Water-based ink with three-dimensional effect and preparation method of water-based ink

A three-dimensional, water-based technology, used in inks, household appliances, applications, etc., can solve the problems of difficult to control viscosity, difficult to write ink, etc., and achieve the effect of good adhesion, wide application and rich and changeable colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

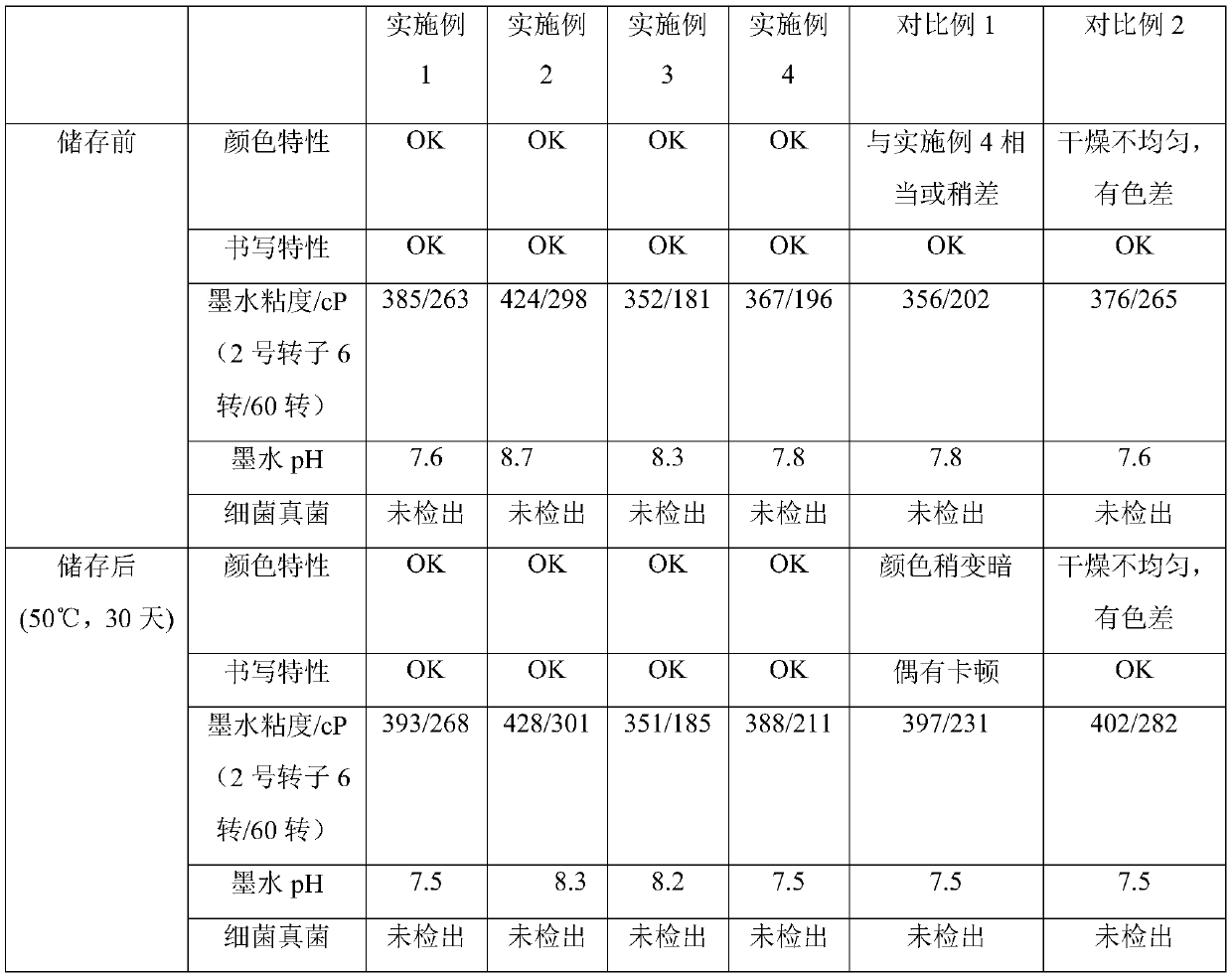

Examples

Embodiment 1

[0020] Mix 5g yellow pigment slurry, 0.5g green pigment slurry, 1g colored aluminum powder pigment and 5g deionized water and stir for 0.5h, then add 30g acrylic resin, 30g EVA resin and stir for 1h, then add 8g wetting agent (5g decaglycerin , 3g polyethylene glycol 300), 1g lubricant (dicarboxylic acid amide), 10g stabilizer (polyethylene wax) and stir for 1h under dry conditions, finally add 0.4g ammonia water to adjust the pH value, and add water to 100g. Stir for 0.5 hour, filter to remove large particles of impurities, and obtain the finished product.

Embodiment 2

[0022] Mix 2g of red pigment slurry, 2g of colored aluminum powder pigment and 5g of deionized water and stir for 0.5h, then add 20g of acrylic resin, 45g of EVA resin and stir for 1h, then add 10g of wetting agent (decaglycerol with a mass ratio of 1:1 Stir with polypropylene glycol 300), 1g lubricant (potassium oleate), 10g stabilizer (5g polyethylene wax, 5g fumed silica grinding solution) under dry conditions for 1h, finally add 0.2g ammonia water to adjust the pH value, add water to 100g. Stir for 0.5 hour, filter to remove large particles of impurities, and obtain the finished product.

Embodiment 3

[0024] Mix 5g blue pigment, 0.5g blue pigment slurry, 0.5g colored aluminum powder pigment and 10g deionized water and stir for 0.5h, then add 30g acrylic resin, 30g EVA resin and stir for 1h, then add 10g wetting agent (4g ten Polyglycerol (6g glycerin), 1.5g lubricant (phosphate ester), 8g stabilizer (2g decaglycerol oleate, 6g fumed silica grinding solution) were stirred for 1h under dry conditions, and finally 0.2g ammonia water was added to adjust the pH value , add water to 100g. Stir for 0.5 hour, filter to remove large particles of impurities, and obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com