Corrosion-resistant cooling structure for offshore wind turbine

A technology for wind turbines and cooling structures, applied in wind turbine components, wind turbines, wind power generation, etc., can solve problems such as increasing operating costs, hazards, and difficulty in control, and achieve a reduction in anti-corrosion levels, cost reduction, and realization of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

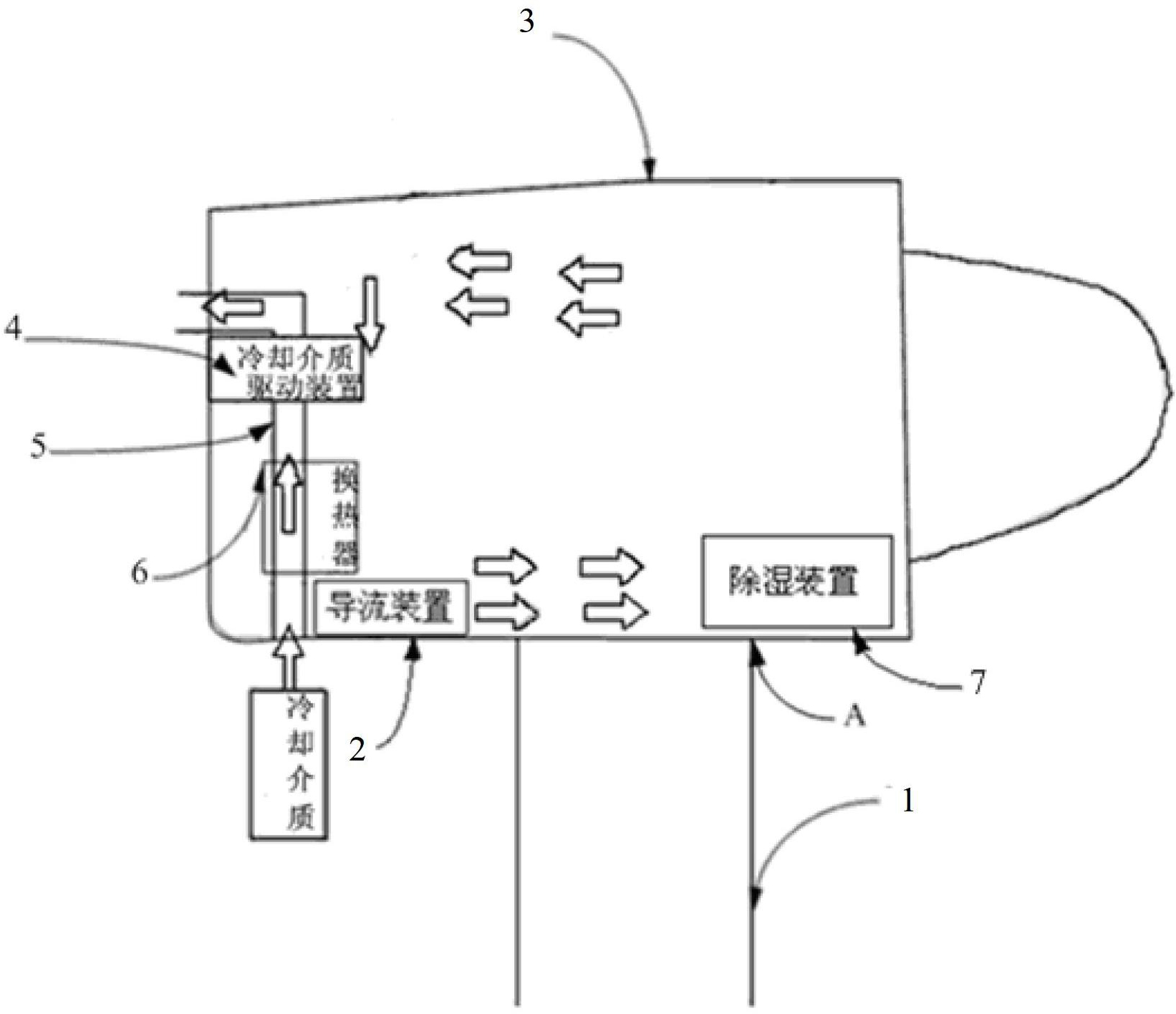

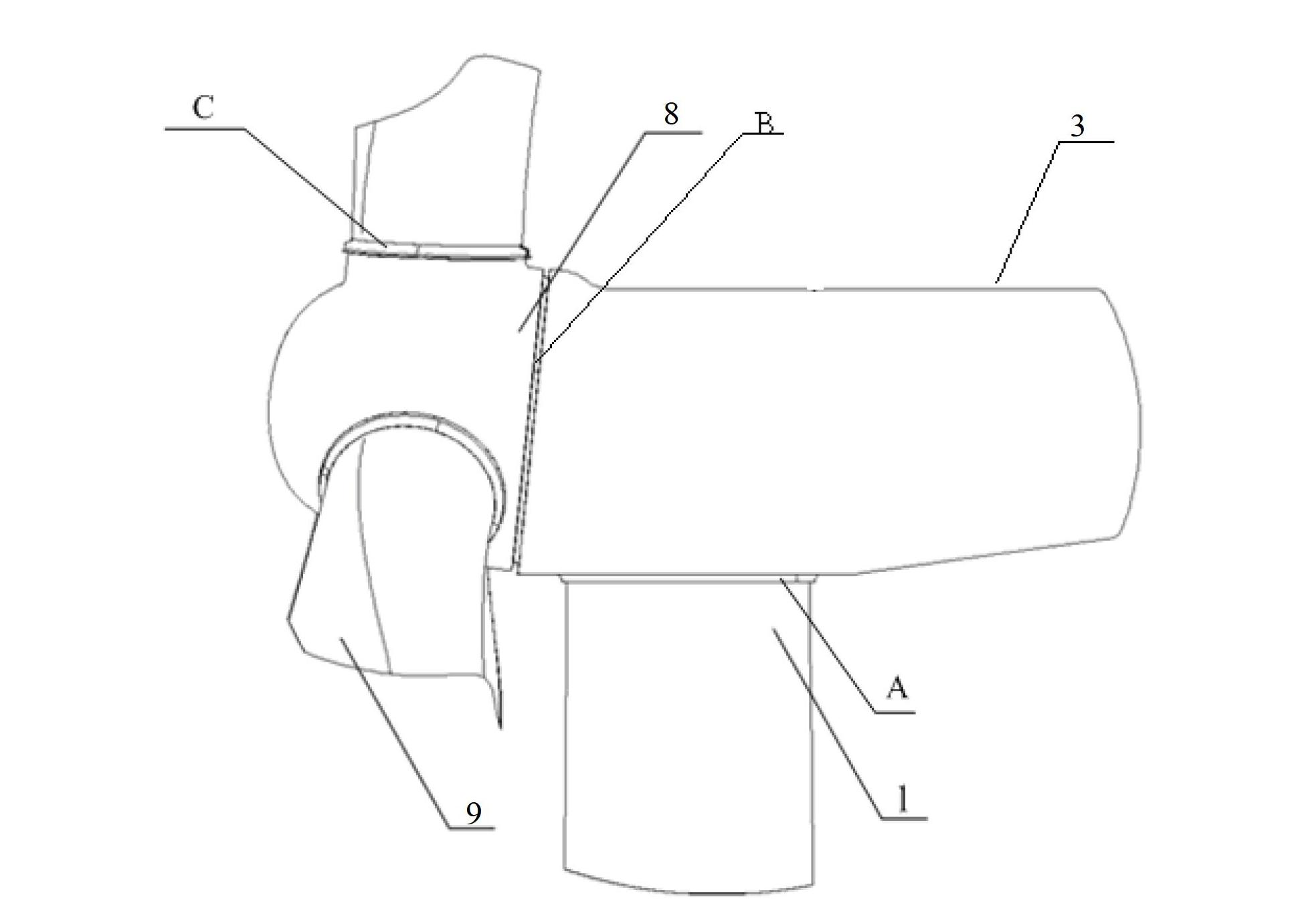

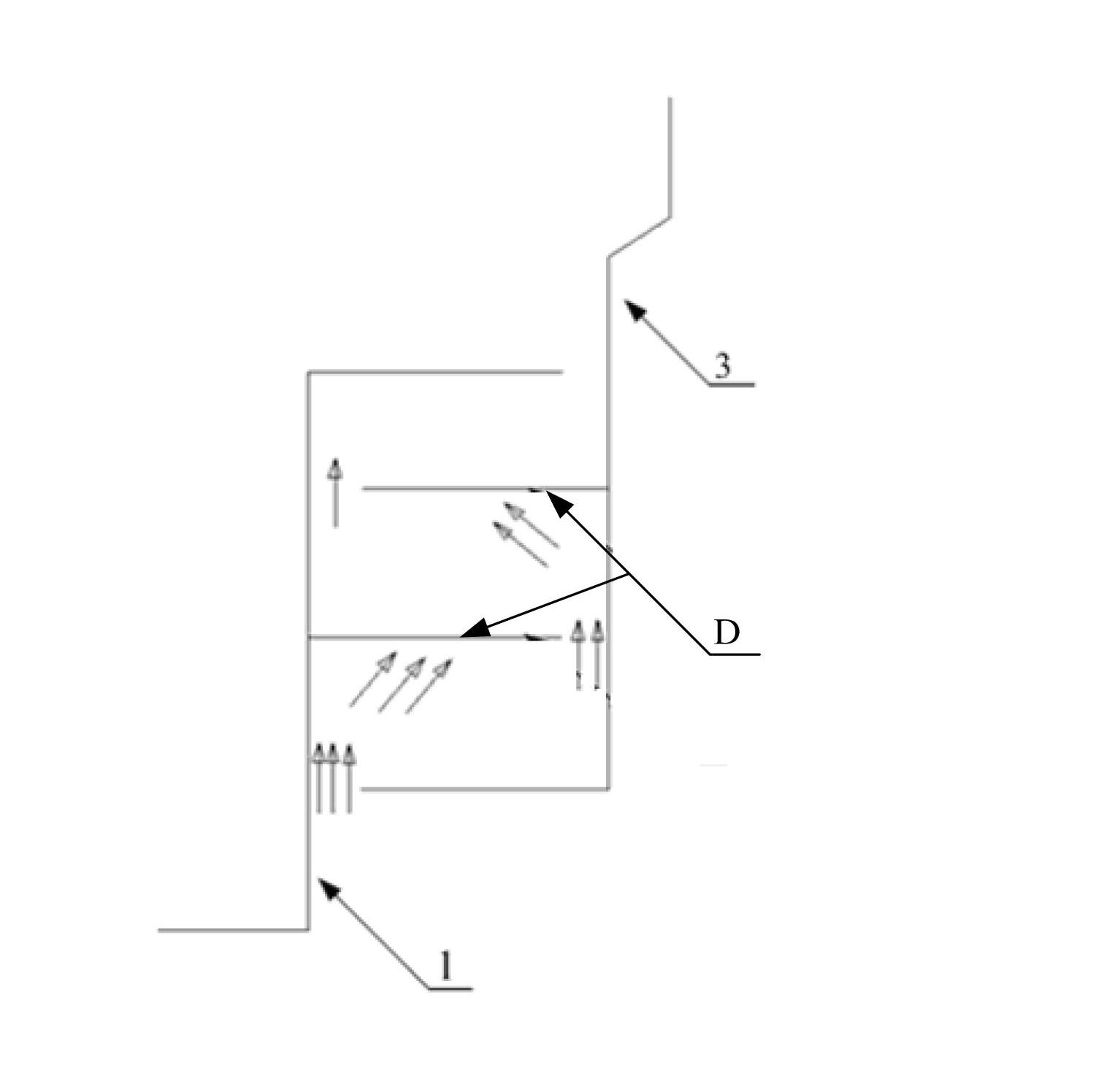

[0031] The core of the present invention is to provide an anti-corrosion cooling structure for offshore wind power generators. In the cooling structure, the matching parts of the nacelle and the tower and the mating parts of the nacelle and the main shaft are all sealed in the way of labyrinth sealing, and the airtight The air cooling system is installed in the cabin, so as to ensure that the inside of the cabin can be cooled and at the same time realize the overall sealing of the cabin, the parts inside the cabin are isolated from the outside air, and the parts inside the cabin are protected from the influence of corrosive substances in the outside air , so the corrosion resistance level of the internal parts of the engine room can be moderately reduced, and the cost of parts can be reduced.

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com