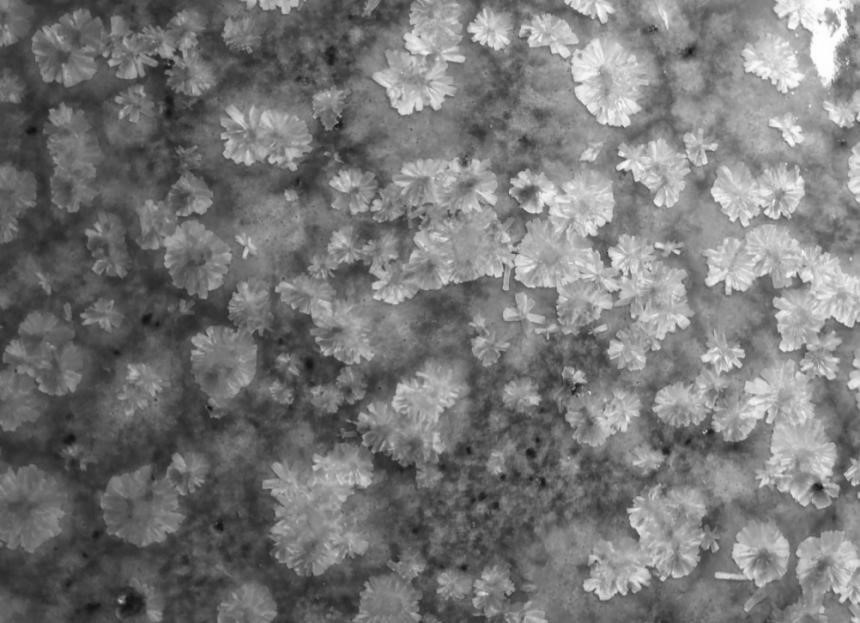

Image

Examples

preparation example Construction

[0092] A preparation method capable of forming crystal flower ceramics, comprising distributing the macrocrystalline particles described in the first aspect of the present invention, the combination of dry particles described in the second aspect of the present invention and the combination of dry particles described in the third aspect of the present invention in the glaze layer At least one of the above-mentioned particles for ceramics is obtained by firing.

[0093] In some examples, the process of the preparation method includes but is not limited to:

[0094]Green body process: at least one of the macrocrystalline particles described in the first aspect of the present invention, the dry particle combination described in the second aspect of the present invention, and the ceramic particles described in the third aspect of the present invention are mixed into or Digital positioning cloth into whole body or thin layer fabric, press molding, glazed or unglazed, fired, fully p...

Embodiment 1

[0108] Low-temperature fast-burning giant crystal particles, the raw material composition is: 5 parts of feldspar, 30 parts of quartz, 0 parts of alumina, 25 parts of zinc oxide, 5 parts of lithium carbonate, 4 parts of fluorite, 0 parts of wollastonite, cobalt oxide is 5wt% of the total mass of giant crystal particles; according to the composition ratio, the ingredients are mixed evenly and then put into the frit furnace to burn the frit. The range of broken particles is 10-60, 60-120, 120-200 mesh.

[0109] Mix these different particle sizes according to a certain ratio, directly spread on the inkjet surface glaze, and fire it in a kiln, with or without throwing, to obtain a brick surface pattern with a good crystal flower effect on the glaze; or

[0110] Appropriately add binder to the powder below 200 mesh, mix well, and then granulate the rollers, the granulated particles are 4-40 mesh, 40-80 mesh, and the granulated particles are distributed on the surface of the adobe b...

Embodiment 2

[0113] Low-temperature fast-fired giant crystal particles, the raw materials are: 5 parts of potassium sodium feldspar, 36 parts of quartz, 1 part of alumina, 30 parts of zinc oxide, 10 parts of lithium carbonate, 4 parts of fluorite, 5 parts of wollastonite, oxide 5 parts of titanium, 3 parts of calcined talc; golden brown is 3wt% of the total mass of giant crystal particles; after mixing the ingredients according to the composition ratio, put them into the frit furnace to burn the frit, after the frit is burnt, water quench and dry Then crush the dry frit and dry particles according to the requirements, and the crushed particles range from 10 to 60, 60 to 120, and 120 to 200 meshes respectively.

[0114] Mix these different particle sizes according to a certain ratio, directly spread on the inkjet surface glaze, and fire it in a kiln, with or without throwing, to obtain a brick surface pattern with a good crystal flower effect on the glaze; or

[0115] Appropriately add bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com