Self-stabilized variable-slope high-performance prefabricated roof

A high-performance, self-stabilizing technology, used in roofs, buildings, building components, etc., can solve problems such as difficulty in controlling concrete compaction, difficulty in ensuring worker safety, and concrete slipping, enriching the sense of jumping and layering, and improving operations. Efficiency, the effect of reducing the use of scaffolding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

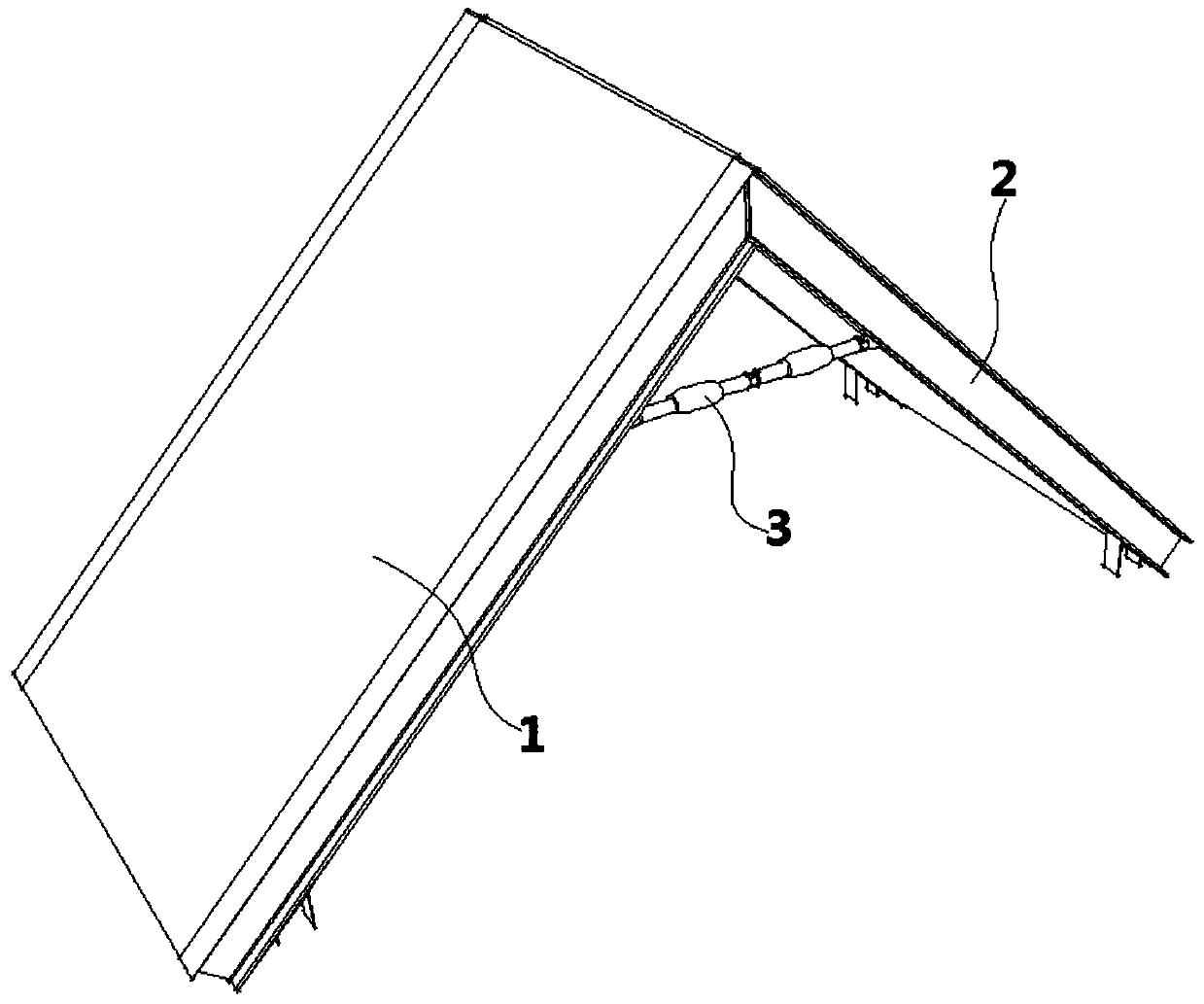

[0034] This embodiment discloses a self-stabilizing variable-slope high-performance prefabricated roof, which includes a roof panel I1, a roof panel II2 and an adjustment rod 3.

[0035] see Figure 7 , the roof panel I1 and the roof panel II2 are both oblique rectangular plates, and the upper edge of the roof panel I1 and the upper edge of the roof panel II2 are flexibly connected by a hinge structure. see figure 1 , the upper edges of the roof panels I1 and II2 are provided with grooves.

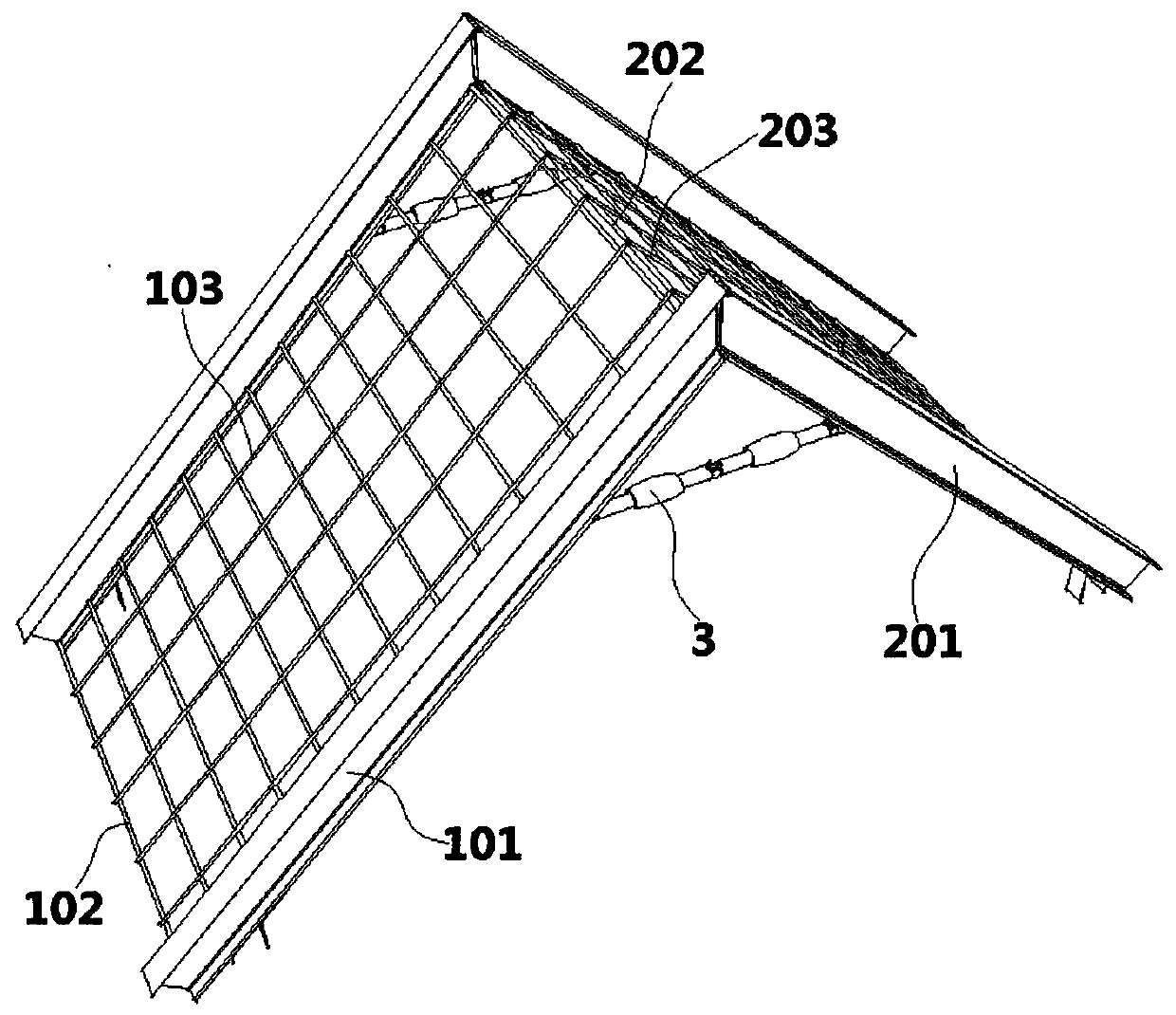

[0036] see figure 2 , the roof panel I1 includes edge-sealed steel beams I101 and steel mesh I, the two edge-sealed steel beams I101 are arranged obliquely and parallel to each other, and steel mesh I is welded between the two spaced edge-sealed steel beams I101 , fill concrete between two edge-sealed steel beams I101.

[0037] see figure 2, the roof panel II2 includes edge-banding steel beams II201 and steel mesh II, the two edge-banding steel beams II201 are arranged obliquely and...

Embodiment 2

[0061]This embodiment discloses a self-stabilizing variable-slope high-performance prefabricated roof, which includes a roof panel I1, a roof panel II2 and an adjustment rod 3.

[0062] see Figure 7 , the roof panel I1 and the roof panel II2 are both oblique rectangular plates, and the upper edge of the roof panel I1 and the upper edge of the roof panel II2 are flexibly connected by a hinge structure.

[0063] see figure 2 , the roof panel I1 includes edge-sealed steel beams I101 and steel mesh I, the two edge-sealed steel beams I101 are arranged obliquely and parallel to each other, and steel mesh I is welded between the two spaced edge-sealed steel beams I101 , fill concrete between two edge-sealed steel beams I101.

[0064] see figure 2 , the roof panel II2 includes edge-banding steel beams II201 and steel mesh II, the two edge-banding steel beams II201 are arranged obliquely and parallel to each other, and steel mesh II is welded between the two spaced apart edge-ban...

Embodiment 3

[0070] The main structure of this embodiment is the same as that of Embodiment 2, further, the edge-sealed steel beam I101 and the edge-sealed steel beam II201 are both I-beams.

[0071] see figure 2 , the reinforcement mesh I includes stress reinforcement I102 and distribution reinforcement I103, the stress reinforcement I102 is perpendicular to the edge-banding steel beam I101, and several stress reinforcement I102 are arranged at equal intervals along the length direction of the edge-banding steel beam I101, and the stress reinforcement The two ends of I102 are respectively welded to the upper surface of the lower flange of the two edge-sealed steel beams I101, and the two ends of the stressed steel bar I102 are respectively pressed against the webs of the two edge-sealed steel beams I101, and the uppermost stressed steel bar I102 is flush with the upper ends of the two edge-sealed steel beams I101, and the lowermost stressed steel bar I102 is flush with the lower ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com