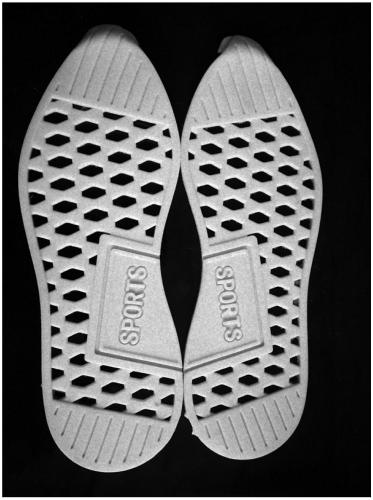

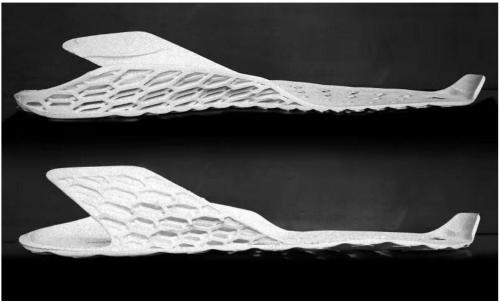

Wear-resistant rubber particle capable of being formed by injection molding, preparation method and application thereof

A technology of rubber particles and EPDM rubber, which is applied in applications, shoe soles, clothing, etc., can solve the problems of wear resistance, anti-skid and lack of elasticity, increased consumables, increased operating procedures, etc., and achieves obvious advantages in wear resistance , The production process is simple, the effect of high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

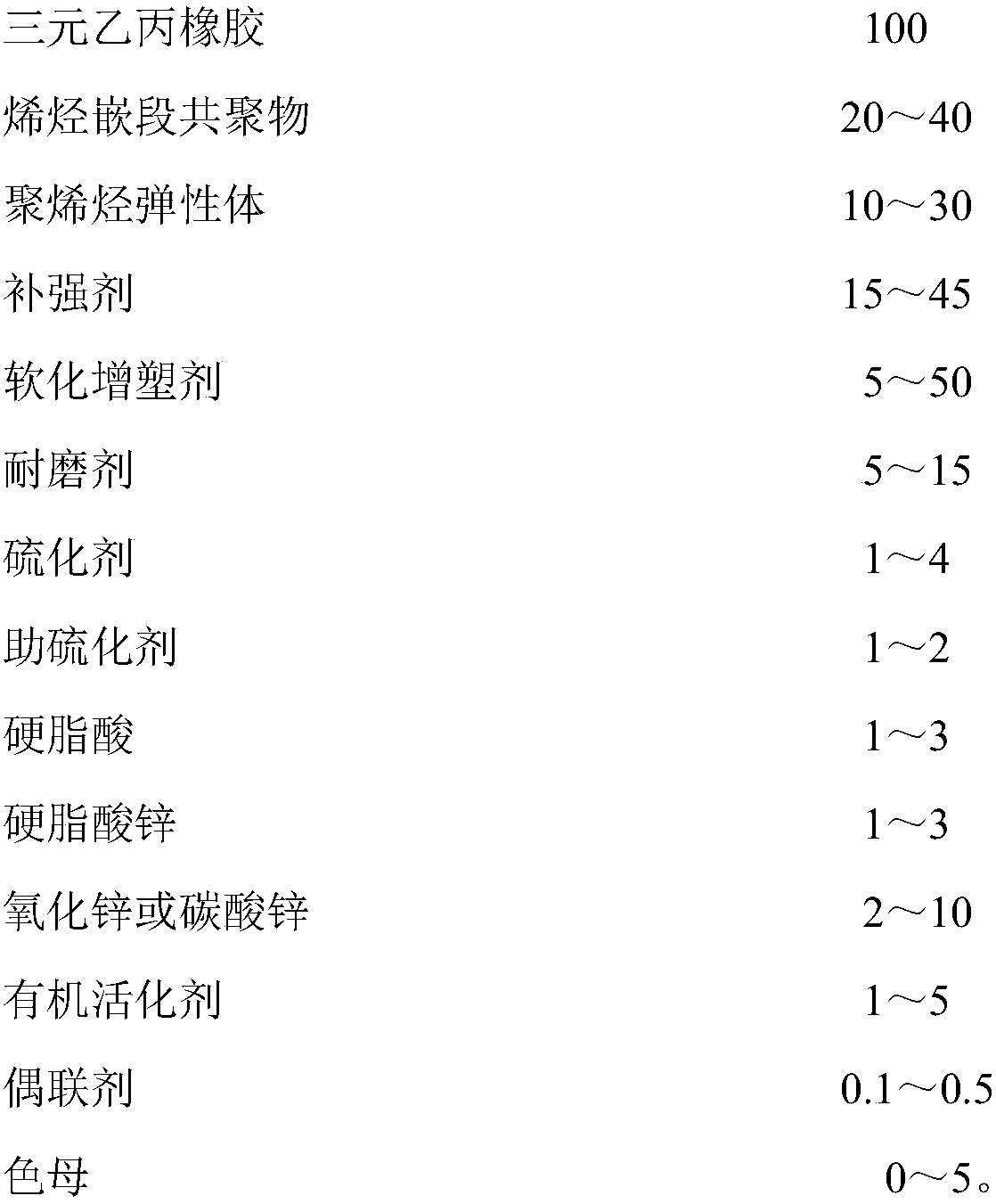

[0035] The formulation of the injection moldable and wear-resistant rubber particles provided in this example is shown in Table 1.

[0036] The preparation method of injection moldable and wear-resistant rubber particles described in this embodiment comprises the following steps:

[0037] a) After mixing the formulated amount of EPDM rubber with a reinforcing agent, an organic activator, a coupling agent and a softening plasticizer, carry out a coupling reinforcement mixing treatment at 120-145°C for 15-30 minutes;

[0038] b) Combine the sizing material after the coupling reinforcement kneading treatment in step a) with a formula amount of olefin block copolymer, polyolefin elastomer, wear-resistant agent, stearic acid, zinc stearate, zinc oxide or zinc carbonate After mixing with the color masterbatch, carry out plasticizing and banburying treatment at 135-150°C for 20-40 minutes;

[0039] c) mixing the compounded rubber after the plasticizing and banburying treatment in st...

Embodiment 2~5

[0043] The formulations of the injection moldable and wear-resistant rubber particles provided in Examples 2-5 are shown in Table 1.

[0044] The preparation methods of injection moldable and wear-resistant rubber particles described in Examples 2-5 are the same as those described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com