Anti-aging asphalt for muck truck road and preparation method of anti-aging asphalt

An anti-aging, muck truck technology, applied in the field of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

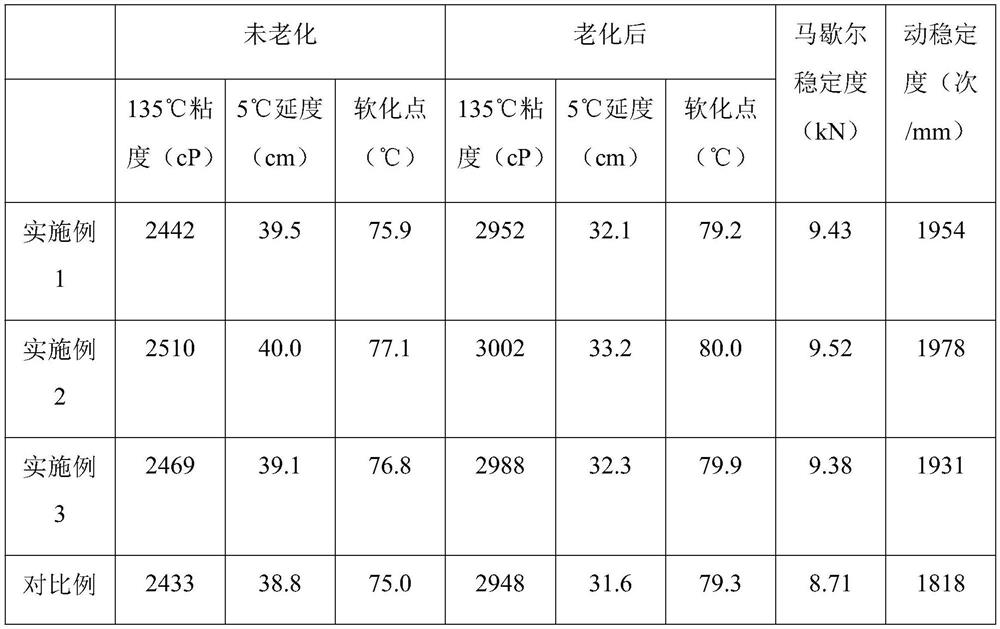

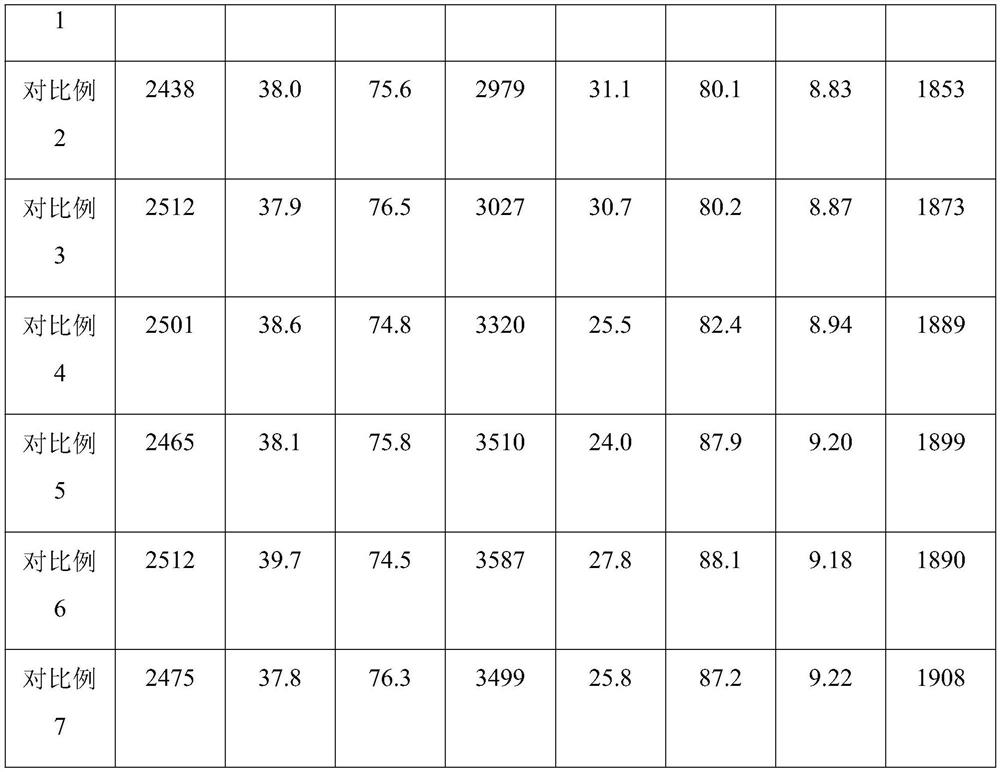

Embodiment 1

[0033] A preparation method of aging-resistant asphalt for muck truck roads, the preparation method of aging-resistant asphalt for muck truck roads mainly comprises the following preparation steps:

[0034] (1) Mix the foamed asphalt, ferric oxide and deionized water in a mass ratio of 1:0.1:1, stir evenly, heat at 200rpm and 600W for 60min, recover ferric oxide with a magnet, filter, and dry at room temperature Heat-treated foamed asphalt was obtained for 8 hours; the heat-treated foamed asphalt was placed in an oxygen-nitrogen mixed atmosphere, and the mass ratio of oxygen and nitrogen in the oxygen-nitrogen mixed atmosphere was 1:4, and oxidized at 68 °C for 6 hours to obtain oxidized foamed asphalt;

[0035] (2) Mix the oxidized foamed asphalt, potassium carbonate and N,N-dimethylacetamide in a mass ratio of 1:3:10, and after stirring for 46 minutes at 100 rpm, add 1,2,3- Tribromopropane, react at 70°C for 26 hours, add polyether glycol with 2.0 times the mass of oxidized ...

Embodiment 2

[0043] A preparation method of aging-resistant asphalt for muck truck roads, the preparation method of aging-resistant asphalt for muck truck roads mainly comprises the following preparation steps:

[0044] (1) Mix the foamed asphalt, ferric oxide and deionized water in a mass ratio of 1:0.25:3, stir evenly, heat at 250rpm and 700W for 52min, recover ferric oxide with a magnet, filter, and dry at room temperature Heat-treated foamed asphalt was obtained for 10 hours; the heat-treated foamed asphalt was placed in an oxygen-nitrogen mixed atmosphere, and the mass ratio of oxygen and nitrogen in the oxygen-nitrogen mixed atmosphere was 1:10, and oxidized at 75 °C for 4 hours to obtain oxidized foamed asphalt;

[0045] (2) Mix the oxidized foamed asphalt, potassium carbonate, and N,N-dimethylacetamide in a mass ratio of 1:3:12.5, and after stirring for 38 minutes at 150 rpm, add 1,2,3- Tribromopropane, react at 79°C for 24 hours, add polyether glycol with 2.7 times the mass of the...

Embodiment 3

[0053] A preparation method of aging-resistant asphalt for muck truck roads, the preparation method of aging-resistant asphalt for muck truck roads mainly comprises the following preparation steps:

[0054] (1) Mix the foamed pitch, ferric oxide and deionized water in a mass ratio of 1:0.4:5, stir evenly, heat at 300rpm and 800W for 44min, recover ferric oxide with a magnet, filter, and dry at room temperature Heat-treated foamed asphalt was obtained in 12 hours; the heat-treated foamed asphalt was placed in an oxygen-nitrogen mixed atmosphere, and the mass ratio of oxygen and nitrogen in the oxygen-nitrogen mixed atmosphere was 1:16, and oxidized at 82 °C for 2 hours to obtain oxidized foamed asphalt;

[0055] (2) Mix the oxidized foamed asphalt, potassium carbonate, and N,N-dimethylacetamide in a mass ratio of 1:3:15, and after stirring for 30 minutes at 200 rpm, add 1,2,3- 2.8 times the mass of the oxidized foamed asphalt. Tribromopropane, react at 88°C for 22 hours, add po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com