Graphene self-lubricating wear-resistant corrosion-resistant scale-inhibiting wax coating agent and preparation method thereof

A coating agent and graphene technology, applied in anti-corrosion coatings, coatings, etc., to achieve the effects of delaying the formation of scale wax, reducing the accumulation rate, and slowing down the phenomenon of wax separation and wall hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

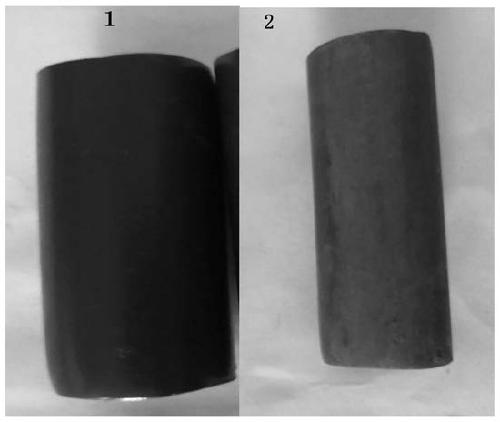

Image

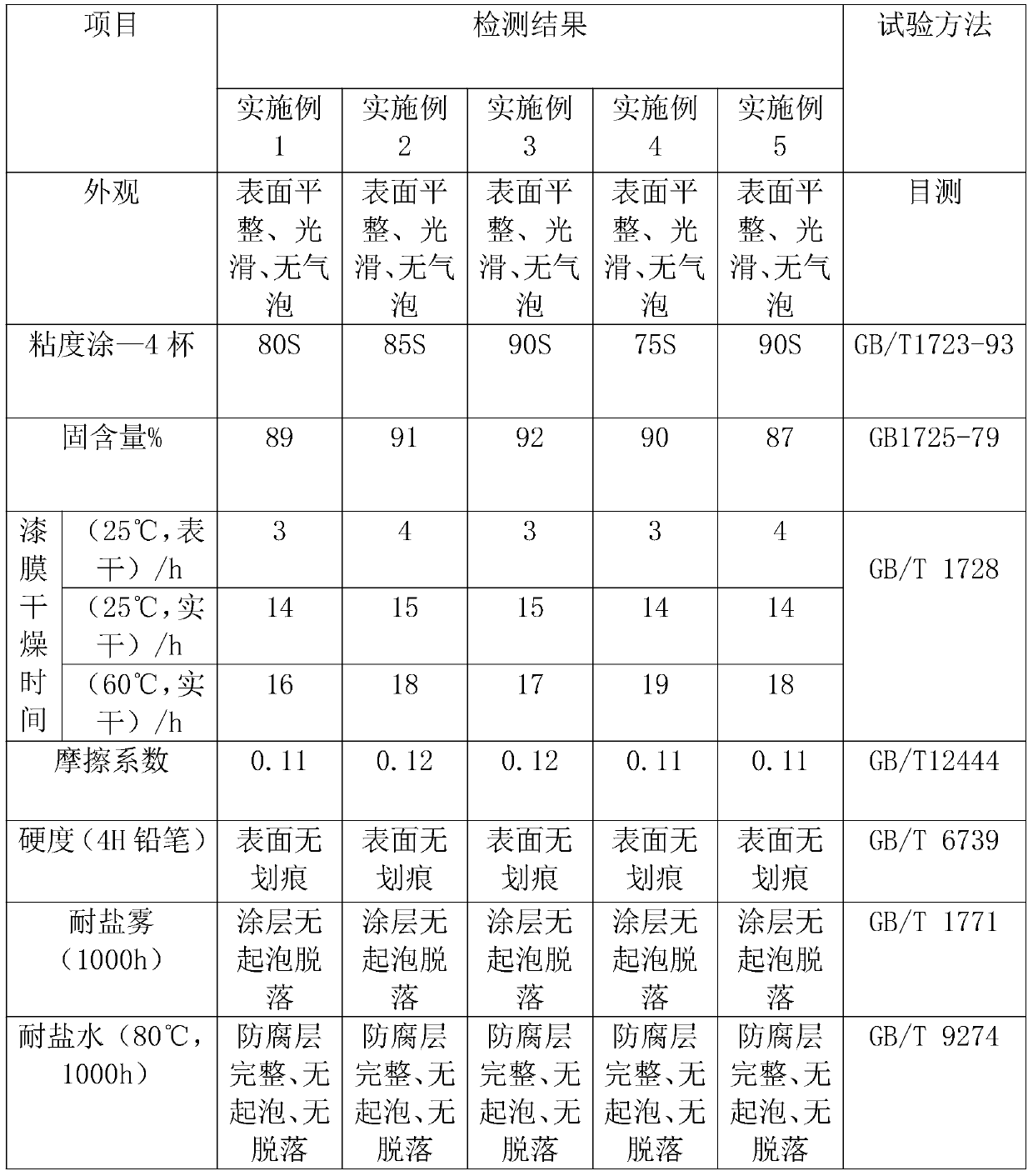

Examples

Embodiment 1

[0029] (1) Weigh 5 grams of graphene, 15 grams of tetrafluoroethylene / hexafluoropropylene copolymer, 5 grams of tungsten disulfide, 12 grams of bronze powder, 35 grams of acetone, 1 gram of triethanolamine sulfate alkyl ether, hydroxyethyl acrylate 1 gram of ester, 5 grams of hydrogenated castor oil.

[0030] (2) Acetone is divided into the first part and the second part, and the copolymer of tetrafluoroethylene / hexafluoropropylene, tungsten disulfide, bronze powder, the first part of acetone, triethanolamine sulfate alkyl ether, and hydroxyethyl acrylate are mixed, Disperse evenly with a disperser, the speed of the disperser is 1300 rpm, and the dispersion time is 10 minutes, and grind to 5 microns with a sand mill to obtain the first mixture, which is set aside;

[0031] (3) Hydrogenated castor oil and the second part of acetone are dispersed evenly with a disperser, the weight ratio of the first part of acetone and the second part of acetone is 2:1, the speed of the dispers...

Embodiment 2

[0034] (1) Weigh 6 grams of graphene, 18 grams of tetrafluoroethylene / fluoroalkyl vinyl ether copolymer, 6 grams of tungsten disulfide, 13 grams of bronze powder, 36 grams of butanone, 2 grams of alkylammonium sulfate, acrylic acid 1 gram of hydroxypropyl ester, 6 grams of organic bentonite.

[0035](2) Divide methyl ethyl ketone into the first part and the second part, the copolymer of tetrafluoroethylene / fluoroalkyl vinyl ether, tungsten disulfide, bronze powder, the first part butanone, alkyl ammonium sulfate, hydroxypropyl acrylate Mix the esters, disperse evenly with a disperser, the speed of the disperser is 1300 rpm, and the dispersion time is 11 minutes, and grind to 6 microns with a sand mill to obtain the first mixture, which is set aside;

[0036] (3) Mix the organic bentonite and the second part of butanone, and disperse evenly with a disperser, the weight ratio of the first part of butanone and the second part of butanone is 2:1, the speed of the disperser is 1300...

Embodiment 3

[0039] (1) Weigh 7 grams of graphene, 25 grams of tetrafluoroethylene / hexafluoropropylene / fluoroalkyl vinyl ether copolymer, 7 grams of tungsten disulfide, 13 grams of bronze powder, 38 grams of propylene glycol, ammonium alkyl ether sulfate 3 grams, 2 grams of 2-acrylamide-2-methylpropanesulfonic acid, 8 grams of fumed silica.

[0040] (2) The propylene glycol is divided into the first part and the second part, and the copolymer of tetrafluoroethylene / hexafluoropropylene / fluoroalkyl vinyl ether, tungsten disulfide, bronze powder, the first part of propylene glycol, ammonium alkyl ether sulfate, Mix 2-acrylamide-2-methylpropanesulfonic acid, disperse evenly with a disperser, the speed of the disperser is 1400 rpm, and the dispersion time is 13 minutes, and grind to 8 microns with a sand mill to obtain the first mixture, which is set aside ;

[0041] (3) Mix fumed silica and the second part of propylene glycol, and disperse evenly with a disperser, the weight ratio of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com