Steel construction reinforced structure and reinforcing method thereof

A steel structure building and reinforcement structure technology, which is applied in the direction of building structure, construction, building maintenance, etc., can solve the problems of deformation of steel components, difficulty in construction, and difficulty in meeting the design requirements for the anti-slip coefficient, so as to improve the construction period, The simplification and improvement of construction technology and the effect of strong construction operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

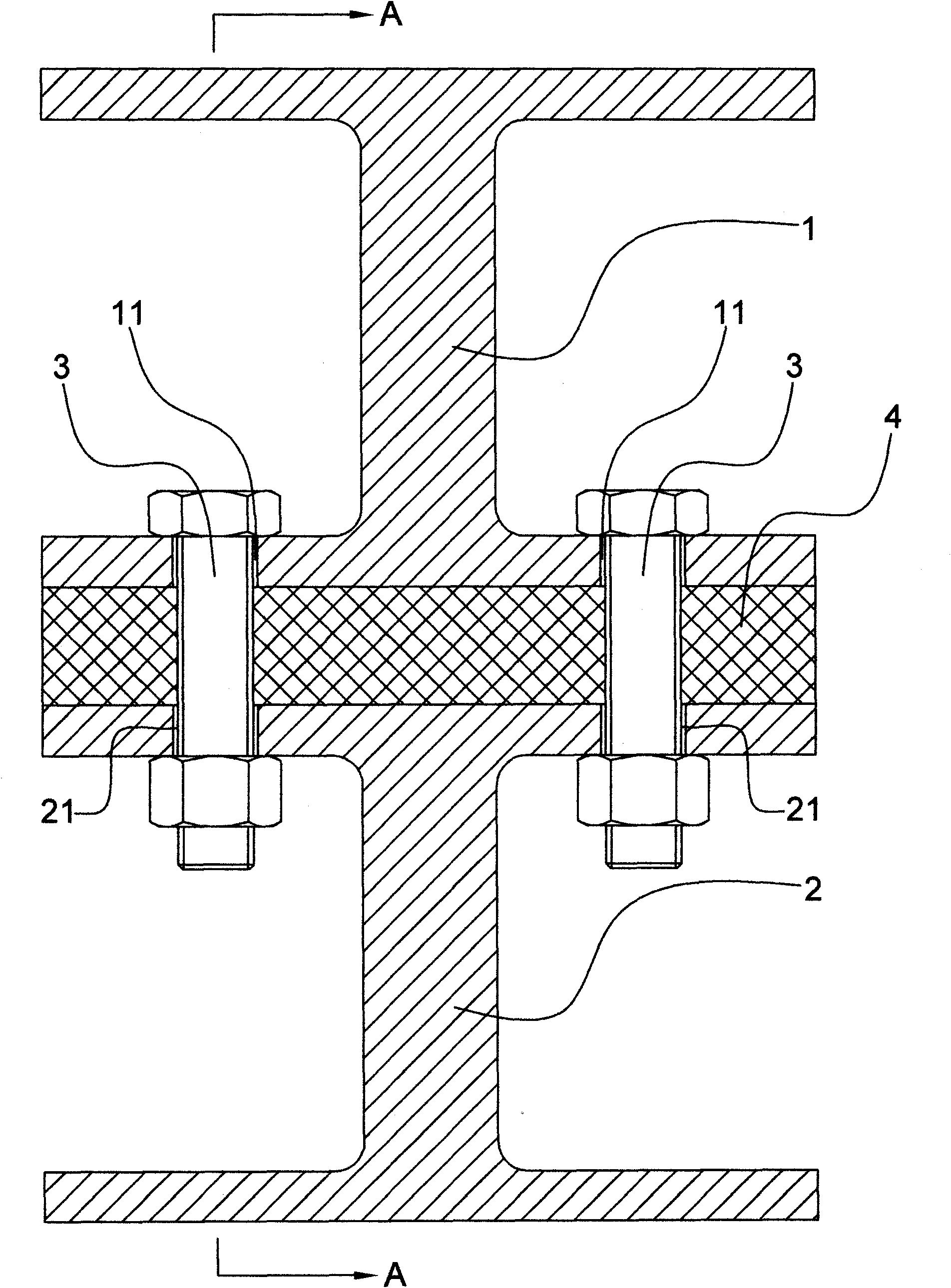

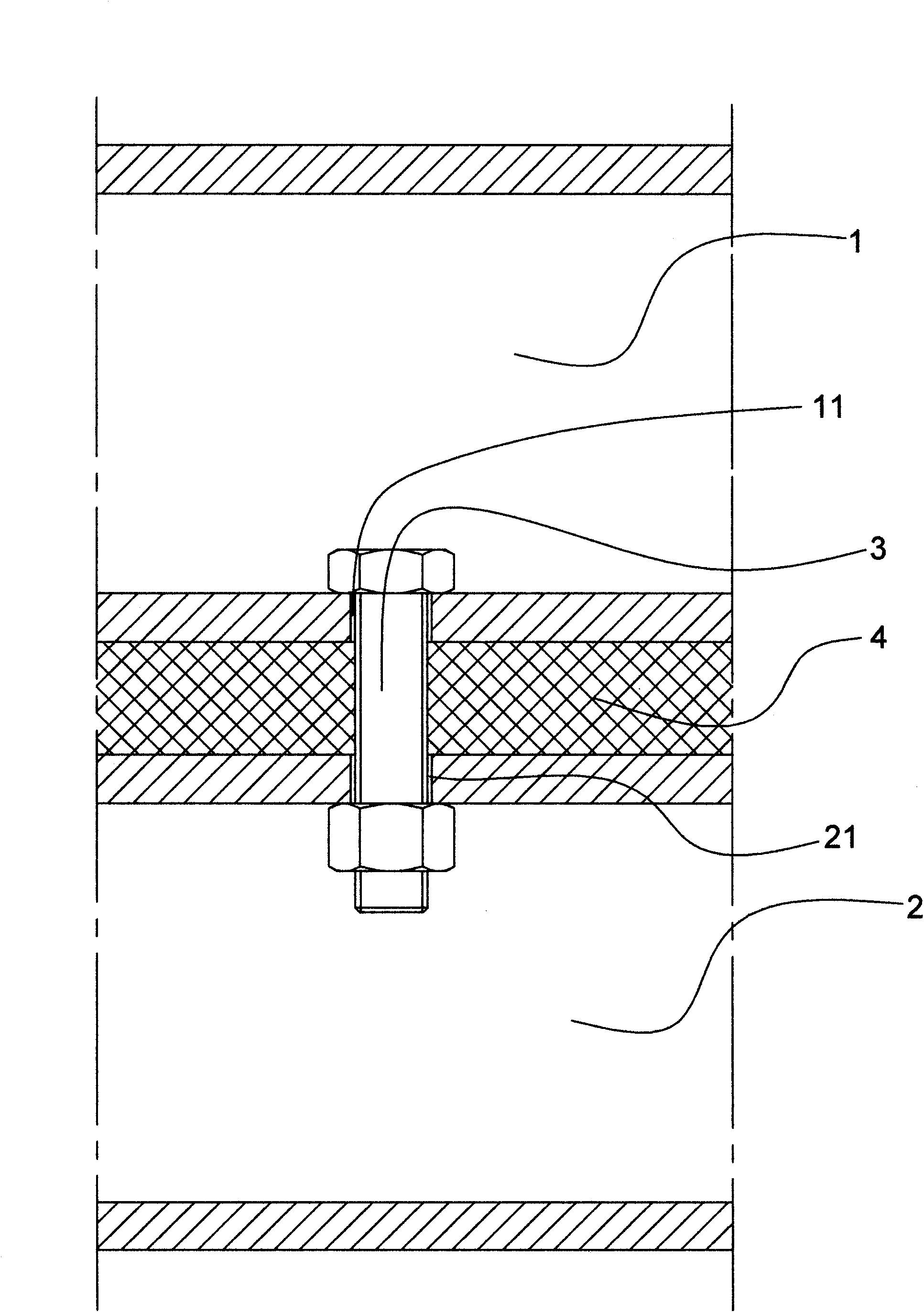

[0022] see figure 1 , figure 2 , a reinforced structure of a steel structure building, comprising an original structural steel 1, a reinforced steel 2, and a reinforced bolt 3, the reinforced bolt 3 passes through the through hole 11 on the original structural steel 1 and the through hole 21 on the reinforced steel 2, and the original The structural steel 1 and the reinforced steel 2 are fastened and connected, which is characterized in that a structural adhesive bonding layer 4 is provided between the original structural steel plate 1 and the reinforced steel plate 2 .

[0023] Preferably, the thickness of the structural adhesive bonding layer 4 is 2-5 mm.

[0024] Preferably, the diameters of the through hole 11 on the original structural steel 1 and the through hole 21 on the reinforced steel 2 are both 1-2 mm larger than the nominal diameter of the reinforced bolt 3 .

Embodiment 2

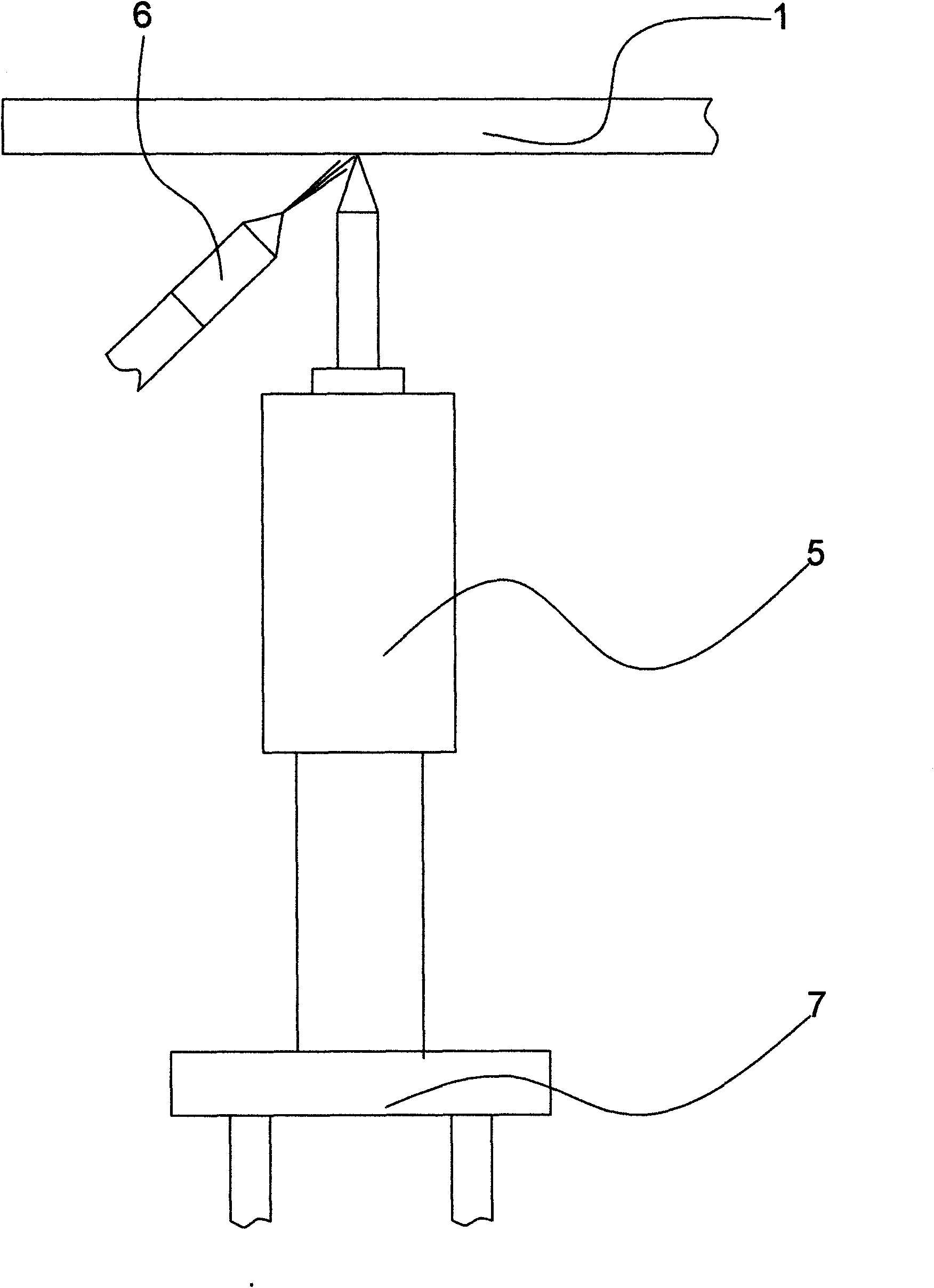

[0026] see figure 1 , figure 2 , image 3 , the construction method of building reinforcement structure is characterized in that comprising the following steps:

[0027] a. Drilling

[0028] First, build the support 7 of the engineering drill 5 under the original structural steel plate 1, place the engineering drill 5 on the support 7, make the drill bit of the engineering drill 5 align with the drilling position under the original structural steel plate 1, start the engineering drill 5, and carry out Reverse drilling, while drilling, use water spray device 6 to spray water to the drill hole, spray water while drilling, so that the water column sprayed by water spray device 6 is directly sprayed on the drill hole until the original structural steel plate is drilled 1. Form the through hole 11; drill all the holes by analogy, and make the position of the through hole 11 on the original structural steel plate 1 correspond to the position of the pre-processed through hole 21 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com