Plate joint treatment method for autoclaved aerated concrete external wall plates

A technology of autoclaved gas filling and processing method, which is applied to the processing of building materials, building components, building insulation materials, etc. It can solve the problems of large amount of filled organic glue, complicated maintenance in the later period, and high technical requirements, so as to avoid filling incompletely , compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for treating the joints of an autoclaved aerated concrete exterior wall panel, the method comprising the following steps:

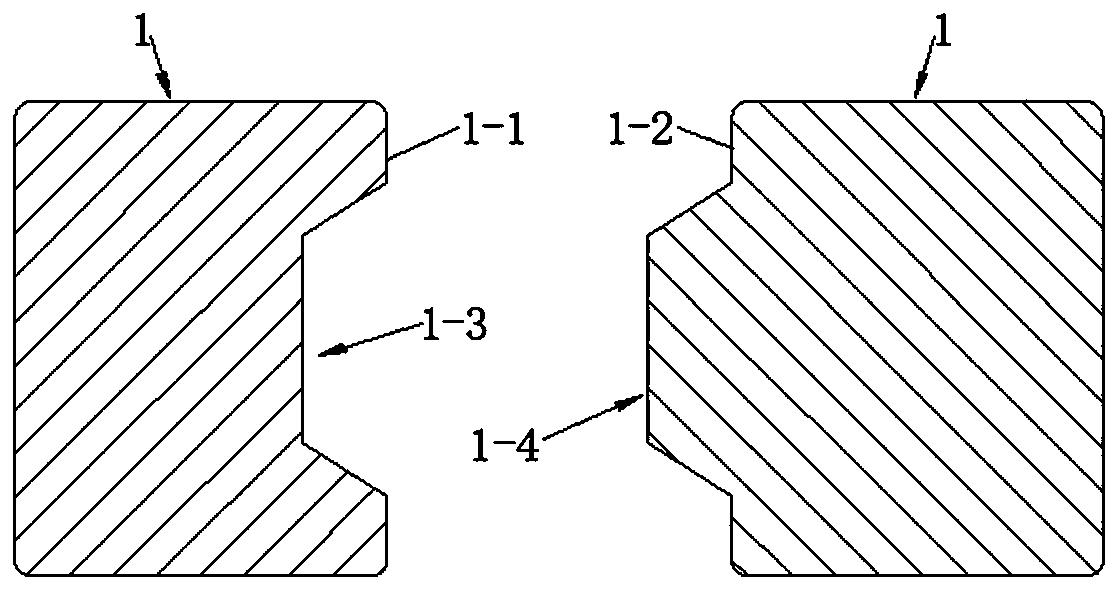

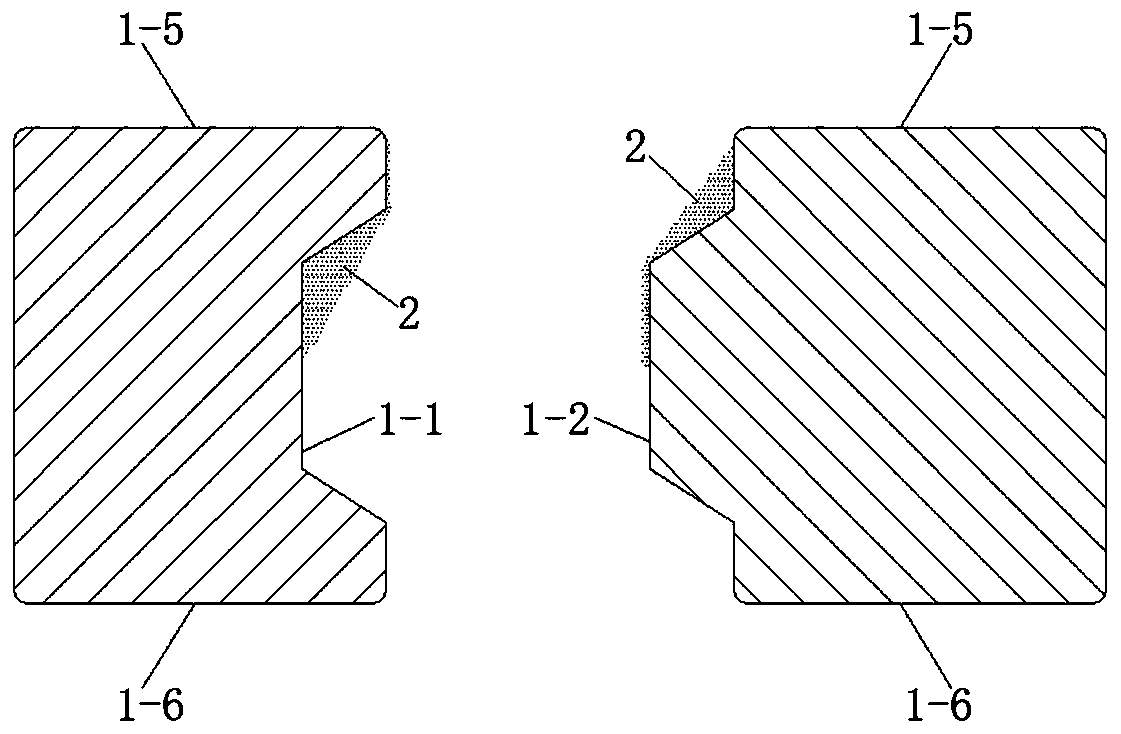

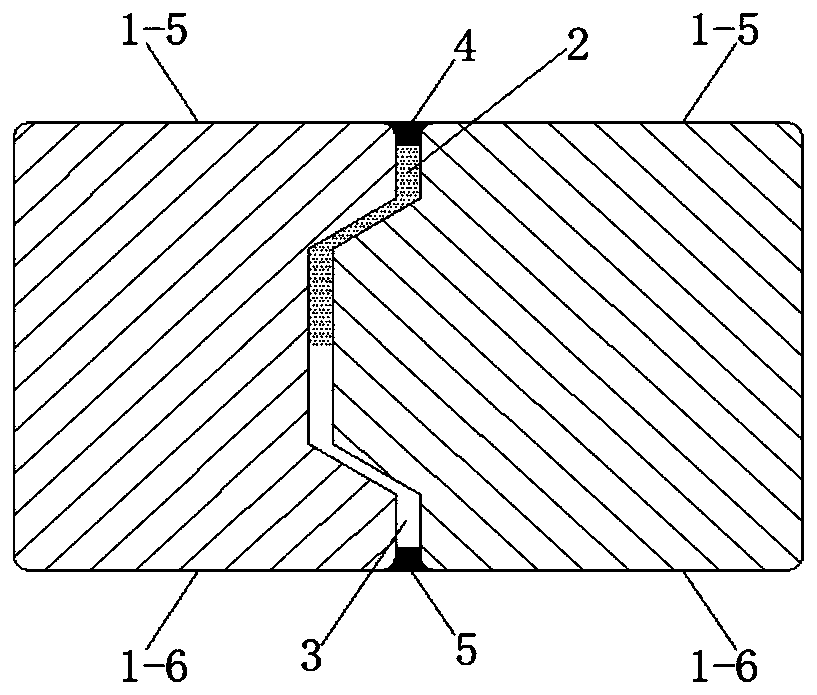

[0038] S0, such as figure 1 As shown, grooves 1-3 are provided on the side wall of one of the autoclaved aerated concrete outer wall panels 1 along its length direction in advance to form the second autoclaved aerated concrete outer wall panel 1 to be spliced. A splicing surface 1-1; on the side wall of another autoclaved aerated concrete exterior wall panel 1, a protrusion 1-4 for clamping with the groove 1-3 is provided to form a second splicing surface 1-2 . The advantage of such setting is: on the one hand, the curved surface of the groove 1-3 and the protrusion 1-4 can be used to extend the path of moisture migration along the thickness direction of the autoclaved aerated concrete exterior wall panel 1, thereby slowing down the moisture migration On the other hand, when splicing, the construction personnel o...

Embodiment 2

[0049] The steps and principles of the method for treating the joints of the autoclaved aerated concrete exterior wall panels in this embodiment are the same as those in Embodiment 1, and will not be repeated in this embodiment.

[0050] The difference is that there are multiple grooves 1-3 in this embodiment, and the multiple grooves 1-3 are sequentially arranged along the thickness direction of the autoclaved aerated concrete exterior wall panel 1 . Since the protrusions 1-4 are arranged in one-to-one correspondence with the grooves 1-3, the number of the protrusions 1-4 is the same as that of the grooves 1-3, and it is also along the thickness direction of the corresponding autoclaved aerated concrete exterior wall panel 1 Set in turn.

[0051] For example, if Figure 4 As shown, two grooves 1-3 are opened on the side wall of one of the autoclaved aerated concrete outer wall panels 1, and two protrusions 1 are opened on the side wall of the other autoclaved aerated concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com