Bamboo-plastic composite material

A composite material and bamboo-plastic technology, applied in the field of bamboo-plastic composite materials, can solve the problems of environmental pollution, non-degradable plastics, and low added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

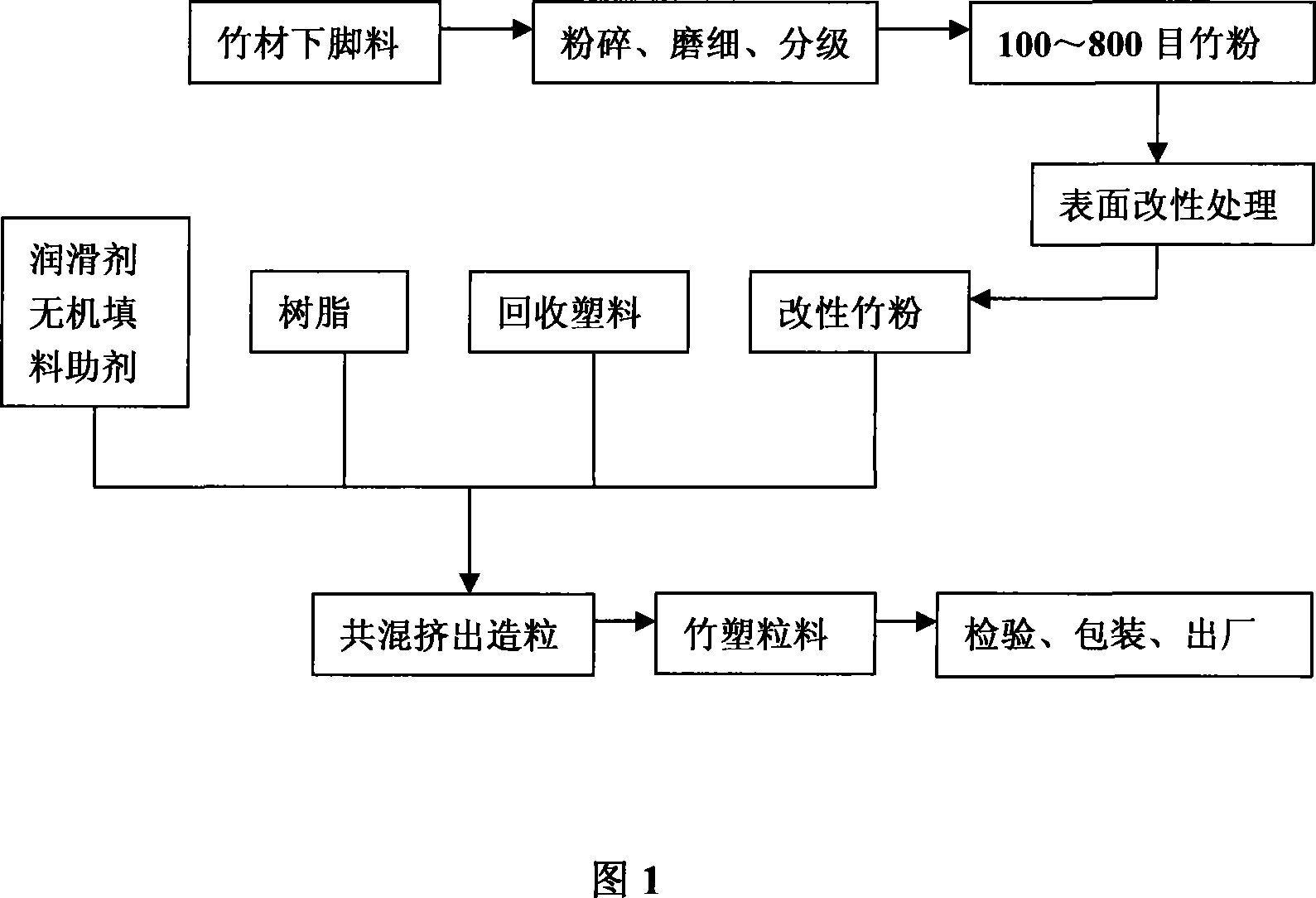

Method used

Image

Examples

example 1

[0045] Example 1. Bamboo-plastic board pellets

[0046] Formula (weight fraction):

[0047] Polyethylene resin 60~80

[0048] Waste polyethylene pellets 40~20

[0049] Bamboo powder 100 mesh to 800 mesh 80 to 120

[0050] Modifier 10~15

[0051] Calcium carbonate >1250 mesh 5~10

[0052] Stearic acid Industrial grade 5~10

[0053] Zinc stearate Industrial grade 1.0~1.5

[0054] Polyethylene wax industrial grade 2~6

[0055] Other additives 5~15

[0056] The auxiliary agent is flame retardant, antistatic agent, coloring agent or antifungal agent, the same below.

example 2

[0057] Example 2. Bamboo-plastic pipe pellets

[0058] Formula (weight fraction):

[0059] Polyvinyl chloride resin 60~80

[0060] Waste polyvinyl chloride pellets 40~20

[0061] Bamboo powder 100 mesh to 800 mesh 80 to 120

[0062] Modifier 10~15

[0063] Calcium carbonate >1250 mesh 10~25

[0064] Stearic acid Industrial grade 5~10

[0065] Zinc stearate Industrial grade 1.0~1.5

[0066] Polyethylene wax Industrial grade 2~5

[0067] Chlorinated polyethylene Industrial grade 5~10

[0068] Heat stabilizer Industrial grade 5~10

[0069] Other additives Industrial grade 5~15

example 3

[0070] Example 3. Bamboo plastic profile pellets

[0071] Formula (weight fraction):

[0072] Polyvinyl chloride resin 60~80

[0073] Waste polyvinyl chloride pellets 40~20

[0074] Bamboo powder 100 mesh to 800 mesh 80 to 120

[0075] Modifier 10~15

[0076] Calcium carbonate >1250 mesh 10~25

[0077] Stearic acid Industrial grade 5~10

[0078] Zinc stearate Industrial grade 1.0~1.5

[0079] Polyethylene wax Industrial grade 5~10

[0080] EVA resin 5~10

[0081] Heat stabilizer Industrial grade 5~10

[0082] Other additives 5~15

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com