Super-wear-resistant steel-ceramic composite wear-resistant lining plate and molding method thereof

A technology of composite wear-resistant liner and forming method, which is applied in the field of mineral processing in mines, can solve the problems of not reaching high hardness index, reducing wear resistance, and ceramic block fragmentation, etc., and achieves simple and convenient installation, good combination, The effect of material structure compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

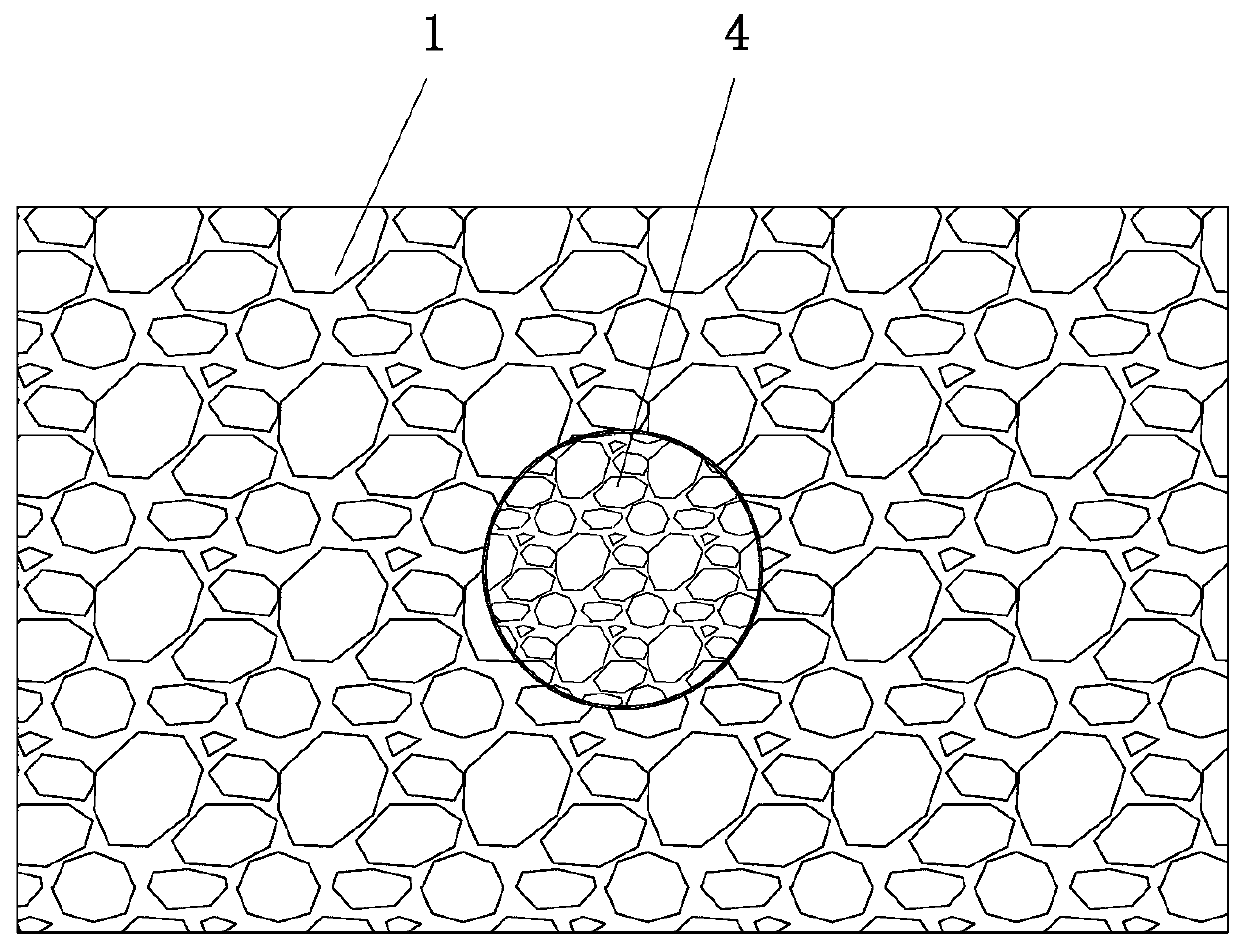

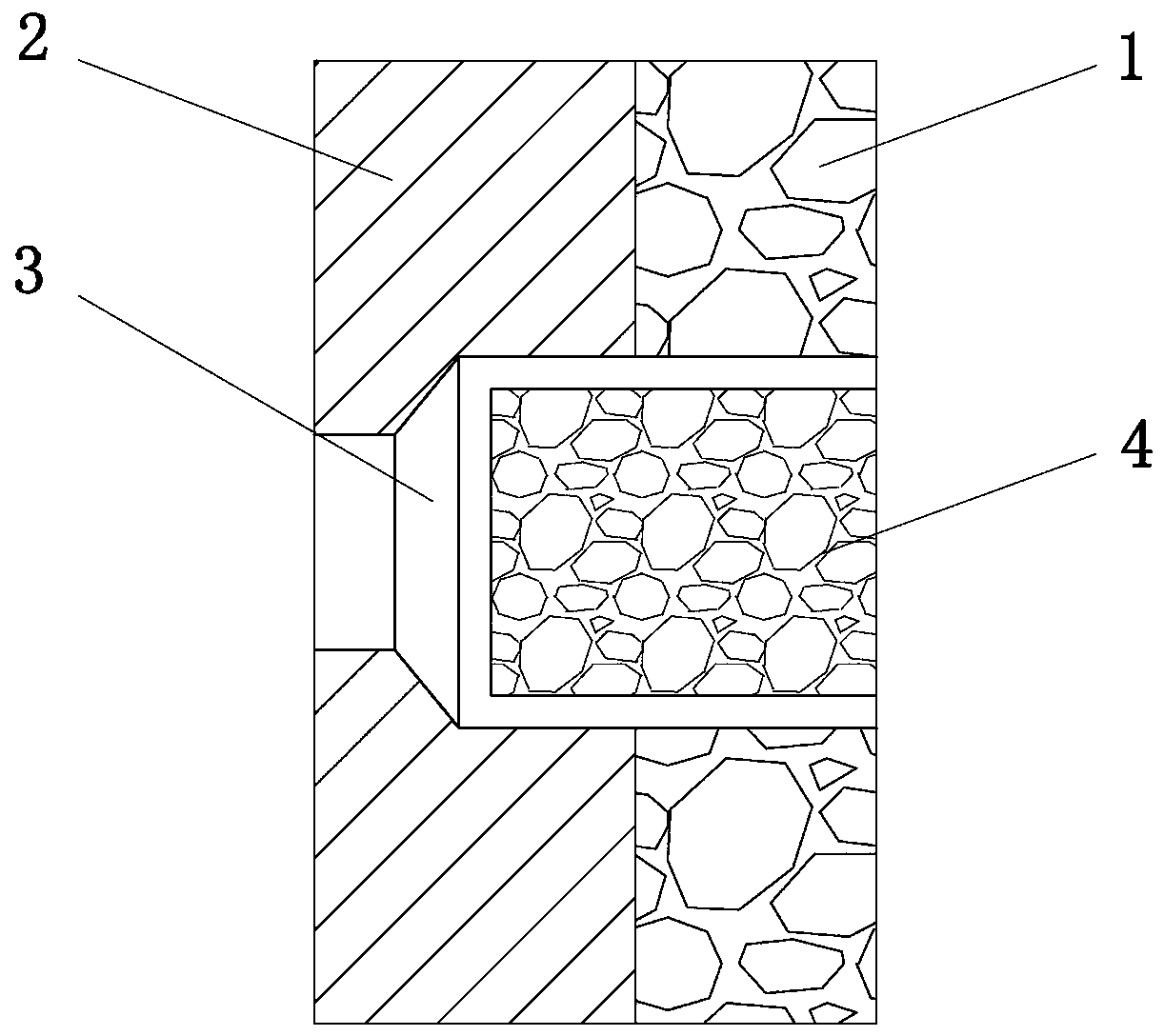

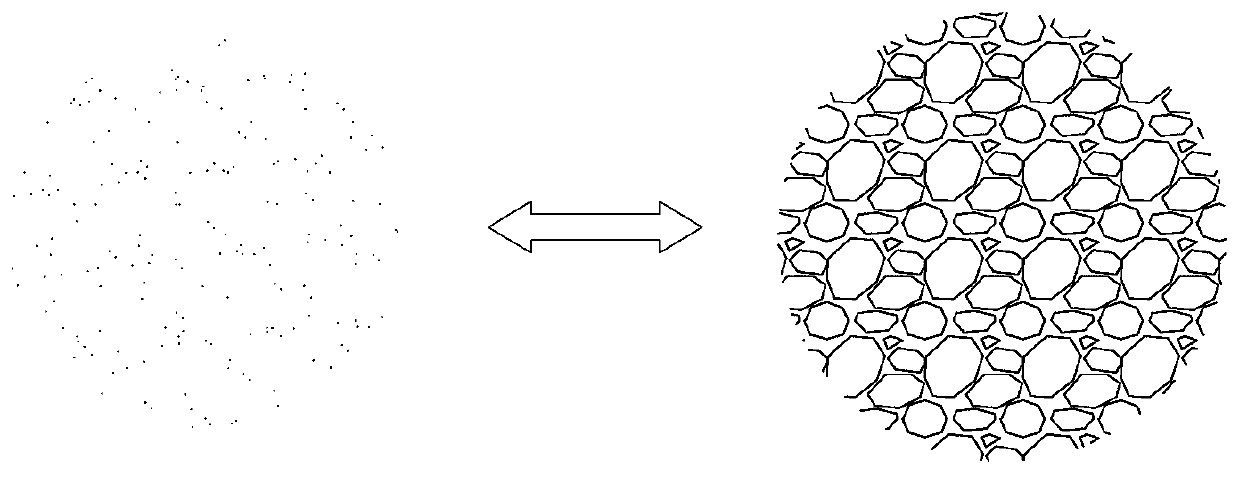

[0030] 1. Preparation of ZTA ceramic particles: ZTA ceramics are used for powder granulation, and the ceramic particles reach 50-80nm. Use an isostatic press to dry press the ceramic powder into blocks and pre-fire it at a temperature of 1150-1170°C. Then crush, screen the ZTA ceramic particles with a particle size of 1-3mm, and then sinter at a high temperature at a firing temperature of 1610-1630°C to obtain ZTA ceramic particles with irregular shapes, see image 3 .

[0031] 2. Detection of ZTA ceramic particles: The hardness of ZTA ceramic particles is measured by MH-5C microhardness tester, the bending strength is measured by three points with a span of 30mm (measured by bending method), and the fracture toughness KIC is measured by indentation method, as shown in the table below.

[0032] Physical and mechanical properties of ZTA ceramics

[0033]

[0034] 3. Prepare the honeycomb ceramic prefabricated body: mix ZTA ceramic particles with a high-temperature-resistan...

Embodiment 2

[0042] 1. Preparation of ZTA ceramic particles: ZTA ceramics are used for powder granulation, and the ceramic particles reach 60-100nm. Use an isostatic press to dry-press the ceramic powder into blocks and pre-fire it at a temperature of 1140-1165°C. Then crush, screen the ZTA ceramic particles with a particle size of 1-3mm, and then sinter at a high temperature at a firing temperature of 1630-1645°C to obtain ZTA ceramic particles with irregular shapes. See image 3 .

[0043] 2. Detection of ZTA ceramic particles: The hardness of ZTA ceramic particles is measured by MH-5C microhardness tester, the bending strength is measured by three points with a span of 30mm (measured by bending method), and the fracture toughness KIC is measured by indentation method, as shown in the table below.

[0044] Physical and mechanical properties of ZTA ceramics

[0045]

[0046] 3. Prepare the honeycomb ceramic prefabricated body: mix ZTA ceramic particles with a high-temperature-resista...

Embodiment 3

[0054] 1. Preparation of ZTA ceramic particles: ZTA ceramics are used to powder and granulate, and the ceramic particles reach 75-115nm. Use an isostatic press to dry press the ceramic powder into blocks and pre-fire it at a temperature of 1170-1195°C. Then crush, screen the ZTA ceramic particles with a particle size of 1-3mm, and then sinter at a high temperature at a firing temperature of 1625-1640°C to obtain ZTA ceramic particles with irregular shapes. See image 3 .

[0055] 2. Detection of ZTA ceramic particles: The hardness of ZTA ceramic particles is measured by MH-5C microhardness tester, the bending strength is measured by three points with a span of 30mm (measured by bending method), and the fracture toughness KIC is measured by indentation method, as shown in the table below.

[0056] Physical and mechanical properties of ZTA ceramics

[0057]

[0058] 3. Prepare the honeycomb ceramic prefabricated body: mix ZTA ceramic particles with a high-temperature-resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com