A kind of anti-aging high barrier solar panel back film and preparation method thereof

A solar cell, high-barrier technology, used in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of yellowing, embrittlement and aging of the back film, affecting the long-term power generation performance of modules, and achieve good heat resistance and enhanced heat resistance. durability, improved service life, and durable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of anti-aging high barrier solar cell panel back film 1, it comprises the steps:

[0041] S100 Provide a base layer 30, and bond the anti-ultraviolet layer 20 on the outer surface of the base layer 30. The material composition of the anti-ultraviolet layer 20 is 10-15 parts by weight of polytrimethylene terephthalate, 40- 50 parts of polyimide, 8-10 parts of vinyl triisopropenyloxysilane, 5-8 parts of carboxymethyl cellulose, 6-10 parts of nano-cerium dioxide and 2-3 parts of antioxidant;

[0042] S200 bonding the bonding layer 40 on the inner surface of the base layer 30, the bonding layer 40 is made of polyurethane resin, diphenyldimethoxysilane, organic peroxide, polybutylene terephthalate , octadecyl acrylate, isocyanate curing agent and ethanol solvent;

[0043] S300 bonding the weather-resistant layer 10 to the outer surface of the UV-resistant layer 20, bonding the weather-resistant layer 10, the UV-resistant layer, the base layer 30 and the...

Embodiment 1

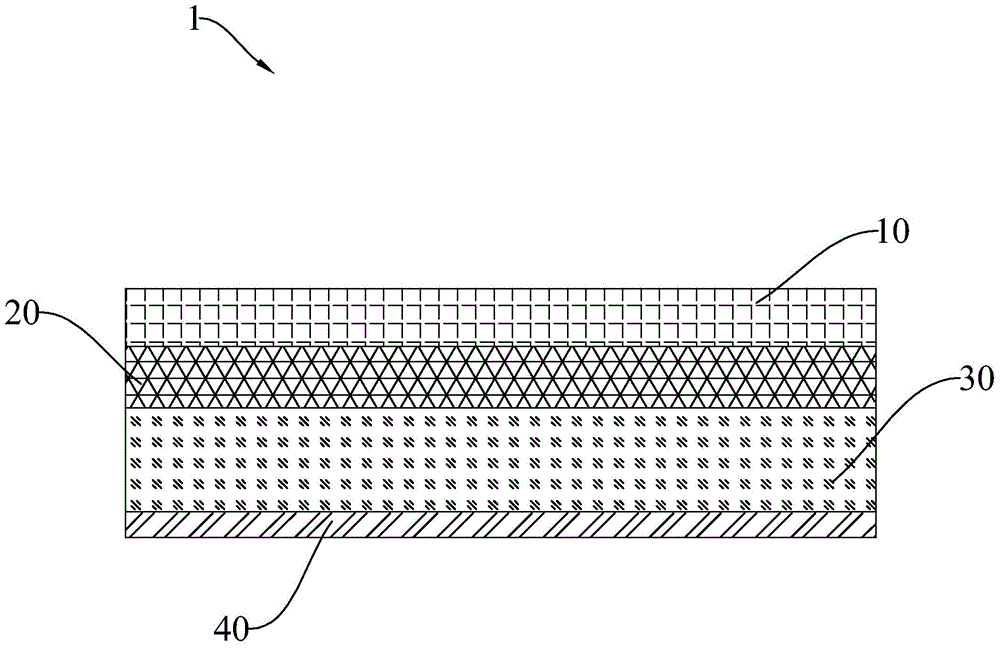

[0053] Technical solution of the present invention: an anti-aging high-barrier solar panel back film 1, including a four-layer structure from outside to inside, the first layer is a weather-resistant layer 10, the second layer is an anti-ultraviolet layer 20, and the third layer is a base layer 30. The fourth layer is an adhesive layer 40, the first layer and the second layer, the second layer and the third layer, and the third layer and the fourth layer are connected by glue.

[0054] The first layer is a weather-resistant layer 10 with a thickness of 56 μm and consists of the following components in parts by mass:

[0055] 34 parts polyimide

[0056] 13 parts of polyoxymethylene

[0057] Aluminum hexafluoro-2,4-pentanedione 6 parts

[0058] 8 parts of trifluoropropylmethylcyclotrisiloxane

[0059] Vinyltriethoxysilane 6 parts

[0060] Ethylene-vinyl acetate copolymer 7 parts

[0061] 6 parts polyvinyl alcohol

[0062] Nano silicon dioxide 4 parts

[0063] 3 parts isoc...

Embodiment 2

[0092] Technical solution of the present invention: an anti-aging high-barrier solar cell panel back film 1, including a four-layer structure from outside to inside, the first layer is a weather-resistant layer 10, the second layer is an anti-ultraviolet layer 20, and the third layer is a PET layer , the fourth layer is an adhesive layer 40, the first layer and the second layer, the second layer and the third layer, and the third layer and the fourth layer are connected by adhesive.

[0093] The first layer is the weather-resistant layer 10 with a thickness of 50-80 μm and consists of the following components in parts by mass:

[0094] Polyimide 40 parts

[0095] 18 parts of polyoxymethylene

[0096] Aluminum hexafluoro-2,4-pentanedione 6 parts

[0097] 12 parts of trifluoropropylmethylcyclotrisiloxane

[0098] Vinyltriethoxysilane 8 parts

[0099] Ethylene-vinyl acetate copolymer 8 parts

[0100] 5 parts polyvinyl alcohol

[0101] Nano silicon dioxide 4 parts

[0102] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com