Integral material for laying ground

An integral material and ground technology, applied in the field of integral materials, can solve the problems of filth storage, rough terrazzo floor, dullness and other problems, and achieve the effect of saving resources, long service life and good comprehensive performance.

Inactive Publication Date: 2018-05-15

江门市卡斯乐建材有限公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, traditional construction techniques usually result in very rough terrazzo floors, filth, and even cracks and shrinkage joints on the floor, which seriously hinder daily hygiene and cleaning

Over time, terrazzo has encountered very prominent problems in practical use: stained, dull

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

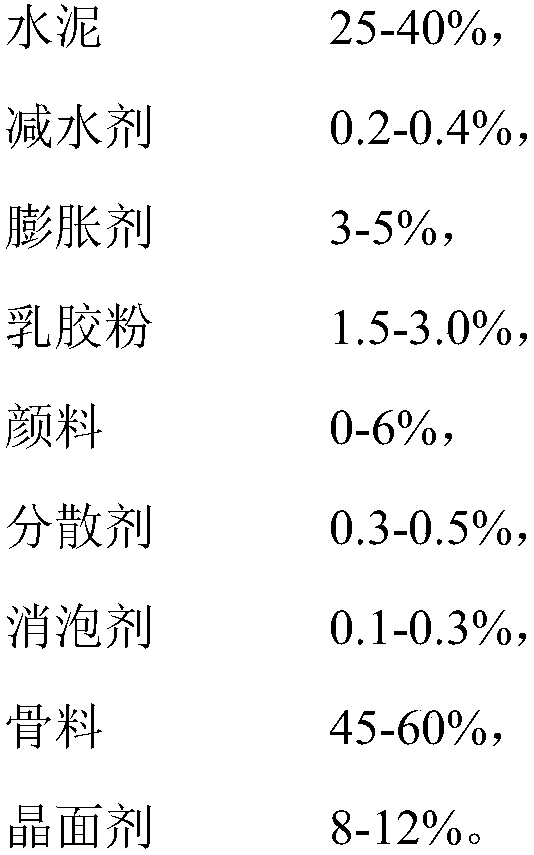

[0028] A monolithic material for flooring comprising the following components by weight percentage:

[0029]

Embodiment 2

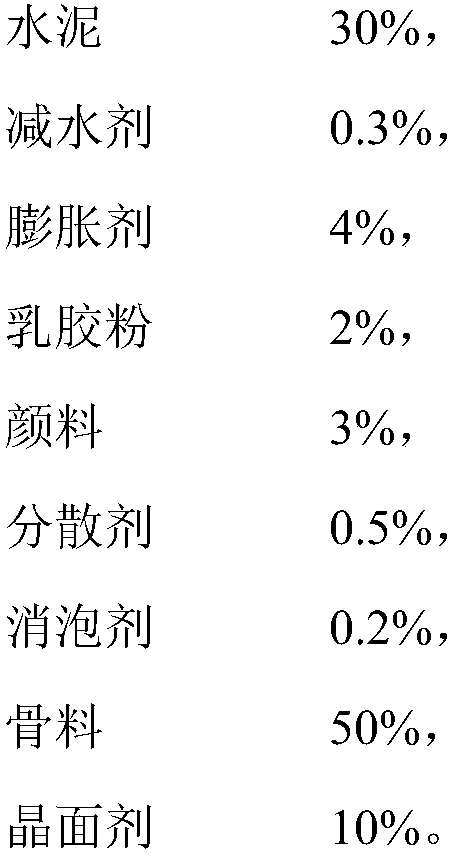

[0031] A monolithic material for flooring comprising the following components by weight percentage:

[0032]

Embodiment 3

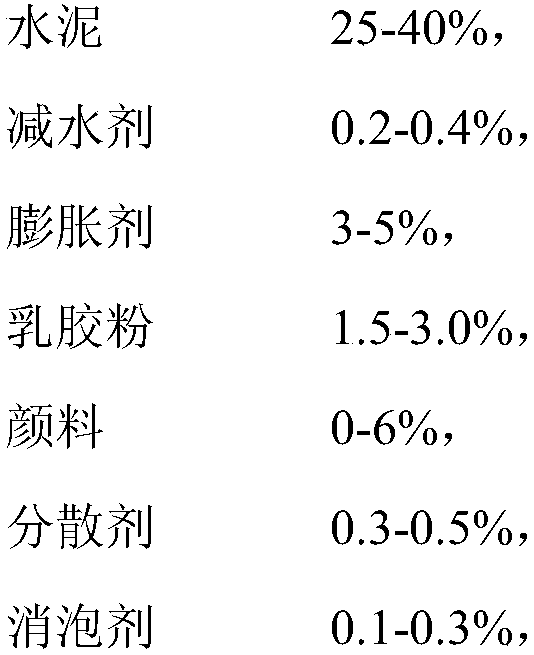

[0034] A monolithic material for flooring comprising the following components by weight percentage:

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an integral material for laying a ground. The integral material comprises cement, water reducing agents, expanding agents, latex powder, pigments, dispersing agents, defoamingagents, aggregates, crystal plane agents and the like. The integral material takes the cement, the aggregates and the crystal plane agents as main raw materials and takes the water reducing agents, the expanding agents, the latex powder, the pigments, the dispersing agents, the defoaming agents and the like as auxiliary materials, and the produced integral material is good in comprehensive performance, has super-abrasion resistance, decorativeness and corrosion resistance and does not release a VOC (volatile organic compound). According to the integral material, the aggregates are provided with renewable components, waste resources can be reused, resources can be saved, and energy conservation and emission reduction are achieved. Compared with a traditional terrazzo, the integral materialhas longer service life, and the service life of the integral material can reach 20 years.

Description

technical field [0001] The invention relates to a monolithic material for floor coverings. Background technique [0002] Traditional terrazzo has a huge market in China due to its unique advantages such as low cost, optional color mosaic, and convenient construction. There are more than one billion square meters of terrazzo floors used in various buildings in urban and rural areas across the country. [0003] However, traditional construction techniques usually result in very rough terrazzo floors, filth, and even floor cracks and shrinkage joints, which seriously hinder daily sanitation and cleaning. Over time, terrazzo has encountered very prominent problems in actual use: stained and dull. How to restore the weathered and eroded terrazzo to its original bright and beautiful aesthetic feeling is an urgent problem to be solved in the architectural decoration industry. [0004] At present, the new concept of "ultra-energy-saving ecological environmental protection overall...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B111/60C04B111/20

CPCC04B28/04C04B2111/20C04B2111/2038C04B2111/60C04B24/223C04B2103/0068C04B24/2623C04B2103/54C04B2103/408C04B2103/50C04B14/06C04B24/282C04B14/22C04B24/226

Inventor 李栋辉

Owner 江门市卡斯乐建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com