Polyvinyl butyral solution bonded lead oxide ceramic for solid oxygen control and preparation method of polyvinyl butyral solution bonded lead oxide ceramic

A polyvinyl butyral and lead oxide technology, applied in the field of cermets, can solve the problems of cracks in the equatorial position of PbO spheres, inability of liquid lead-bismuth loop to act as an oxygen source, and inability to maintain the integrity of the shape, etc., and achieve the microscopic shape of ceramics. Good, good oxygen supply performance of ceramics, strong bonding force between grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

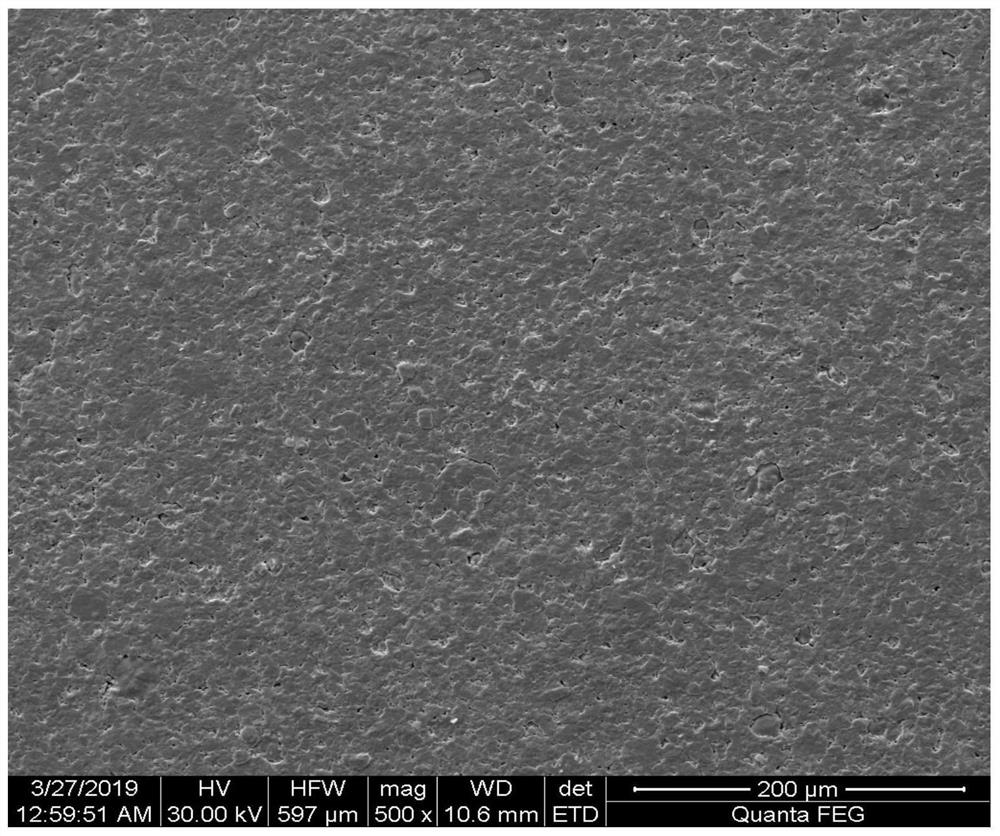

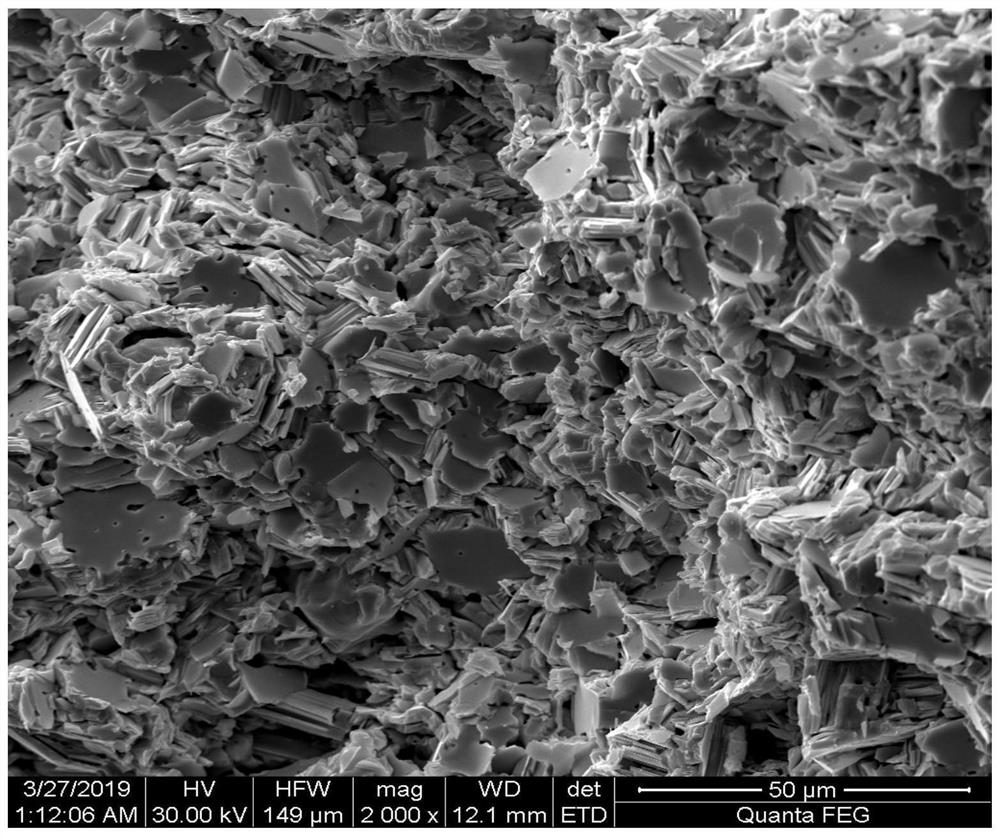

[0043] PVB solution-bonded lead oxide ceramics were prepared as follows:

[0044] 1) configure PVB solution, PVB powder 4wt% and dehydrated alcohol 96wt% in the PVB solution; Add PVB solution in the PbO powder, the PVB solution quality is 4wt% of PbO powder, fully mixes, grinds evenly, obtains mixture; PbO powder and The purity of PVB powder is greater than 99wt%;

[0045] 2) Pre-compress the mixture obtained in step 1) for 2 minutes under a pressure of 10 MPa to obtain a pre-compressed tablet, and then re-grind to obtain a more uniform mixed powder, and then pass through a 50-mesh sieve to increase the fluidity of the pellets and increase the bulk density;

[0046] 3) Pour the mixed powder obtained in step 2) into a metal mold, pressurize, maintain pressure and release pressure to obtain a ceramic compact; adopt a rate of less than 0.3MPa / s to pressurize to 45MPa, maintain pressure for 3min, and then Release pressure at a rate of 0.1MPa / s;

[0047] 4) Put the ceramic compac...

Embodiment 2

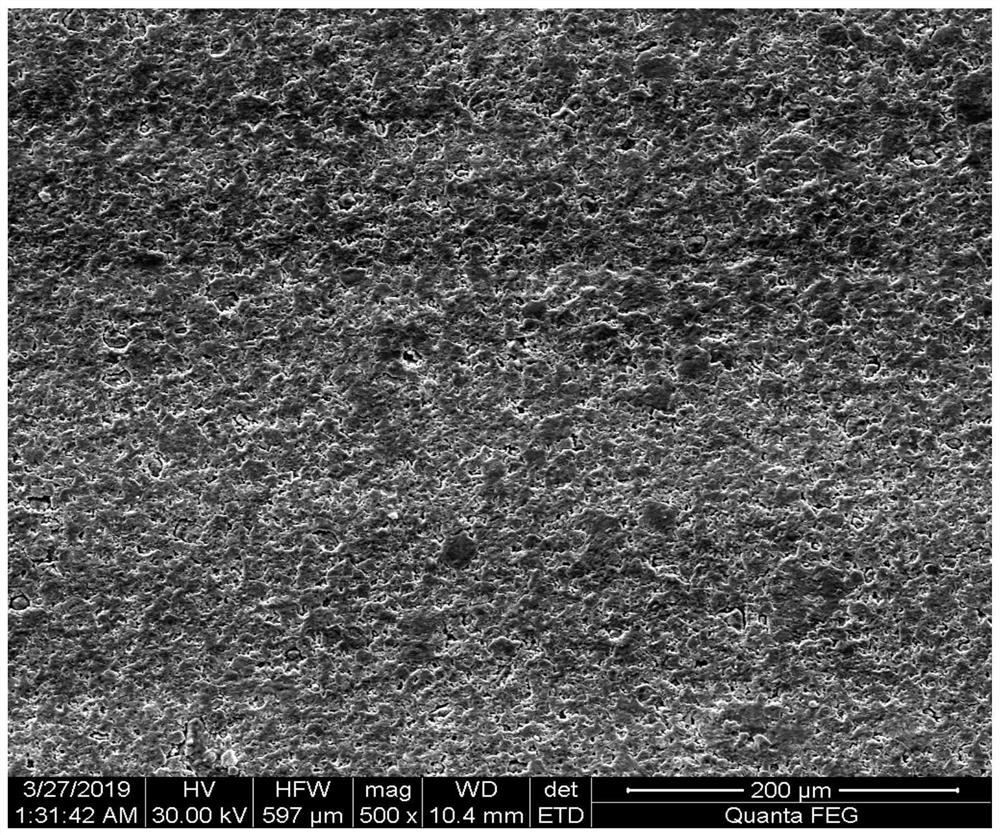

[0052] The lead oxide ceramics bonded by PVB solution is prepared according to the same process as in Example 1, wherein the PVB solution is added in an amount of 2wt% of the PbO powder, and sintered at 620°C in a conventional muffle furnace to obtain a bonded 2wt% PVB solution. lead oxide ceramics.

Embodiment 3

[0054] The lead oxide ceramics bonded by PVB solution is prepared according to the same process as in Example 1, wherein the PVB solution is added in an amount of 6wt% of the PbO powder, and sintered in a conventional muffle furnace at 620°C to obtain a bonded 6wt% PVB solution. lead oxide ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com