Device and method for preventing mildew and corrosion of plate

A technology for anti-corrosion devices and boards, which is applied in wood treatment, wood heating, wood processing appliances, etc., can solve the problems of difficult air discharge, unstable and uneven quality of anti-corrosion boards, and achieves small heat loss and avoids poor processing. Uniform and fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

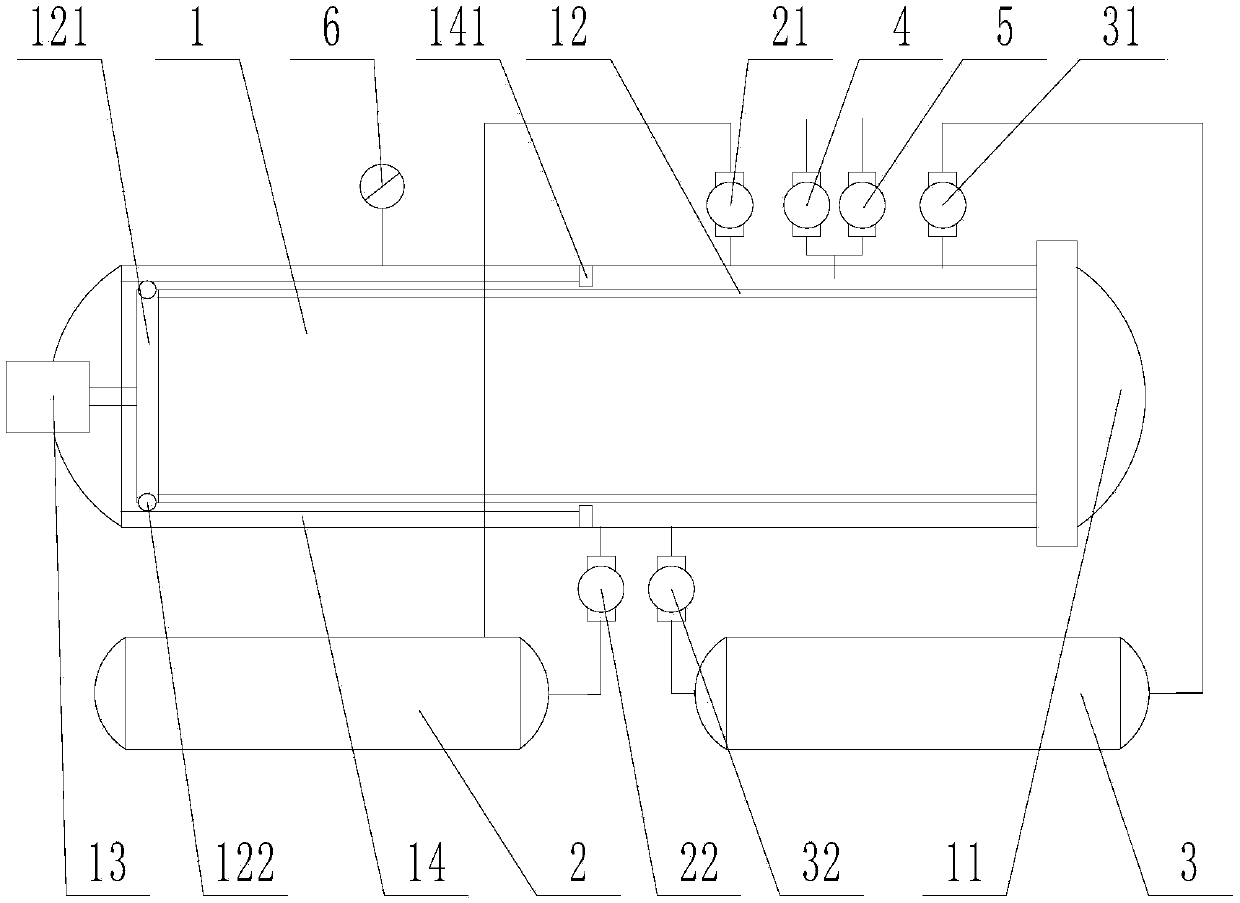

[0069] A plate anti-mildew and anti-corrosion device, including a sealed tank, a liquid storage tank and an air storage tank;

[0070] An air port is provided on the sealed tank, and a vacuum pump and a booster pump are respectively connected to the air port;

[0071] The sealed tank is also provided with a liquid inlet and a liquid outlet, the liquid inlet is connected with the liquid storage tank through the liquid inlet pump, and the liquid discharge port is connected with the liquid storage tank through the liquid discharge pump; the liquid storage The tank contains anti-corrosion liquid;

[0072] The airtight tank is also provided with an air inlet and an air outlet, the air inlet is connected to the air storage tank through an air intake pump, and the air outlet is connected to the air storage tank through an exhaust pump; Has anti-corrosion gas;

[0073] A valve body is respectively arranged between the vacuum pump, the booster pump, the liquid inlet pump, the liquid ...

Embodiment 2

[0080] A method for anti-mildew and anti-corrosion of boards, comprising:

[0081] Step 1. Put the board in the sealed tank, rotate the board, vacuum the inside of the sealed tank to 0.03MPa, and heat the water molecules in the board by microwave at the same time for 20 minutes;

[0082] Step 2. Inject anti-corrosion gas into the sealed tank, and pressurize, adjust the pressure to 1.0MPa, and keep it for 50 minutes;

[0083] Step 3. First adjust the pressure in the sealed tank to 0.1MPa, then inject the antiseptic liquid mixed with oil-based preservatives, organic solvent preservatives and waterborne preservatives into the sealed tank, and pressurize the sealed tank. Adjust the pressure to 0.8MPa and keep it for 2-8 hours;

[0084] Step 4. Drain the antiseptic liquid in the sealed tank of step 3, heat the board to 170°C, and dry the wood until it is absolutely dry; then lower the temperature to 110°C and keep it for 2 hours. The pressure of the cage sealed tank during heat tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com