Preparation process of steel belt reinforced spiral corrugated pipe

A spiral corrugated pipe and preparation process technology, applied in coating, organic chemistry, etc., can solve the problems of not meeting the high-performance anti-aging requirements, high-density polyethylene is easy to age, poor mechanical properties and easy to deform, etc., to improve antistatic Uniform performance and anti-oxidation performance, antistatic performance and aging resistance, anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The concrete preparation process of unsaturated antioxidant is as follows:

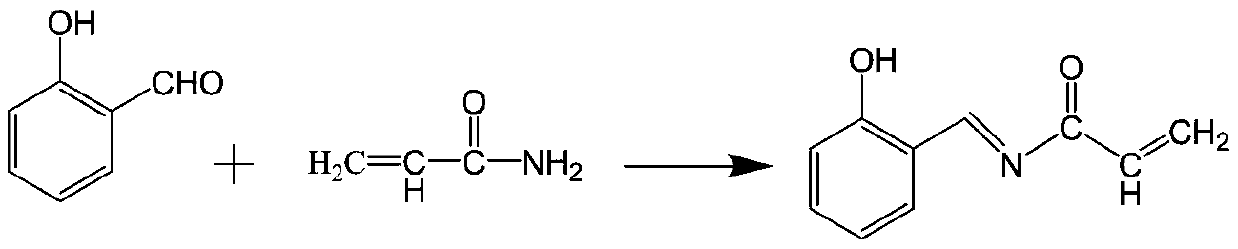

[0022] ①Add 7.1g of acrylamide to 200mL of ether and stir to dissolve, then add 12.2g of salicylaldehyde to it, raise the temperature to 60-65°C, stir and react for 5-6h, then cool down to room temperature, filter, wash and dry to obtain product A, The reaction structure is as follows;

[0023]

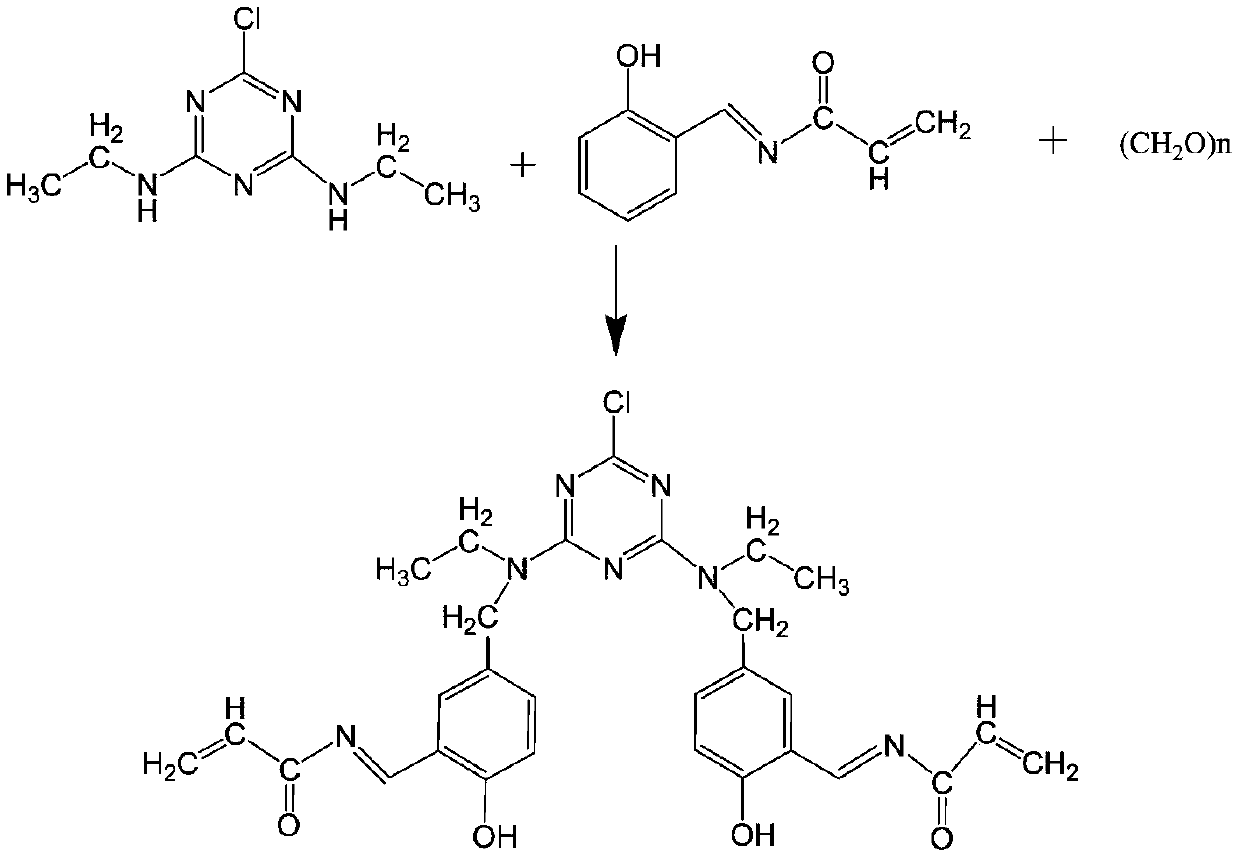

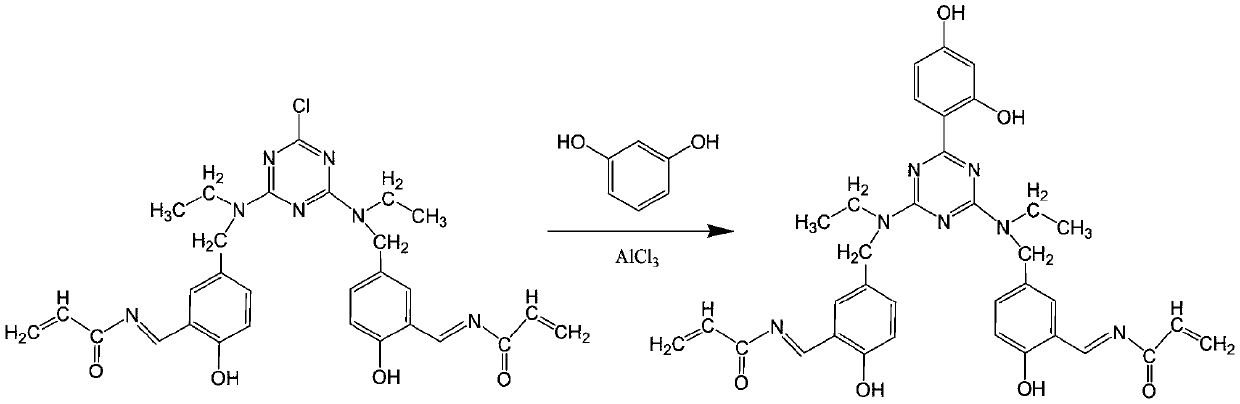

[0024]②Put 12mL of concentrated hydrochloric acid, 8g of paraformaldehyde and 150mL of dioxane into the reaction kettle at the same time, then add 10g of product A into it, stir and mix for 3-5min, then add 4.7g of 2-chloro-4 , 6-bis(ethylamino)-1,3,5-triazine, keep the amount of each addition at 100-150mg, the interval between each addition is 10-12min, after the addition is complete, control the temperature and stir React for 40-45h, then heat up to 50-60°C and reflux for 8-10h, then evaporate to remove the solvent, then wash the evaporated product with 5% sodium hydroxide solution and deionized ...

Embodiment 2

[0029] The concrete preparation process of unsaturated antioxidant is as follows:

[0030] ①Add 7.1g of acrylamide to 200mL of ether and stir to dissolve, then add 12.2g of salicylaldehyde to it, raise the temperature to 60-65°C, stir and react for 5-6h, then cool down to room temperature, filter, wash and dry to obtain product A;

[0031] ②Put 12mL of concentrated hydrochloric acid, 8g of paraformaldehyde and 150mL of dioxane into the reaction kettle at the same time, then add 4.8g of product A into it, stir and mix for 3-5min, then add 4.7g of 2-chloro- For 4,6-bis(ethylamino)-1,3,5-triazine, keep the amount of each addition at 100-150mg, and the interval between each addition is 10-12min. After the addition is complete, control the temperature to remain unchanged Stir the reaction for 40-45h, then heat up to 50-60°C and reflux for 8-10h, then evaporate to remove the solvent, and then wash the evaporated product with 5% sodium hydroxide solution and deionized to medium Afte...

Embodiment 3

[0034] The concrete preparation process of unsaturated antioxidant is as follows:

[0035] ①Add 7.1g of acrylamide to 200mL of ether and stir to dissolve, then add 12.2g of salicylaldehyde to it, raise the temperature to 60-65°C, stir and react for 5-6h, then cool down to room temperature, filter, wash and dry to obtain product A;

[0036] ②Put 12mL of concentrated hydrochloric acid, 8g of paraformaldehyde and 150mL of dioxane into the reaction kettle at the same time, then add 10g of product A into it, stir and mix for 3-5min, then add 4.7g of 2-chloro-4 , 6-bis(ethylamino)-1,3,5-triazine, keep the amount of each addition at 100-150mg, the interval between each addition is 10-12min, after the addition is complete, control the temperature and stir React for 40-45h, then heat up to 50-60°C and reflux for 8-10h, then evaporate to remove the solvent, then wash the evaporated product with 5% sodium hydroxide solution and deionized to neutral Finally, wash with acetone for 3-5 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com