External thermal-insulation environment-friendly composite polyether for delivering high-temperature media and preparation method thereof

A technology for combining polyether and high-temperature medium is applied in the field of environment-friendly combined polyether for external insulation of pipelines conveying high-temperature medium and its preparation, which can solve the problem of reduced thermal insulation performance of polyurethane foam, increased thermal conductivity of polyurethane foam, and high thermal conductivity and high thermal conductivity. Compressive strength reduction and other problems, to achieve the effect of improving aging resistance, improving high temperature oxidation resistance, and the preparation method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

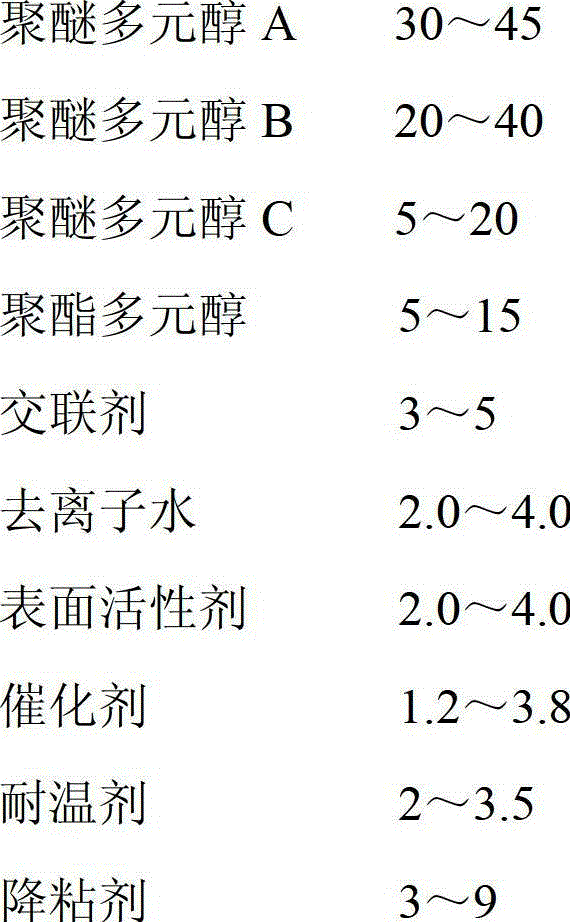

[0025] Prepare an environment-friendly composite polyether for external insulation of pipelines conveying high-temperature medium in the reaction vessel: put each raw material into the reaction kettle according to the following feeding ratio, stir at room temperature for 1 hour, take samples for inspection, and obtain the combination if it meets the index requirements Polyether, taken out from the reactor and put into barrels for storage.

[0026]

Embodiment 2

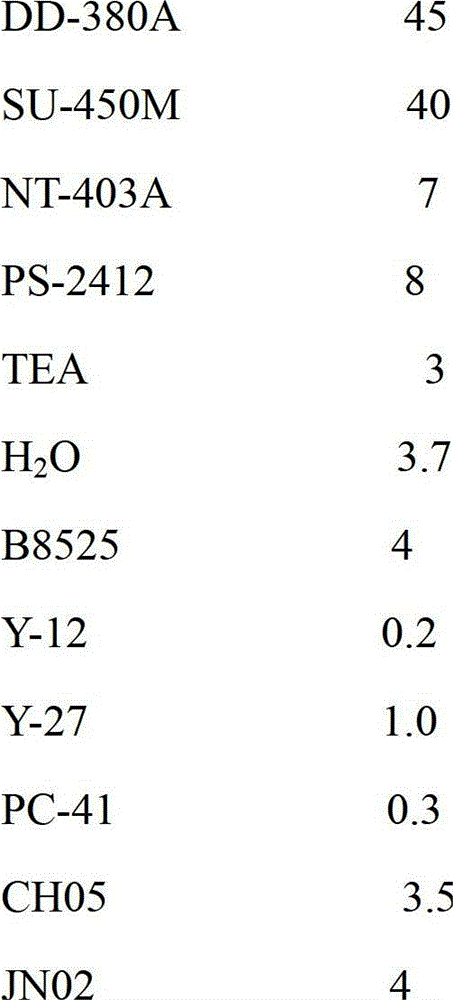

[0028] Prepare an environment-friendly composite polyether for external insulation of pipelines conveying high-temperature medium in the reaction vessel: put each raw material into the reaction kettle according to the following feeding ratio, stir at room temperature for 1.2 hours, take samples for inspection, and obtain the combination if it meets the index requirements Polyether, taken out from the reactor and put into barrels for storage.

[0029]

[0030]

Embodiment 3

[0032] Prepare an environment-friendly composite polyether for external insulation of pipelines conveying high-temperature medium in the reaction vessel: put each raw material into the reaction kettle according to the following feeding ratio, stir at room temperature for 1.5 hours, take samples for inspection, and obtain the combination if it meets the index requirements Polyether, taken out from the reactor and put into barrels for storage.

[0033]

[0034] The environment-friendly combined polyether and PM200 prepared in the above examples for external heat preservation of high-temperature medium pipelines were mixed and foamed by a high-pressure foaming machine at a ratio of 100:150. After the foam was matured for 24 hours, the various parameters of the foam were tested. Performance, detailed data are shown in Table 1:

[0035] Table 1 Properties of the foam

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com