Medium for roof greening

A roof greening and medium technology, applied in horticulture, botany equipment and methods, container cultivation, etc., can solve the problems of high construction and maintenance costs, high construction technology requirements, and difficulties in promotion and implementation, and achieve low production costs, Easy construction and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

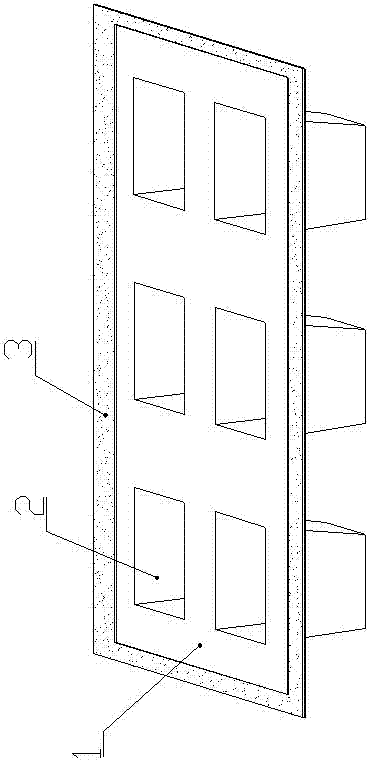

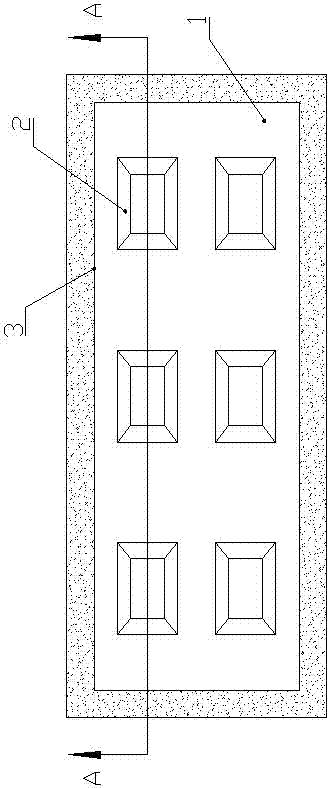

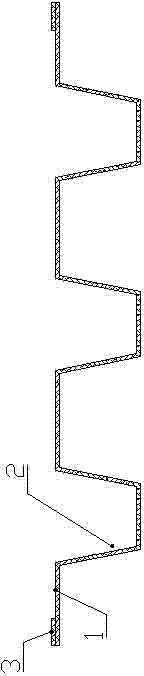

[0021] Such as figure 1 , figure 2 and image 3 Shown, a kind of medium that is used for roof greening, comprises medium main body, and described medium main body comprises matrix 1, and described matrix 1 is made of waste polyester mesh and has the porosity of 20-30% mesh structure, the middle part of the base 1 is provided with a group of pits 2 which are integrally heat-sealed and stamped by the base 1 and protrude to the lower side of the base 1. The pits 2 are structures whose inner diameter gradually decreases from top to bottom. Article 3.

[0022] When the present invention is in use, the pit is placed on the roof with the mouth facing upwards, then the pit is filled with a substrate, and the required plants are planted in the substrate, and on-site splicing is carried out according to construction requirements, or on-site movement is carried out according to maintenance requirements. The construction and maintenance management are convenient and quick. The matrix ...

Embodiment 2

[0024] Such as figure 1 , figure 2 and image 3 Shown, a kind of medium that is used for roof greening, comprises medium main body, and described medium main body comprises matrix 1, and described matrix 1 is made of waste polyester mesh and has the porosity of 20-30% mesh structure, the middle part of the base 1 is provided with a group of pits 2 which are integrally heat-sealed and stamped by the base 1 and protrude to the lower side of the base 1. The pits 2 are structures whose inner diameter gradually decreases from top to bottom. Article 3.

[0025] The thickness of the base body 1 is 1-2mm.

[0026] The pits 2 are distributed equidistantly in a row or in a honeycomb shape in the middle of the base body 1 .

[0027] The cross section of the pit 2 is circular or square or regular polygonal, the longitudinal section of the pit 2 is a trapezoidal structure, and the angle between the side wall of the pit 2 and the vertical plane is 10°-15°. °.

[0028] The depth of th...

Embodiment 3

[0034] Such as figure 1 , figure 2 and image 3 Shown, a kind of medium that is used for roof greening, comprises medium main body, and described medium main body comprises matrix 1, and described matrix 1 is made of waste polyester mesh and has the porosity of 20-30% mesh structure, the middle part of the base 1 is provided with a group of pits 2 which are integrally heat-sealed and stamped by the base 1 and protrude to the lower side of the base 1. The pits 2 are structures whose inner diameter gradually decreases from top to bottom. Article 3.

[0035] The thickness of the base body 1 is 1-2mm.

[0036] The pits 2 are distributed equidistantly in a row or in a honeycomb shape in the middle of the base body 1 .

[0037] The cross section of the pit 2 is circular or square or regular polygonal, the longitudinal section of the pit 2 is a trapezoidal structure, and the angle between the side wall of the pit 2 and the vertical plane is 10°-15°. °.

[0038] The depth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com